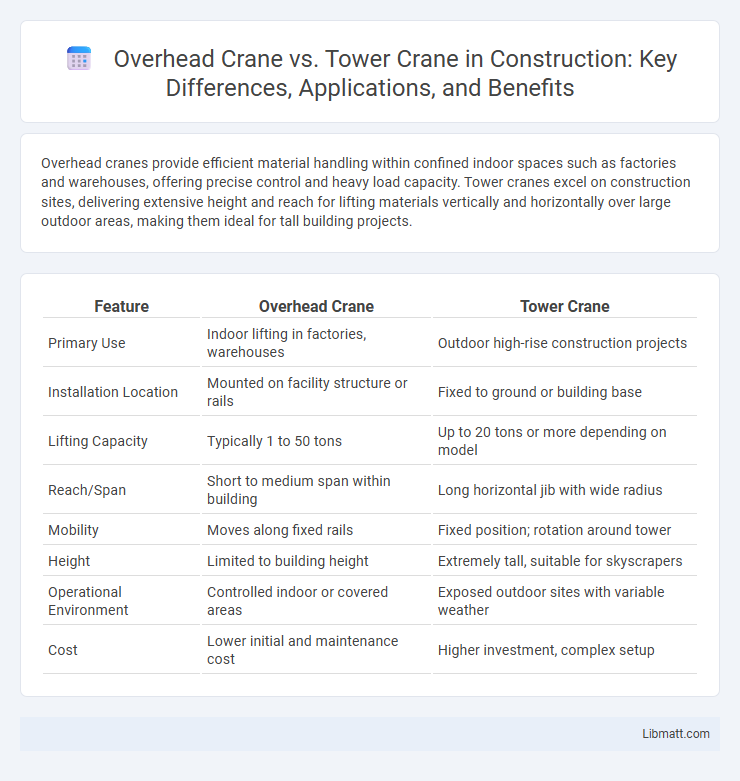

Overhead cranes provide efficient material handling within confined indoor spaces such as factories and warehouses, offering precise control and heavy load capacity. Tower cranes excel on construction sites, delivering extensive height and reach for lifting materials vertically and horizontally over large outdoor areas, making them ideal for tall building projects.

Table of Comparison

| Feature | Overhead Crane | Tower Crane |

|---|---|---|

| Primary Use | Indoor lifting in factories, warehouses | Outdoor high-rise construction projects |

| Installation Location | Mounted on facility structure or rails | Fixed to ground or building base |

| Lifting Capacity | Typically 1 to 50 tons | Up to 20 tons or more depending on model |

| Reach/Span | Short to medium span within building | Long horizontal jib with wide radius |

| Mobility | Moves along fixed rails | Fixed position; rotation around tower |

| Height | Limited to building height | Extremely tall, suitable for skyscrapers |

| Operational Environment | Controlled indoor or covered areas | Exposed outdoor sites with variable weather |

| Cost | Lower initial and maintenance cost | Higher investment, complex setup |

Introduction to Overhead and Tower Cranes

Overhead cranes, also known as bridge cranes, are designed for heavy lifting in industrial environments, featuring a fixed horizontal beam and a hoist that moves along the beam. Tower cranes are tall, fixed structures commonly used in construction sites to lift heavy materials vertically and horizontally with a long jib arm. Your choice between these cranes depends on the operational environment, load capacity, and spatial constraints.

Key Differences Between Overhead and Tower Cranes

Overhead cranes feature horizontal beams supported by end trucks that move along elevated runways, ideal for lifting heavy loads within confined industrial spaces, while tower cranes are tall, fixed structures designed for vertical and horizontal lifting on construction sites, capable of reaching great heights. The key differences between overhead and tower cranes lie in their mobility, load capacity, and application environments: overhead cranes excel in controlled indoor settings with precise, heavy-duty handling, whereas tower cranes offer extensive reach and height for outdoor construction projects. Understanding these distinctions helps you select the appropriate crane type for your specific lifting needs, maximizing efficiency and safety.

Typical Applications: Where Each Crane Excels

Overhead cranes excel in indoor environments such as manufacturing plants, warehouses, and assembly lines where precise, repetitive lifting of heavy materials is required. Tower cranes are ideal for large-scale construction sites, especially in urban areas, where they provide significant height and reach to lift heavy loads like steel beams and concrete panels. Overhead cranes offer superior load control in confined spaces, while tower cranes enable vertical and horizontal transport of materials across expansive outdoor areas.

Load Capacity Comparison

Overhead cranes typically offer load capacities ranging from a few tons up to 50 tons, making them ideal for indoor material handling in manufacturing and warehouses. Tower cranes support much heavier loads, often exceeding 20 tons and reaching up to 80 tons or more, designed for large-scale construction projects involving tall structures. Understanding the load capacity differences helps you select the appropriate crane type to safely and efficiently meet your project's lifting requirements.

Installation and Setup Requirements

Overhead cranes require precise alignment and secure mounting on robust runway beams or structures, often demanding substantial preparation of the building's infrastructure before installation. Tower cranes need a stable concrete foundation and careful assembly of modular sections using mobile cranes, with setup complexity increasing based on crane height and load capacity. Both types demand specialized labor and safety measures to ensure structural integrity and operational reliability during use.

Space and Site Considerations

Overhead cranes require a fixed runway system, limiting their use to confined industrial spaces with predetermined paths, making them ideal for indoor environments or areas with limited horizontal space. Tower cranes, on the other hand, maximize vertical space utilization and are best suited for large construction sites with ample open areas and significant height requirements. Your choice depends on site layout and space availability, as overhead cranes save floor space while tower cranes offer extended reach and height flexibility.

Operating Mechanisms and Controls

Overhead cranes operate using horizontal beams mounted on elevated runways, controlled by motorized trolleys that move loads along the beam and across spans, providing precise linear movement ideal for indoor environments. Tower cranes feature a vertical mast with a slewing jib that rotates 360 degrees, employing hoisting winches and sophisticated operator cabins with joystick controls to manage load lifting and positioning at various heights on construction sites. The control systems of overhead cranes typically involve remote control or pendant operations, while tower cranes rely on advanced electronic controls and onboard computers to ensure stability and safe load handling at extended reaches.

Safety Features and Risks

Overhead cranes feature enclosed rails and controlled lifting paths that minimize collision risks within industrial settings, while tower cranes operate at significant heights requiring strict wind and load monitoring to prevent structural failure. Overhead cranes incorporate limit switches, emergency stop buttons, and overload protection systems to ensure precise load handling, contrasting with tower cranes that rely heavily on robust anchoring systems and operator training to mitigate fall hazards. Both crane types face risks of mechanical failure and human error but differ in environmental exposure, with tower cranes demanding heightened safety protocols due to their elevated work environment and public proximity.

Cost Analysis: Purchase, Operation, and Maintenance

Overhead cranes typically have lower purchase costs compared to tower cranes due to simpler structural requirements and smaller size. Operational expenses for overhead cranes are reduced by their energy efficiency and ease of integration within factory settings, while tower cranes incur higher costs driven by their large scale and complex setup. Maintenance costs for overhead cranes are generally minimal, focusing on mechanical and electrical checks, whereas tower cranes demand frequent, specialized inspections and substantial upkeep due to exposure to harsh weather conditions and intense load cycles.

Choosing the Right Crane for Your Project

Choosing the right crane for your project depends on factors such as load capacity, site layout, and height requirements. Overhead cranes excel in indoor environments with fixed rails, providing precise material handling for manufacturing or warehouse settings. Tower cranes offer superior height and reach for tall building construction but require more space and setup time.

Overhead crane vs tower crane Infographic

libmatt.com

libmatt.com