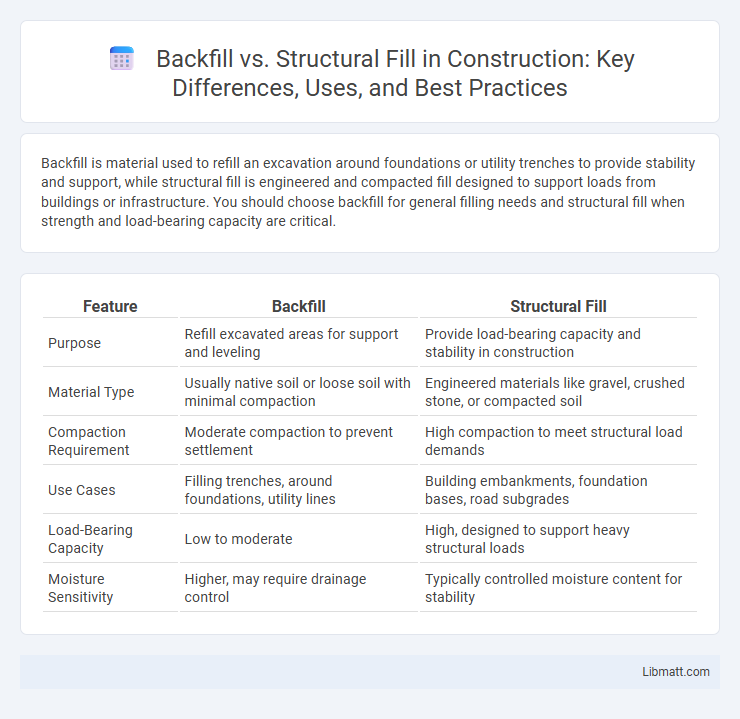

Backfill is material used to refill an excavation around foundations or utility trenches to provide stability and support, while structural fill is engineered and compacted fill designed to support loads from buildings or infrastructure. You should choose backfill for general filling needs and structural fill when strength and load-bearing capacity are critical.

Table of Comparison

| Feature | Backfill | Structural Fill |

|---|---|---|

| Purpose | Refill excavated areas for support and leveling | Provide load-bearing capacity and stability in construction |

| Material Type | Usually native soil or loose soil with minimal compaction | Engineered materials like gravel, crushed stone, or compacted soil |

| Compaction Requirement | Moderate compaction to prevent settlement | High compaction to meet structural load demands |

| Use Cases | Filling trenches, around foundations, utility lines | Building embankments, foundation bases, road subgrades |

| Load-Bearing Capacity | Low to moderate | High, designed to support heavy structural loads |

| Moisture Sensitivity | Higher, may require drainage control | Typically controlled moisture content for stability |

Understanding Backfill and Structural Fill

Backfill refers to the material used to refill an excavation around foundations or trenches to provide support and stability, often consisting of soil, gravel, or crushed stone. Structural fill is an engineered material specifically designed to meet load-bearing and compaction requirements in construction projects, ensuring proper foundation support and minimizing settlement. Understanding the differences between your backfill and structural fill choices is crucial for optimizing site stability and long-term durability.

Key Differences Between Backfill and Structural Fill

Backfill refers to the soil or material used to refill an excavation site, primarily for support and stability, while structural fill is engineered and compacted to provide load-bearing capacity and reduce settlement. Backfill often consists of native or less controlled materials, whereas structural fill involves carefully selected and tested aggregates to meet specific engineering criteria. The key differences lie in their purpose, material quality, and compaction requirements, with structural fill designed to withstand higher loads and improve foundation performance.

Common Materials Used in Backfill

Common materials used in backfill include gravel, sand, crushed stone, and native soil, chosen for their compaction properties and drainage capabilities. Proper selection of backfill material ensures stability and prevents settlement or water accumulation around foundations, pipes, and other structures. You should consider the specific project requirements and environmental conditions to optimize performance and longevity of the backfill.

Typical Materials for Structural Fill

Typical materials for structural fill include well-graded gravel, crushed stone, and engineered fill composed of compacted soil mixed with stabilizers such as cement or lime. These materials are chosen for their high load-bearing capacity, low compressibility, and controlled compaction properties to support structural loads effectively. Unlike random backfill, structural fill requires strict quality control to ensure stability and prevent settlement in construction projects.

Applications of Backfill in Construction

Backfill is essential in construction for filling excavated areas around foundations, underground utilities, and retaining walls, providing support and stability to these structures. Common applications include trench backfilling for pipelines, foundation backfilling to prevent soil erosion, and filling voids to enhance ground compaction. Proper selection of backfill material ensures adequate drainage and load-bearing capacity, protecting your construction project from settlement and structural damage.

Structural Fill Uses in Engineering Projects

Structural fill is commonly used in engineering projects to provide a stable foundation for roads, bridges, and buildings by improving load-bearing capacity and reducing settlement. It typically consists of compacted granular materials such as gravel or crushed stone, engineered to meet specific compaction and drainage requirements. Your project's stability and longevity can be enhanced by selecting appropriate structural fill materials that align with soil conditions and design specifications.

Compaction Requirements: Backfill vs Structural Fill

Backfill requires moderate compaction to stabilize soil around structures, typically achieving 90-95% of the maximum dry density as per ASTM D698 standards. Structural fill demands higher compaction levels, often 95-98% of maximum dry density, to support heavy loads and prevent settlement in foundations, roads, or retaining walls. Proper moisture content control is essential in both applications to maximize soil density and ensure long-term stability.

Cost Considerations for Backfill and Structural Fill

Cost considerations for backfill and structural fill vary based on material type, compaction requirements, and project scale. Backfill typically involves lower-cost materials such as native soil or granular materials, resulting in reduced transportation and procurement expenses, while structural fill demands engineered materials with higher compaction standards to support loads, increasing both material and labor costs. Proper selection of fill type influences Your overall project budget by balancing material properties with site-specific engineering requirements.

Performance and Load-Bearing Capabilities

Backfill and structural fill differ significantly in performance and load-bearing capabilities, with structural fill designed to support heavier loads and provide greater stability for foundations and retaining walls. Backfill is typically used to refill excavated areas and may consist of less compacted, granular materials with lower strength, making it less suitable for load-bearing purposes. Your project's safety and durability depend on selecting structural fill when enhanced compaction, strength, and load distribution are critical.

Selecting the Right Fill Material for Your Project

Selecting the right fill material depends on the specific requirements of your construction project, such as load-bearing capacity and drainage needs. Backfill is typically used to refill trenches or around foundations and requires compacted, well-graded soil to ensure stability and prevent settlement. Structural fill, often consisting of engineered materials like crushed stone or gravel, provides enhanced support and load distribution for heavy structures or roadways.

Backfill vs Structural fill Infographic

libmatt.com

libmatt.com