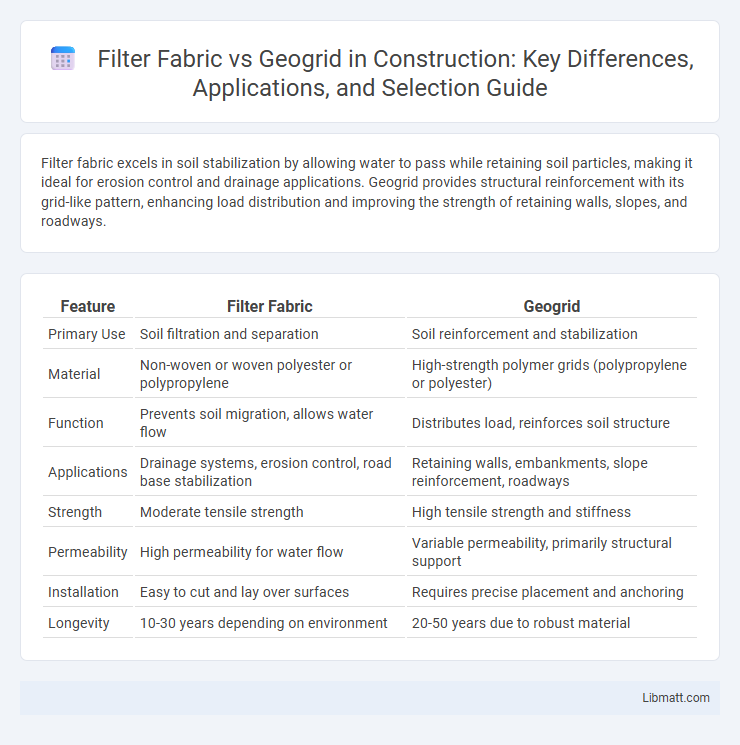

Filter fabric excels in soil stabilization by allowing water to pass while retaining soil particles, making it ideal for erosion control and drainage applications. Geogrid provides structural reinforcement with its grid-like pattern, enhancing load distribution and improving the strength of retaining walls, slopes, and roadways.

Table of Comparison

| Feature | Filter Fabric | Geogrid |

|---|---|---|

| Primary Use | Soil filtration and separation | Soil reinforcement and stabilization |

| Material | Non-woven or woven polyester or polypropylene | High-strength polymer grids (polypropylene or polyester) |

| Function | Prevents soil migration, allows water flow | Distributes load, reinforces soil structure |

| Applications | Drainage systems, erosion control, road base stabilization | Retaining walls, embankments, slope reinforcement, roadways |

| Strength | Moderate tensile strength | High tensile strength and stiffness |

| Permeability | High permeability for water flow | Variable permeability, primarily structural support |

| Installation | Easy to cut and lay over surfaces | Requires precise placement and anchoring |

| Longevity | 10-30 years depending on environment | 20-50 years due to robust material |

Introduction: Understanding Filter Fabric and Geogrid

Filter fabric, also known as geotextile, is a permeable material used primarily for soil filtration and separation in civil engineering projects, preventing soil erosion while allowing water flow. Geogrids are rigid or semi-rigid polymeric materials designed to reinforce soil by distributing loads and enhancing stability in retaining walls, roadways, and embankments. Both materials serve crucial roles in ground improvement but differ significantly in function, structure, and application within geotechnical engineering.

Key Functions: Filtration vs. Reinforcement

Filter fabric excels in filtration by allowing water to pass through while retaining soil particles, preventing erosion and maintaining soil stability. Geogrids provide structural reinforcement by distributing loads and increasing soil strength in applications such as road construction and retaining walls. Both materials serve critical but distinct roles in geotechnical engineering, with filter fabric focusing on filtration and geogrids on reinforcement.

Material Composition and Properties

Filter fabric is typically made from woven or non-woven polypropylene or polyester fibers designed for high permeability and filtration efficiency, allowing water to pass while retaining soil particles. Geogrids, composed primarily of high-strength polymers such as polyester, polyethylene, or polypropylene, provide superior tensile strength and load distribution for soil reinforcement. Your choice should depend on whether filtration or structural support is the primary concern in your project.

Types and Classifications

Filter fabrics, primarily categorized as woven, non-woven, and knitted, serve diverse functions including filtration, separation, and drainage in geotechnical applications. Geogrids, classified by material composition such as polyester, polypropylene, or polyethylene and by structure like uniaxial, biaxial, or triaxial, primarily provide soil reinforcement and stabilization. Each type and classification offers distinct mechanical properties and permeability levels tailored to specific engineering requirements.

Installation Methods and Considerations

Filter fabric installation requires unrolling the material over a prepared surface, ensuring proper overlap of edges to prevent soil intrusion, and anchoring securely with stakes or pins for stability. Geogrid installation involves placing the grid on a leveled base, followed by backfilling with aggregate or soil to lock the grid in place, often necessitating heavy machinery for compaction. Key considerations include soil type compatibility, site conditions, and adherence to manufacturer guidelines for both materials to maximize performance and longevity.

Performance in Soil Stabilization

Filter fabric excels in soil stabilization by allowing water to pass while retaining fine particles, reducing erosion and improving soil structure. Geogrids provide superior reinforcement through high tensile strength, distributing loads and preventing soil displacement under heavy pressure. Your choice depends on the specific project needs, with filter fabric optimizing filtration and geogrids enhancing load-bearing capacity.

Applications: Where to Use Filter Fabric vs. Geogrid

Filter fabric is ideal for soil stabilization and drainage in applications such as road construction, retaining walls, and erosion control, where it prevents soil migration while allowing water flow. Geogrids are best suited for reinforcing weak soils in heavy load-bearing applications like embankments, retaining walls, and highway subbases, providing tensile strength to improve overall stability. Your choice depends on whether you need filtration and separation or structural reinforcement in your project.

Cost Comparison and Economic Factors

Filter fabric generally costs less per square meter compared to geogrids, making it a more budget-friendly option for erosion control and soil stabilization projects. Geogrids, while more expensive initially, provide superior load distribution and long-term durability that can reduce maintenance and repair expenses. Considering lifecycle costs, the higher upfront investment in geogrids often leads to better economic value in heavy-load or high-traffic applications.

Longevity and Durability

Filter fabric and geogrids differ significantly in longevity and durability, with geogrids typically offering higher tensile strength and resistance to deformation under load, making them suitable for long-term stabilization projects. Filter fabrics provide effective filtration and separation but may degrade faster when exposed to UV rays and chemical contaminants, reducing their lifespan in harsh environments. Selecting the appropriate material depends on project requirements, soil conditions, and environmental exposure to ensure maximum durability and performance.

Choosing the Right Solution for Your Project

Filter fabric excels in soil filtration and drainage, preventing soil migration while allowing water flow, making it ideal for erosion control and sediment retention. Geogrids provide superior reinforcement and load distribution in retaining walls, roadways, and pavements due to their tensile strength and grid structure. Selecting between filter fabric and geogrid depends on project-specific requirements such as soil stability, drainage needs, and structural support objectives.

Filter fabric vs geogrid Infographic

libmatt.com

libmatt.com