Screw piles and helical piles both serve as deep foundation solutions designed to support structures, but screw piles are typically used for lighter loads and shallower installations, while helical piles are engineered for heavier loads and deeper soil penetration. Your choice between the two depends on soil conditions, load requirements, and project specifications to ensure optimal foundation stability and performance.

Table of Comparison

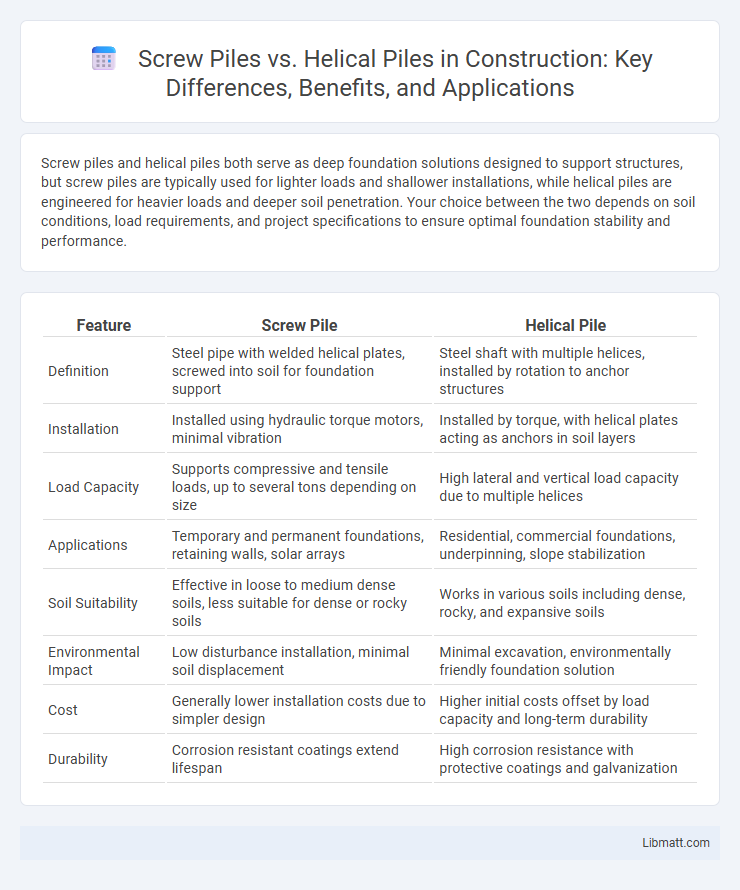

| Feature | Screw Pile | Helical Pile |

|---|---|---|

| Definition | Steel pipe with welded helical plates, screwed into soil for foundation support | Steel shaft with multiple helices, installed by rotation to anchor structures |

| Installation | Installed using hydraulic torque motors, minimal vibration | Installed by torque, with helical plates acting as anchors in soil layers |

| Load Capacity | Supports compressive and tensile loads, up to several tons depending on size | High lateral and vertical load capacity due to multiple helices |

| Applications | Temporary and permanent foundations, retaining walls, solar arrays | Residential, commercial foundations, underpinning, slope stabilization |

| Soil Suitability | Effective in loose to medium dense soils, less suitable for dense or rocky soils | Works in various soils including dense, rocky, and expansive soils |

| Environmental Impact | Low disturbance installation, minimal soil displacement | Minimal excavation, environmentally friendly foundation solution |

| Cost | Generally lower installation costs due to simpler design | Higher initial costs offset by load capacity and long-term durability |

| Durability | Corrosion resistant coatings extend lifespan | High corrosion resistance with protective coatings and galvanization |

Introduction to Screw Piles and Helical Piles

Screw piles and helical piles are deep foundation solutions designed to support structures by transferring loads to stable soil layers. Screw piles consist of a steel shaft with a helical plate that is manually or mechanically driven into the ground, offering rapid installation and minimal soil disturbance. Helical piles, characterized by one or more helical blades welded to a central shaft, provide high load-bearing capacity and are suitable for various soil conditions, including weak or unstable substrates.

What Are Screw Piles?

Screw piles, also known as helical piles, are deep foundation solutions featuring steel shafts with helically shaped plates that anchor into the soil to provide stable support for structures. These piles are installed by rotating them into the ground, enabling quick installation with minimal vibration and disturbance. Your project benefits from their high load-bearing capacity and suitability for a wide range of soil conditions, including soft or unstable ground.

What Are Helical Piles?

Helical piles are deep foundation solutions consisting of a steel shaft with helical plates that anchor securely into the soil, providing superior load-bearing capacity. These piles are installed by rotating them into the ground, minimizing soil disturbance and allowing for quick, efficient foundation support. You can rely on helical piles for stability in challenging soil conditions where traditional foundations may fail.

Key Differences Between Screw and Helical Piles

Screw piles feature a central steel shaft with one or more large flat blades that anchor into the soil, providing high load-bearing capacity and quick installation. Helical piles consist of a steel shaft with multiple helix plates that screw into the ground, offering superior resistance to uplift forces and suitability for varied soil conditions. The primary differences lie in their load distribution methods, installation techniques, and adaptability to soil types, with screw piles typically used for lighter loads and helical piles favored for complex geotechnical challenges.

Installation Process Comparison

Screw piles are installed by rotating the pile into the ground using hydraulic machinery, requiring minimal soil disturbance and allowing for precise depth control. Helical piles, featuring one or more helical plates, are screwed into the soil similarly but often require specific torque monitoring to ensure load capacity and stability. Both methods enable quick installation with limited excavation, but screw piles generally offer faster installation in tighter or more compact soils compared to helical piles.

Load-Bearing Capacity and Performance

Screw piles and helical piles both offer exceptional load-bearing capacity, with helical piles often providing superior lateral and axial load resistance due to their helix plates embedded in soil layers. Performance varies based on soil conditions; helical piles excel in softer or unstable soils by distributing loads effectively, while screw piles are preferred for fast installation in firm substrates. Engineering data shows helical piles can support loads up to 200 kips per pile, making them ideal for heavy structural applications requiring high stability.

Applications in Construction Projects

Screw piles and helical piles offer versatile foundation solutions in construction projects, ideal for supporting structures in challenging soil conditions. Screw piles are often used for light to medium loads in residential buildings, decks, and retaining walls due to their ease of installation and minimal site disturbance. Helical piles excel in commercial and industrial applications requiring deep foundation support, such as bridges and high-rise buildings, because of their high load-bearing capacity and adaptability to various subsurface environments.

Advantages of Screw Piles

Screw piles offer rapid installation with minimal soil disturbance, reducing construction time and environmental impact. Their load-bearing capacity adapts well to diverse soil conditions, providing reliable foundation support for residential and commercial structures. Maintenance costs are low due to corrosion-resistant coatings, ensuring long-term durability and stability under varying weather conditions.

Benefits of Helical Piles

Helical piles offer superior load-bearing capacity and faster installation compared to traditional screw piles, making them ideal for challenging soil conditions and tight project timelines. Their corrosion-resistant coatings extend structural longevity, reducing long-term maintenance costs. You can rely on helical piles for environmentally friendly and minimally invasive foundation solutions.

Choosing the Right Pile for Your Project

Screw piles and helical piles both serve as versatile deep foundation solutions, but their selection depends on soil conditions and load requirements. Screw piles offer quick installation in softer soils with moderate load-bearing needs, while helical piles excel in denser soils and high-load applications due to their multi-helical design. Assessing site-specific factors such as soil type, project load, and environmental impact ensures the optimal pile choice for structural stability and cost-efficiency.

Screw pile vs Helical pile Infographic

libmatt.com

libmatt.com