Sandblasting uses fine abrasive materials to clean or etch surfaces, ideal for delicate or detailed work, while shot blasting propels heavier steel or metal shots at higher speeds for more aggressive surface preparation and rust removal. Your choice depends on the material and finish desired, with sandblasting suited for finer textures and shot blasting for tougher, industrial-grade cleaning.

Table of Comparison

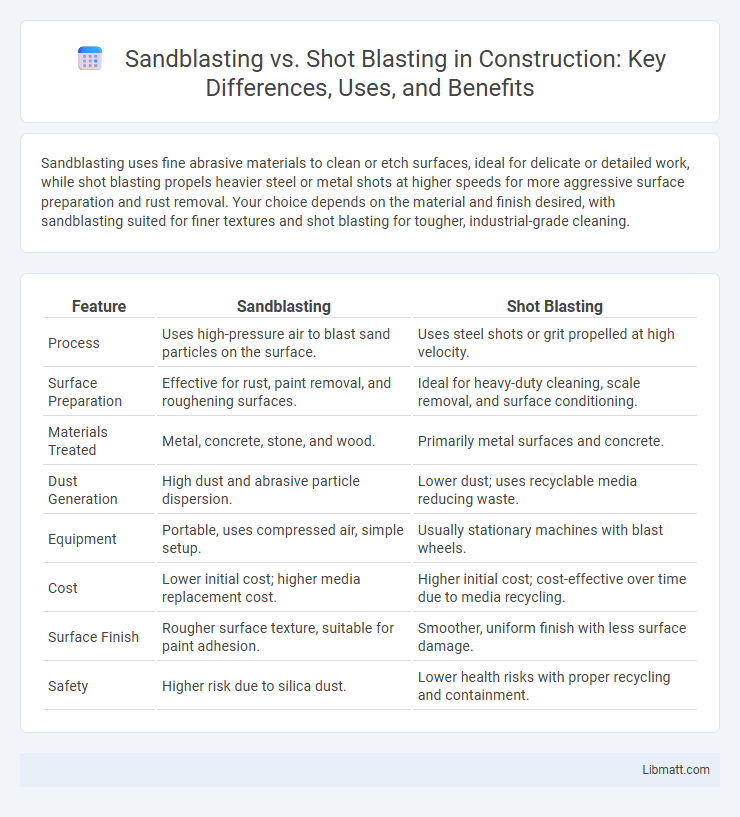

| Feature | Sandblasting | Shot Blasting |

|---|---|---|

| Process | Uses high-pressure air to blast sand particles on the surface. | Uses steel shots or grit propelled at high velocity. |

| Surface Preparation | Effective for rust, paint removal, and roughening surfaces. | Ideal for heavy-duty cleaning, scale removal, and surface conditioning. |

| Materials Treated | Metal, concrete, stone, and wood. | Primarily metal surfaces and concrete. |

| Dust Generation | High dust and abrasive particle dispersion. | Lower dust; uses recyclable media reducing waste. |

| Equipment | Portable, uses compressed air, simple setup. | Usually stationary machines with blast wheels. |

| Cost | Lower initial cost; higher media replacement cost. | Higher initial cost; cost-effective over time due to media recycling. |

| Surface Finish | Rougher surface texture, suitable for paint adhesion. | Smoother, uniform finish with less surface damage. |

| Safety | Higher risk due to silica dust. | Lower health risks with proper recycling and containment. |

Introduction to Surface Preparation Techniques

Sandblasting and shot blasting are critical surface preparation techniques used to clean, smooth, or roughen surfaces before coating or painting. Sandblasting utilizes abrasive materials like sand propelled at high velocity to remove rust, paint, or contaminants, ideal for delicate or irregular surfaces. Shot blasting employs steel or metal pellets to achieve deeper surface cleaning and profiling, making it suitable for heavy-duty industrial applications where surface toughness and texture uniformity are essential.

What is Sandblasting?

Sandblasting is a surface preparation technique that propels fine abrasive particles, typically sand, at high velocity to clean, smooth, or etch surfaces. This process removes rust, paint, scale, and other contaminants from metal, concrete, and wood, enhancing surface texture and adhesion for coatings or treatments. Commonly used in industries like automotive, construction, and manufacturing, sandblasting enables efficient restoration and preparation of various materials.

What is Shot Blasting?

Shot blasting is an industrial process that uses high-velocity steel shots to clean, strengthen, or polish metal surfaces. This technique effectively removes rust, scale, and contaminants while improving surface texture and preparing materials for coating or painting. Shot blasting is widely used in automotive, construction, and manufacturing industries for its efficiency and ability to enhance metal durability.

Key Differences Between Sandblasting and Shot Blasting

Sandblasting uses abrasive materials like sand to clean or etch surfaces, while shot blasting employs steel shots or grit for heavy-duty cleaning and surface preparation. Sandblasting is ideal for detailed, delicate work but generates more dust, whereas shot blasting offers greater efficiency and dust control for larger industrial applications. Your choice depends on the surface type, desired finish, and project scale, with shot blasting often preferred for metal and concrete, and sandblasting suited to precision tasks.

Materials Used in Sandblasting vs Shot Blasting

Sandblasting typically uses abrasive materials like silica sand, garnet, glass beads, or aluminum oxide to clean or etch surfaces, making it ideal for detailed work on softer materials. Shot blasting utilizes metal media such as steel shots or steel grit, which provides more aggressive cleaning and surface preparation on tougher materials like steel or cast iron. Understanding the differences in abrasive media can help you choose the right technique for your specific material and surface treatment needs.

Applications and Industries for Each Method

Sandblasting is widely used in construction, automotive restoration, and marine industries for surface preparation, rust removal, and cleaning intricate details. Shot blasting finds applications in heavy manufacturing, aerospace, and metal fabrication sectors, where it efficiently removes scale, deburrs, and improves metal surfaces for coating adherence. Both methods serve crucial roles in preparing surfaces but differ in material impact and finish quality based on industrial requirements.

Safety Considerations: Sandblasting vs Shot Blasting

Sandblasting involves using abrasive materials like silica sand, which poses significant respiratory hazards due to silica dust, requiring stringent personal protective equipment (PPE) and dust control measures to prevent silicosis. Shot blasting utilizes steel or other metal particles, generating less airborne dust but still demands protective gear against high-velocity particles and noise exposure. Both processes mandate enclosed work areas, ventilation systems, and employee training to minimize injury risks and ensure compliance with occupational safety standards such as OSHA regulations.

Environmental Impact Comparison

Sandblasting generates more dust and abrasive waste, contributing to greater environmental pollution and requiring extensive containment measures. Shot blasting uses steel or abrasive grit that can be recycled, significantly reducing waste and minimizing airborne contaminants. You can reduce your carbon footprint and comply with environmental regulations more effectively by choosing shot blasting over sandblasting.

Cost Analysis and Efficiency

Sandblasting generally incurs lower initial equipment costs, making it more accessible for smaller projects, while shot blasting requires a higher upfront investment but offers greater efficiency for large-scale operations due to faster processing speeds and reusable abrasive media. In terms of operational expenses, shot blasting reduces abrasive consumption and material waste, leading to lower long-term costs compared to sandblasting, which often requires more frequent media replacement. Your choice between the two methods should consider project size, surface preparation requirements, and budget constraints to maximize cost-effectiveness and productivity.

Choosing the Right Blasting Method for Your Project

Selecting the ideal blasting method depends on your project's surface material and desired finish quality. Sandblasting uses abrasive sand particles for effective rust and paint removal on softer surfaces, while shot blasting employs steel beads to clean and strengthen harder metals with minimal surface damage. Understanding these differences ensures your project achieves optimal surface preparation and durability.

Sandblasting vs shot blasting Infographic

libmatt.com

libmatt.com