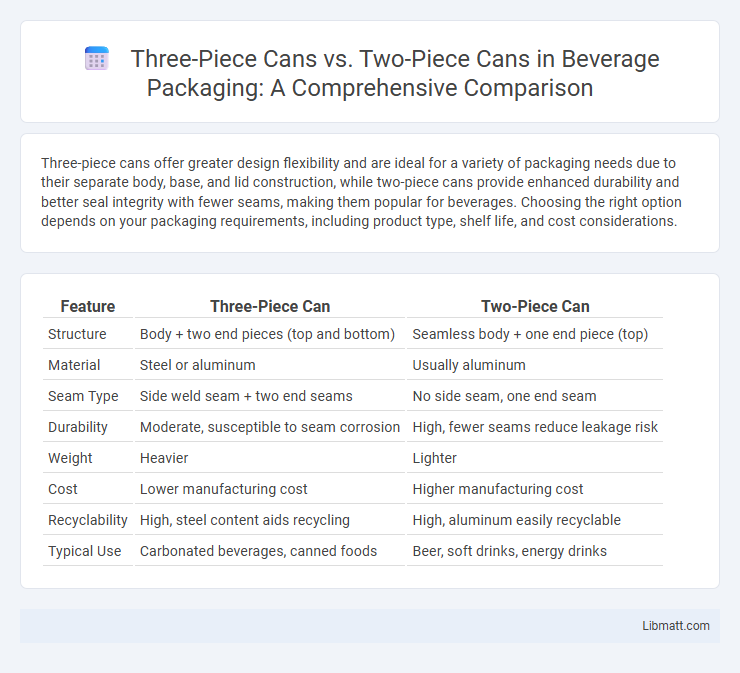

Three-piece cans offer greater design flexibility and are ideal for a variety of packaging needs due to their separate body, base, and lid construction, while two-piece cans provide enhanced durability and better seal integrity with fewer seams, making them popular for beverages. Choosing the right option depends on your packaging requirements, including product type, shelf life, and cost considerations.

Table of Comparison

| Feature | Three-Piece Can | Two-Piece Can |

|---|---|---|

| Structure | Body + two end pieces (top and bottom) | Seamless body + one end piece (top) |

| Material | Steel or aluminum | Usually aluminum |

| Seam Type | Side weld seam + two end seams | No side seam, one end seam |

| Durability | Moderate, susceptible to seam corrosion | High, fewer seams reduce leakage risk |

| Weight | Heavier | Lighter |

| Cost | Lower manufacturing cost | Higher manufacturing cost |

| Recyclability | High, steel content aids recycling | High, aluminum easily recyclable |

| Typical Use | Carbonated beverages, canned foods | Beer, soft drinks, energy drinks |

Overview of Three-Piece and Two-Piece Cans

Three-piece cans consist of a cylindrical body with two separate end pieces, typically made from tin-plated steel or aluminum, providing versatility and ease of manufacturing for large-volume packaging. Two-piece cans are drawn and ironed from a single sheet of metal, usually aluminum, resulting in a seamless body with one end permanently formed, offering superior structural integrity and better appeal for beverages and food products. Both types are widely used in the packaging industry, with three-piece cans favored for cost-efficiency and flexibility, while two-piece cans are preferred for enhanced durability and improved aesthetic qualities.

Manufacturing Processes Compared

Three-piece cans consist of a cylindrical body with a separate top and bottom, joined by welding or soldering, allowing for versatile sizes but requiring more complex sealing processes and higher material use. Two-piece cans are drawn and ironed from a single metal sheet, reducing joints to only the top, which improves structural integrity and minimizes risks of leakage or corrosion. Manufacturing two-piece cans enables faster production rates and better surface treatment options, which enhances durability and consumer safety.

Key Structural Differences

Three-piece cans consist of a cylindrical body and two end pieces, allowing for seamless printing and easy customization, whereas two-piece cans are formed from a single piece with only one separate end, enhancing structural integrity and reducing potential leakage points. The three-piece design incorporates side seams, which can affect durability under pressure, while the two-piece can's seamless body offers superior strength and is better suited for carbonated beverages. Understanding these key structural differences helps you select the appropriate can type for your packaging needs based on product requirements and manufacturing capabilities.

Material Efficiency and Sustainability

Three-piece cans consist of a cylindrical body and two end pieces, typically made from steel or aluminum, which allows for efficient use of raw materials but generates more scrap during manufacturing compared to two-piece cans. Two-piece cans, fabricated using drawn and ironed processes from a single aluminum or steel sheet, offer higher material efficiency by reducing seams and waste, contributing to better sustainability. The seamless design of two-piece cans also enhances recyclability and lowers environmental impact through reduced energy consumption in production and recycling stages.

Application and Usage in Different Industries

Three-piece cans, composed of a cylindrical body with separate lid and bottom ends, are widely used in the food industry for packaging soups, vegetables, and pet food due to their versatility and ability to be shaped into various sizes. Two-piece cans, featuring a one-piece body with an integrated bottom and a separate lid, are popular in the beverage and aerosol industries for their sleek design, improved resistance to leaks, and better suitability for high-pressure contents. Your choice between these can types depends on the specific industry requirements, such as product preservation, production speed, and cost efficiency.

Cost Implications and Production Scalability

Three-piece cans generally have lower tooling and material costs, making them more cost-effective for small to medium production runs, while two-piece cans require higher initial investment but offer economies of scale for large-scale manufacturing. Production scalability favors two-piece cans due to their seamless design, which allows faster production speeds and reduced risk of leakage, enhancing efficiency in high-volume operations. Cost implications for maintenance and changeover times also tend to be lower with two-piece cans, supporting scalability in automated production lines.

Sealing and Leakage Resistance

Three-piece cans feature a side seam created by welding or soldering, which can pose a higher risk of leakage if not properly sealed, whereas two-piece cans are seamless, enhancing their sealing integrity and reducing the potential for leaks. The one-piece body and bottom design of two-piece cans eliminate side seams, resulting in superior resistance to leakage and improved durability under pressure. Your choice between the two depends on the required sealing performance and product compatibility.

Printability and Branding Opportunities

Three-piece cans offer superior printability due to their flat side panels, providing expansive surfaces for high-quality, detailed graphics and vibrant branding, enhancing product visibility on shelves. In contrast, two-piece cans have a more cylindrical shape with fewer uninterrupted print areas, which can limit the complexity and size of printed designs. This makes three-piece cans more advantageous for brands seeking extensive customization and eye-catching packaging to strengthen consumer recognition.

Environmental Impact and Recycling

Three-piece cans, typically made from steel with a welded or soldered seam, present greater challenges in recycling due to their mixed material composition and potential for contamination in the recycling stream. Two-piece cans, usually constructed entirely from aluminum or tinplate steel without a side seam, offer superior recyclability as their uniform material facilitates efficient processing and reduces energy consumption. Research demonstrates that two-piece cans have a lower environmental footprint, with a significant reduction in greenhouse gas emissions and resource usage compared to three-piece cans, making them a more sustainable packaging choice.

Future Trends in Can Manufacturing

Three-piece cans continue to evolve with innovations in sealing technology and sustainable materials, while two-piece cans gain traction due to their lightweight design and enhanced recyclability. You can expect future trends to emphasize eco-friendly coatings and automation in production processes to reduce costs and environmental impact. Advances in smart packaging are also being integrated to improve supply chain visibility for both types of cans.

Three-piece can vs two-piece can Infographic

libmatt.com

libmatt.com