A ballasted roof uses heavy materials like gravel or pavers to hold the roofing membrane in place, providing excellent wind resistance and protection from UV rays while allowing easier roof repairs. Your choice between a ballasted roof and a mechanically attached roof depends on factors like building structure, climate, and maintenance preferences, as mechanically attached roofs offer quicker installation and lighter weight but may be more vulnerable to wind uplift.

Table of Comparison

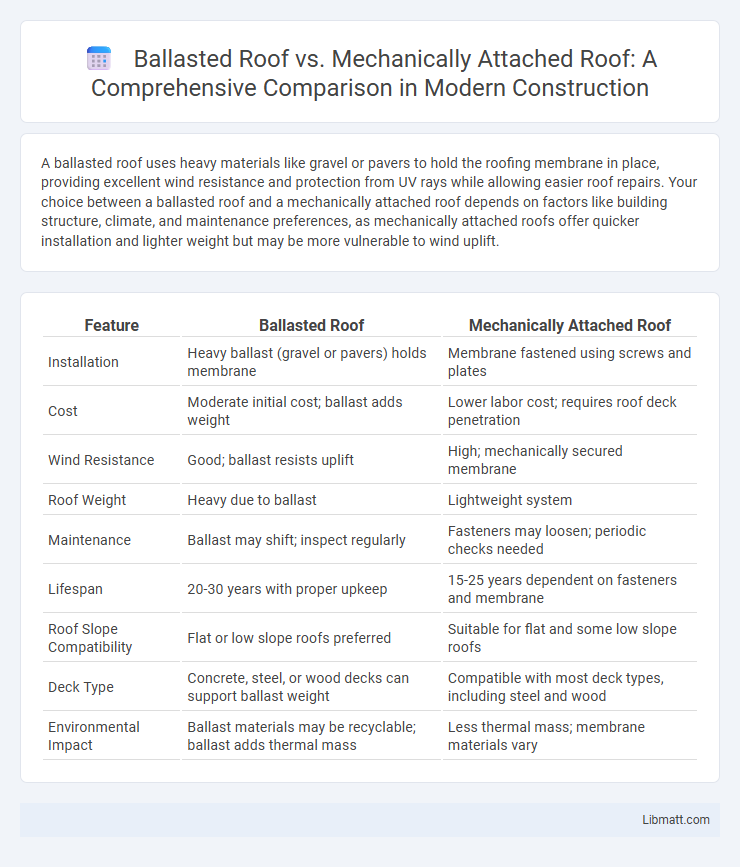

| Feature | Ballasted Roof | Mechanically Attached Roof |

|---|---|---|

| Installation | Heavy ballast (gravel or pavers) holds membrane | Membrane fastened using screws and plates |

| Cost | Moderate initial cost; ballast adds weight | Lower labor cost; requires roof deck penetration |

| Wind Resistance | Good; ballast resists uplift | High; mechanically secured membrane |

| Roof Weight | Heavy due to ballast | Lightweight system |

| Maintenance | Ballast may shift; inspect regularly | Fasteners may loosen; periodic checks needed |

| Lifespan | 20-30 years with proper upkeep | 15-25 years dependent on fasteners and membrane |

| Roof Slope Compatibility | Flat or low slope roofs preferred | Suitable for flat and some low slope roofs |

| Deck Type | Concrete, steel, or wood decks can support ballast weight | Compatible with most deck types, including steel and wood |

| Environmental Impact | Ballast materials may be recyclable; ballast adds thermal mass | Less thermal mass; membrane materials vary |

Introduction to Ballasted and Mechanically Attached Roof Systems

Ballasted roof systems use heavy materials like gravel or pavers to hold the roofing membrane in place, providing excellent protection against wind uplift and UV damage. Mechanically attached roof systems rely on fasteners and plates to secure the roofing membrane directly to the roof deck, offering greater flexibility in installation and adaptability to various roof slopes. Choosing between ballasted and mechanically attached roofs depends on your building structure, weather exposure, and maintenance preferences.

Key Differences Between Ballasted and Mechanically Attached Roofs

Ballasted roofs rely on heavy materials like gravel or pavers to secure the roofing membrane, providing stability through weight, while mechanically attached roofs use fasteners to directly anchor the membrane to the roof deck, ensuring a more secure fit. Ballasted systems typically offer easier installation and lower initial costs but may require additional structural support due to their weight, whereas mechanically attached roofs provide superior wind uplift resistance and are suitable for a wider range of building types. Understanding these distinctions helps you select the optimal roofing system based on your building's structural capacity, climate, and maintenance preferences.

Materials Used in Ballasted Roof Assemblies

Ballasted roof assemblies primarily use heavy materials such as river rock or gravel to secure the roofing membrane, resting on a layer of insulation and a waterproof membrane. This ballast technique eliminates the need for mechanical fasteners by relying on the weight of the materials to hold the roof system in place. Your choice of materials affects the roof's durability, drainage, and maintenance requirements compared to mechanically attached systems.

Materials Used in Mechanically Attached Roofing Systems

Mechanically attached roofing systems typically use materials such as thermoplastic polyolefin (TPO), polyvinyl chloride (PVC), and ethylene propylene diene monomer (EPDM) membranes, fastened directly to the roof deck with screws and plates. These durable membranes offer strong resistance to weather, UV rays, and chemicals, providing long-lasting protection for commercial buildings. Your choice of mechanically attached roofing materials ensures a secure, flexible installation suitable for various roof deck types.

Installation Process: Ballasted vs Mechanically Attached Roofs

The installation process of ballasted roofs involves laying heavy materials like gravel or pavers over a membrane to secure it, minimizing penetrations and reducing installation time. Mechanically attached roofs require fastening the membrane directly to the roof deck using screws and plates, providing strong wind resistance but increasing labor and installation complexity. Your choice depends on factors such as roof slope, wind uplift requirements, and ease of future membrane replacement.

Performance and Durability Comparison

Ballasted roofs excel in durability by using heavy materials like gravel or pavers to secure membranes, providing superior resistance against wind uplift and UV damage. Mechanically attached roofs rely on fasteners, which can be more vulnerable to loosening over time, potentially leading to membrane detachment and water infiltration. Performance-wise, ballasted roofs offer enhanced load distribution and thermal insulation, while mechanically attached systems allow easier installation and repairs but may sacrifice long-term resilience.

Wind Resistance and Uplift Considerations

Ballasted roofs rely on the weight of ballast materials, such as gravel or pavers, to resist wind uplift, making them highly effective in areas with moderate wind conditions; however, their performance can be compromised in high-wind zones due to potential displacement of ballast. Mechanically attached roofs use fasteners and plates to secure the membrane directly to the roof deck, offering superior wind resistance and minimizing uplift risk, especially in regions prone to strong winds and storms. Evaluating local wind speeds and building codes is essential for selecting between ballasted and mechanically attached systems to ensure optimal wind uplift protection and long-term durability.

Maintenance Requirements for Both Roofing Systems

Ballasted roofs require periodic inspections to ensure ballast materials remain evenly distributed and free of debris, preventing roof membrane damage or displacement. Mechanically attached roofs demand regular checks of fasteners and seams to detect signs of loosening or corrosion, which can compromise the roof's integrity and cause leaks. Your maintenance plan should reflect these differences to optimize roof performance and longevity.

Cost Analysis: Ballasted vs Mechanically Attached Roofs

Ballasted roofs generally offer lower initial installation costs due to simpler attachment methods and reduced labor requirements compared to mechanically attached roofs, which involve more complex fastening systems and higher labor intensity. However, mechanically attached roofs often provide greater long-term value through enhanced wind resistance and durability, potentially reducing maintenance and replacement expenses over the roof's lifespan. Evaluating total cost of ownership, including installation, maintenance, and lifecycle, is crucial for choosing between ballasted and mechanically attached roofing systems in commercial applications.

Best Applications and Suitability for Each Roofing System

Ballasted roofs are best suited for low-slope commercial buildings with sturdy decks capable of supporting heavy gravel or paver ballast, offering excellent protection against wind uplift and UV exposure. Mechanically attached roofs are ideal for areas with moderate to steep slopes and structures requiring fast installation and easy membrane repairs, providing strong resistance to wind and allowing flexibility for roof movement. Choosing the right system for your building depends on factors like roof pitch, local weather conditions, and structural load capacity.

Ballasted roof vs mechanically attached roof Infographic

libmatt.com

libmatt.com