A bull float is a large, heavy tool typically made of aluminum or magnesium used to smooth freshly poured concrete, providing a flat and even surface. Your choice between a bull float and a magnesium float depends on the project size and finish quality, with magnesium floats offering lighter weight and better performance on smaller or detailed areas.

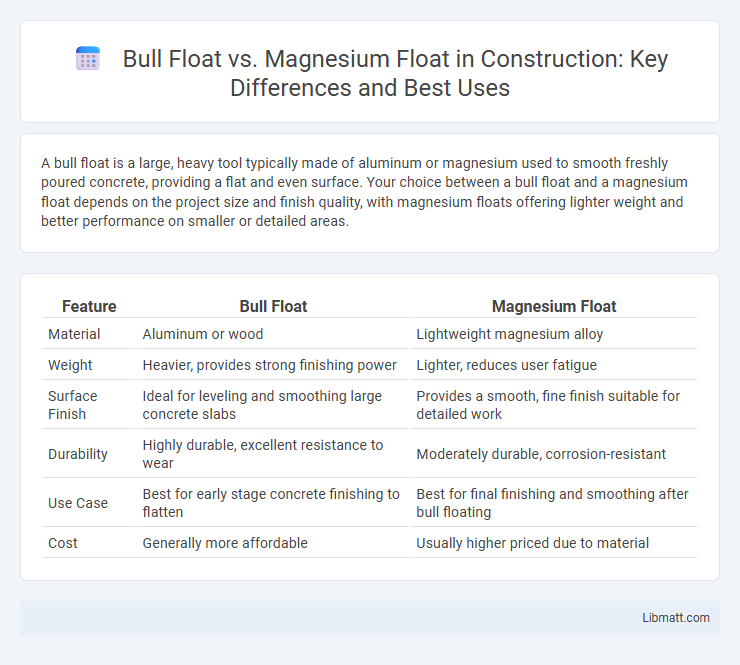

Table of Comparison

| Feature | Bull Float | Magnesium Float |

|---|---|---|

| Material | Aluminum or wood | Lightweight magnesium alloy |

| Weight | Heavier, provides strong finishing power | Lighter, reduces user fatigue |

| Surface Finish | Ideal for leveling and smoothing large concrete slabs | Provides a smooth, fine finish suitable for detailed work |

| Durability | Highly durable, excellent resistance to wear | Moderately durable, corrosion-resistant |

| Use Case | Best for early stage concrete finishing to flatten | Best for final finishing and smoothing after bull floating |

| Cost | Generally more affordable | Usually higher priced due to material |

Introduction to Concrete Floats

Concrete floats are essential tools in finishing freshly poured concrete surfaces, helping to create a smooth, durable finish by leveling and compacting the material. Bull floats, typically made of aluminum or magnesium, feature a long handle and a wide, flat blade for covering large areas efficiently, while magnesium floats are lighter and better suited for detailed work and smaller surfaces. Choosing between a bull float and a magnesium float depends on the project size and desired finish, with magnesium floats providing enhanced control for a fine texture.

What is a Bull Float?

A bull float is a large, flat tool made typically of aluminum or magnesium, designed for smoothing and leveling freshly poured concrete surfaces. It features a long handle that allows you to reach and finish expansive slabs without stepping on the wet concrete. The bull float helps eliminate imperfections, embeds aggregate, and creates a uniform texture essential for strong, durable concrete flooring.

What is a Magnesium Float?

A magnesium float is a lightweight tool used in concrete finishing, featuring a flat magnesium blade that helps smooth and level freshly poured concrete surfaces. Its corrosion-resistant properties make it ideal for use in wet environments, while its light weight reduces operator fatigue during extended use. Compared to a traditional bull float, which is typically larger and heavier, a magnesium float offers greater maneuverability and is best suited for smaller or detailed concrete finishing tasks.

Key Differences Between Bull Float and Magnesium Float

Bull floats are typically larger with a flat aluminum or wood surface used for smoothing concrete over wide areas, while magnesium floats are smaller, lighter, and designed for detailed finishing work on fresh concrete. Magnesium floats offer better resistance to corrosion and provide a smoother finish, making them ideal for finishing edges and tight spaces. Your choice depends on project size and detail requirements, with bull floats suited for initial smoothing and magnesium floats for precision finishing.

Purpose and Applications of Bull Float

Bull floats are primarily used to smooth and level freshly poured concrete surfaces, ensuring a uniform finish by pushing down aggregate and filling small voids. They are ideal for large slabs and expansive concrete areas such as driveways, patios, and sidewalks. Made from lightweight aluminum or magnesium, bull floats enable efficient surface finishing before the concrete fully sets.

Purpose and Applications of Magnesium Float

Magnesium floats are designed for finishing concrete surfaces, offering a lightweight alternative to traditional bull floats, which simplifies handling on large slabs and reduces operator fatigue. Their corrosion-resistant properties and durability make them ideal for smoothing and leveling fresh concrete in both residential and commercial construction projects. Magnesium floats excel in creating flat, uniform finishes on sidewalks, driveways, and floors where precision and efficiency are critical.

Advantages of Using a Bull Float

A bull float provides superior control and smoothness when finishing large concrete surfaces, reducing the appearance of ridges and imperfections. Its long handle allows you to reach distant areas without leaving marks, making it ideal for expansive slabs and driveways. Using a bull float enhances the overall quality and durability of your concrete finish, ensuring professional results.

Benefits of Using a Magnesium Float

Using a magnesium float provides superior durability and lightweight handling compared to traditional bull floats, making it easier to smooth large concrete surfaces with less fatigue. Its resistance to rust and impact ensures long-lasting performance, ideal for both professional contractors and DIY enthusiasts. You'll achieve a finer finish on fresh concrete, enhancing overall surface quality and reducing the need for additional correction.

Choosing the Right Float for Your Project

Choosing the right float for your project depends on the surface finish and material. Bull floats, typically made of aluminum or magnesium with a wide, flat surface, are ideal for smoothing large concrete slabs quickly, while magnesium floats offer a lighter option with better control for detailed finishing and minimizing surface imperfections. Understanding your project's scale and desired texture ensures you select the float that improves concrete durability and appearance effectively.

Bull Float vs Magnesium Float: Final Comparison

A bull float, typically made of aluminum or magnesium, provides a larger surface area ideal for smoothing freshly poured concrete efficiently, while a magnesium float offers superior durability and lighter weight for easier handling in tight spaces. Magnesium floats resist rust and heat better, making them suitable for hot or wet conditions, whereas bull floats excel in covering broad surfaces quickly due to their extended reach and size. Choosing between the two depends on project scale, work environment, and the specific finishing requirements of the concrete surface.

Bull float vs magnesium float Infographic

libmatt.com

libmatt.com