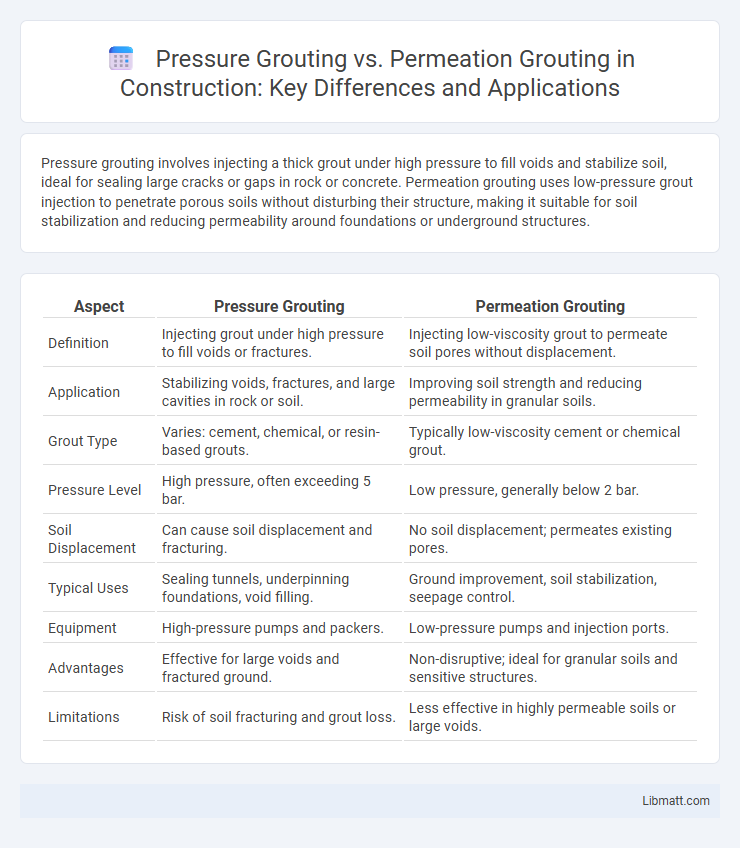

Pressure grouting involves injecting a thick grout under high pressure to fill voids and stabilize soil, ideal for sealing large cracks or gaps in rock or concrete. Permeation grouting uses low-pressure grout injection to penetrate porous soils without disturbing their structure, making it suitable for soil stabilization and reducing permeability around foundations or underground structures.

Table of Comparison

| Aspect | Pressure Grouting | Permeation Grouting |

|---|---|---|

| Definition | Injecting grout under high pressure to fill voids or fractures. | Injecting low-viscosity grout to permeate soil pores without displacement. |

| Application | Stabilizing voids, fractures, and large cavities in rock or soil. | Improving soil strength and reducing permeability in granular soils. |

| Grout Type | Varies: cement, chemical, or resin-based grouts. | Typically low-viscosity cement or chemical grout. |

| Pressure Level | High pressure, often exceeding 5 bar. | Low pressure, generally below 2 bar. |

| Soil Displacement | Can cause soil displacement and fracturing. | No soil displacement; permeates existing pores. |

| Typical Uses | Sealing tunnels, underpinning foundations, void filling. | Ground improvement, soil stabilization, seepage control. |

| Equipment | High-pressure pumps and packers. | Low-pressure pumps and injection ports. |

| Advantages | Effective for large voids and fractured ground. | Non-disruptive; ideal for granular soils and sensitive structures. |

| Limitations | Risk of soil fracturing and grout loss. | Less effective in highly permeable soils or large voids. |

Introduction to Pressure Grouting and Permeation Grouting

Pressure grouting involves injecting a high-viscosity grout under pressure to fill voids and consolidate soil or rock for structural support and increased stability. Permeation grouting uses low-viscosity grout that penetrates soil pores without disturbing existing ground conditions, ideal for reducing permeability and strengthening granular soils. Your choice depends on project requirements such as soil type, desired strength improvement, and environmental impact.

Fundamental Principles of Grouting Techniques

Pressure grouting involves injecting a high-viscosity grout under pressure to fill voids and stabilize soil by displacing existing materials, creating a solidified mass. Permeation grouting uses low-pressure injection of low-viscosity grout to penetrate the pores of soil or cracks without disturbing the soil structure, enhancing its strength and reducing permeability. Your choice between these grouting techniques depends on ground conditions and project requirements for soil stabilization or seepage control.

Key Differences Between Pressure Grouting and Permeation Grouting

Pressure grouting involves injecting a thick, cementitious or chemical grout under pressure to fill cracks, voids, and cavities, effectively stabilizing soil or rock. Permeation grouting uses low-pressure injection of fluid, low-viscosity grout that permeates the soil pores without disturbing the soil fabric, enhancing soil strength and impermeability. The key differences lie in grout consistency, injection pressure, and application purpose: pressure grouting creates a continuous, solid mass, while permeation grouting reinforces soil through pore filling.

Materials Used in Pressure vs. Permeation Grouting

Pressure grouting typically utilizes cement-based materials such as neat cement, microfine cement, and chemical grouts like sodium silicate, ensuring rapid strength gain and effective void filling under high pressure. Permeation grouting employs low-viscosity chemical grouts such as polyurethane, acrylate, or silicate solutions, designed to permeate soil pore spaces without disturbing the soil structure. The choice of materials directly impacts the grouting method's effectiveness based on soil permeability and desired ground improvement outcomes.

Suitable Applications for Each Grouting Method

Pressure grouting is suitable for applications requiring high-strength foundations, soil stabilization beneath heavy structures, and filling large voids or fractures in rock masses. Permeation grouting excels in improving soil permeability and strength in granular soils without disturbing existing structures, making it ideal for soil seepage control, foundation underpinning, and void filling in sandy or silty soils. Selecting the appropriate method depends on soil type, required strength, and project constraints such as environmental impact and structural sensitivity.

Advantages of Pressure Grouting

Pressure grouting offers superior soil stabilization by injecting grout under high pressure, effectively filling voids and fractures in dense or coarse-grained soils where permeation grouting may struggle. This method provides rapid strength gain and excellent load-bearing capacity, making it ideal for underpinning foundations and controlling settlements. Your project benefits from enhanced control over grout distribution and improved structural integrity in challenging ground conditions through pressure grouting.

Advantages of Permeation Grouting

Permeation grouting offers the advantage of minimal ground disturbance by injecting grout into soil pores without altering the soil's structure, making it ideal for sensitive or urban environments. It enhances soil permeability and strength uniformly, reducing the risk of fractures and excessive pressure buildup compared to pressure grouting. This method provides precise control over grout placement, resulting in predictable improvements in soil stability and reduced environmental impact.

Limitations and Challenges of Pressure and Permeation Grouting

Pressure grouting faces limitations such as the potential for soil displacement, fracturing, and uneven grout distribution, which can lead to structural damage or inefficient stabilization. Permeation grouting challenges include the restriction to granular soils with sufficient permeability and the difficulty in controlling grout propagation at fine pore sizes, impacting uniformity and effectiveness. Your choice between these methods must consider soil conditions, project scale, and potential environmental impacts to optimize ground improvement results.

Safety Considerations and Best Practices

Pressure grouting involves injecting grout under high pressure, requiring thorough safety measures to prevent equipment failure and unintended ground displacement, making the use of pressure relief valves and proper monitoring essential. Permeation grouting operates at lower pressures and is generally safer for delicate structures, but it demands meticulous control to avoid clogging and ensure uniform soil stabilization. Ensuring your team follows industry standards and conducts comprehensive site assessments is critical for mitigating risks and achieving successful ground improvement.

Choosing the Right Grouting Method for Your Project

Choosing the right grouting method depends on soil conditions and project goals; pressure grouting is ideal for filling large voids and stabilizing loose soils through high-pressure injection, while permeation grouting suits fine soils by allowing low-pressure grout to penetrate without disturbing the ground. Your project's structural requirements and soil permeability should guide the selection to ensure optimal ground improvement and cost efficiency. Accurate site assessment and material compatibility are critical for achieving durable and uniform soil stabilization.

Pressure grouting vs permeation grouting Infographic

libmatt.com

libmatt.com