Bituminous membranes provide a durable, flexible waterproof barrier commonly used on roofs, offering strong resistance to UV radiation and weathering, while liquid membranes form a seamless, self-healing coating that adapts to complex shapes and penetrates cracks for comprehensive protection. You can choose bituminous membranes for heavy-duty, long-lasting applications or liquid membranes for easy application and superior adhesion on irregular surfaces.

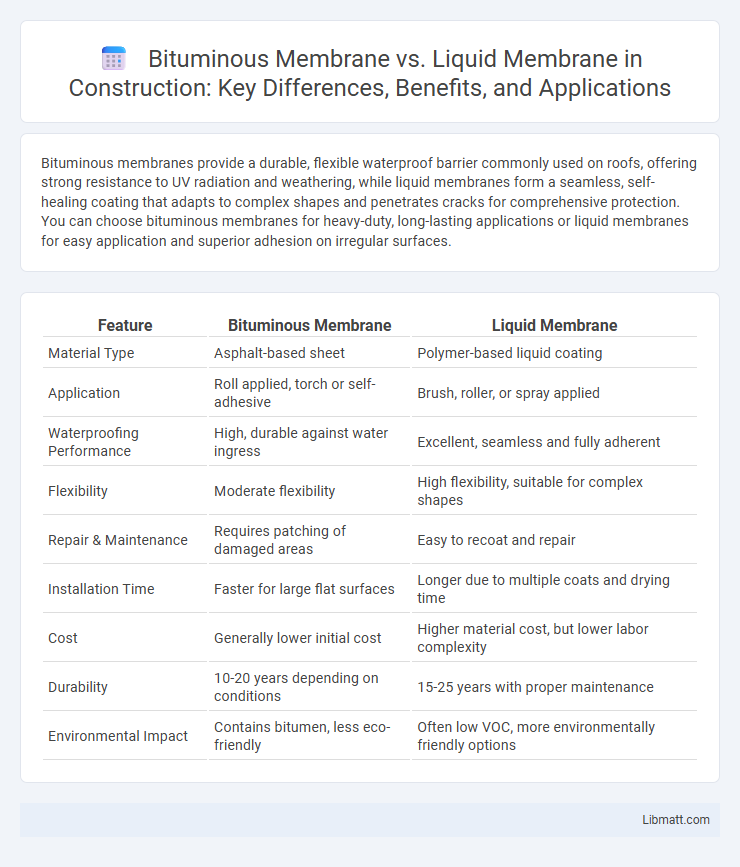

Table of Comparison

| Feature | Bituminous Membrane | Liquid Membrane |

|---|---|---|

| Material Type | Asphalt-based sheet | Polymer-based liquid coating |

| Application | Roll applied, torch or self-adhesive | Brush, roller, or spray applied |

| Waterproofing Performance | High, durable against water ingress | Excellent, seamless and fully adherent |

| Flexibility | Moderate flexibility | High flexibility, suitable for complex shapes |

| Repair & Maintenance | Requires patching of damaged areas | Easy to recoat and repair |

| Installation Time | Faster for large flat surfaces | Longer due to multiple coats and drying time |

| Cost | Generally lower initial cost | Higher material cost, but lower labor complexity |

| Durability | 10-20 years depending on conditions | 15-25 years with proper maintenance |

| Environmental Impact | Contains bitumen, less eco-friendly | Often low VOC, more environmentally friendly options |

Introduction to Waterproofing Membranes

Bituminous membranes are widely used in waterproofing due to their durability, flexibility, and strong adhesion, making them suitable for roofs and foundations. Liquid membranes, applied as a seamless coating, offer excellent adaptability to complex shapes and surfaces, providing a continuous barrier against water ingress. Both types enhance structural protection by preventing moisture penetration, but choice depends on the project's specific requirements and environmental conditions.

Overview of Bituminous Membranes

Bituminous membranes are waterproofing products made from asphalt-based materials reinforced with polyester or fiberglass mats, offering excellent durability and resistance to water infiltration. Commonly used in roofing and foundation applications, these membranes provide high tensile strength, flexibility, and UV protection, making them suitable for harsh environmental conditions. Their ease of installation, via torch-on or self-adhesive methods, combined with long-term performance, distinguishes bituminous membranes from liquid membranes in durability and application versatility.

Overview of Liquid Membranes

Liquid membranes provide a seamless, flexible waterproofing solution by forming a continuous barrier when applied, unlike the rigid structure of bituminous membranes. Their ease of application allows for efficient coverage on complex surfaces, enhancing durability and resistance to water infiltration. You can expect improved adhesion and chemical resistance, making liquid membranes ideal for varied construction and roofing projects.

Material Composition and Properties Comparison

Bituminous membranes consist mainly of bitumen combined with reinforcing fabrics like fiberglass or polyester, offering excellent waterproofing, UV resistance, and durability for roofing applications. Liquid membranes are composed of polyurethane, acrylic, or elastomeric polymers, creating seamless, flexible, and highly elastic coatings suitable for complex shapes and areas requiring crack-bridging capabilities. While bituminous membranes provide robust mechanical strength and heat resistance, liquid membranes excel in adhesion, adaptability, and ease of application on irregular surfaces.

Application Methods: Bituminous vs Liquid Membranes

Bituminous membranes are typically applied using heat or self-adhesive techniques, requiring specialized equipment like torches or rollers to ensure proper adhesion and layering. Liquid membranes are applied by brushing, rolling, or spraying directly onto surfaces, allowing for seamless coverage and easy adaptation to complex shapes and details. Your choice depends on project complexity, surface type, and required flexibility, with liquid membranes offering greater ease of application and bituminous membranes providing strong, durable protection.

Durability and Longevity Analysis

Bituminous membranes offer superior durability due to their high resistance to water, UV rays, and temperature fluctuations, ensuring a lifespan of up to 25 years when properly installed. Liquid membranes provide seamless application that adapts to complex surfaces, but their longevity typically ranges between 10 to 15 years, with performance heavily dependent on the quality of the application and environmental conditions. The choice between the two depends on project requirements for long-term protection and maintenance frequency.

Performance in Different Climates

Bituminous membranes provide excellent waterproofing and durability in hot, dry climates with their high resistance to UV radiation and thermal shock, while liquid membranes offer superior flexibility and seamless coverage ideal for cold or complex surfaces. Liquid membranes adapt well to temperature fluctuations, reducing the risk of cracks in freezing conditions, whereas bituminous membranes can become brittle in extreme cold. Your choice depends on climate-specific performance needs, ensuring long-lasting protection for your structure.

Cost Effectiveness and Maintenance

Bituminous membranes generally offer lower initial costs compared to liquid membranes, making them a cost-effective option for budget-conscious projects. Maintenance for bituminous membranes typically involves periodic inspections and repairs to address potential cracks or tears, whereas liquid membranes provide seamless waterproofing with easier spot repairs, reducing long-term maintenance expenses. You can optimize your investment by considering the durability and maintenance requirements of each membrane type relative to your specific application.

Environmental Impact and Sustainability

Bituminous membranes often contain petroleum-derived components that can release harmful volatile organic compounds (VOCs) during application, posing environmental concerns. Liquid membranes typically utilize water-based or bio-based formulas with lower VOC emissions, enhancing sustainability and reducing ecological impact. Choosing liquid membranes can improve your project's environmental footprint by supporting eco-friendly material use and easier recyclability.

Choosing the Right Membrane for Your Project

Bituminous membranes provide excellent waterproofing with proven durability, ideal for flat roofs and foundations requiring robust protection against water penetration. Liquid membranes offer seamless application and superior flexibility, making them suitable for complex shapes and areas prone to movement or cracking. Evaluating project-specific factors such as surface type, climate conditions, and exposure to UV radiation ensures selecting the most effective membrane solution.

Bituminous membrane vs Liquid membrane Infographic

libmatt.com

libmatt.com