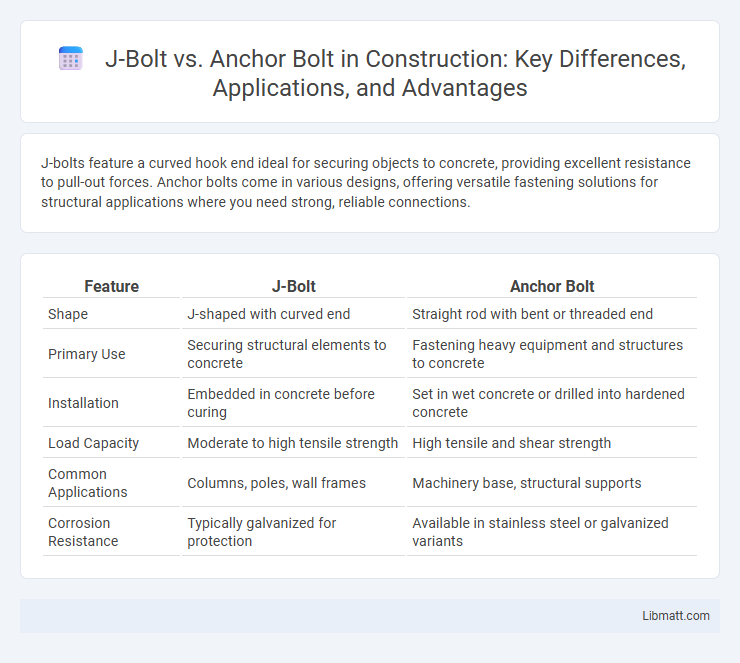

J-bolts feature a curved hook end ideal for securing objects to concrete, providing excellent resistance to pull-out forces. Anchor bolts come in various designs, offering versatile fastening solutions for structural applications where you need strong, reliable connections.

Table of Comparison

| Feature | J-Bolt | Anchor Bolt |

|---|---|---|

| Shape | J-shaped with curved end | Straight rod with bent or threaded end |

| Primary Use | Securing structural elements to concrete | Fastening heavy equipment and structures to concrete |

| Installation | Embedded in concrete before curing | Set in wet concrete or drilled into hardened concrete |

| Load Capacity | Moderate to high tensile strength | High tensile and shear strength |

| Common Applications | Columns, poles, wall frames | Machinery base, structural supports |

| Corrosion Resistance | Typically galvanized for protection | Available in stainless steel or galvanized variants |

Introduction to J-Bolts and Anchor Bolts

J-bolts and anchor bolts serve as essential fasteners in construction, providing secure connections between structural elements and concrete. J-bolts feature a distinctive J-shaped hook designed to embed into concrete, ensuring strong tension resistance for anchoring purposes. Anchor bolts encompass various styles, including expansion anchors and wedge anchors, tailored for fastening objects to concrete or masonry with high shear and pull-out strength.

Definition and Basic Differences

J-bolts are L-shaped fasteners with a curved hook at one end, designed primarily for securing structural elements to concrete. Anchor bolts are straight or bent anchors embedded in concrete to provide a secure connection between structural components and the foundation. The main difference lies in their shape and application: J-bolts are used for hanging or securing items with their hooked end, while anchor bolts provide heavy-duty anchoring with a straight or bent shaft.

Materials and Manufacturing Process

J-bolts and anchor bolts are commonly made from carbon steel, stainless steel, or galvanized steel to ensure strength and corrosion resistance. J-bolts are manufactured by bending a threaded rod into a "J" shape, while anchor bolts often feature a straight rod with a hooked or bent end and may include additional fabrication techniques such as forging or heat treatment for enhanced durability. Both types undergo rigorous quality control processes including threading precision and coating applications to withstand structural loads and environmental conditions.

Common Applications

J-bolts are commonly used for securing structural components to concrete foundations, such as supporting steel columns, light poles, and machinery bases. Anchor bolts are versatile in industrial infrastructure, often employed to fasten heavy equipment, machinery, and base plates to concrete surfaces. Both types provide critical stability in construction, but J-bolts are favored for embedded applications, while anchor bolts excel in adjustable and custom mounting scenarios.

Load Capacity and Strength Comparison

J-bolts typically provide moderate load capacity suitable for light to medium structural applications, while anchor bolts offer higher strength designed for heavy-duty structural loads and seismic resistance. Anchor bolts are engineered with higher tensile strength and greater embedment depth, ensuring superior performance under dynamic and shear stresses. Choosing the right bolt ensures your construction project maintains optimal load-bearing capacity and structural integrity.

Installation Methods

J-bolt installation involves embedding the hooked end into concrete before it sets, providing secure anchorage once hardened. Anchor bolts require drilling holes into cured concrete, followed by insertion and tightening with nuts and washers for a firm hold. Both methods ensure structural stability but differ in timing and surface preparation requirements.

Pros and Cons of J-Bolts

J-bolts offer excellent holding power in concrete, making them ideal for securing structures like steel columns and light poles, but their fixed shape can limit flexibility during installation. These bolts provide strong resistance against shear forces and are easier to install in precast concrete compared to anchor bolts, which require precise drilling and epoxy application. Your choice depends on project requirements, as J-bolts excel in durability but may be less adaptable than the versatile anchor bolts designed for various load conditions.

Pros and Cons of Anchor Bolts

Anchor bolts provide superior holding power for securing structural elements to concrete, making them ideal for heavy-duty applications such as foundations and industrial equipment. Their installation allows for precise positioning before concrete sets, ensuring long-term stability and resistance to shear and tensile forces. However, anchor bolts require accurate placement during the pouring process, can be time-consuming to install, and may be less flexible for adjustments compared to J-bolts, which can be easier to retrofit or adjust on-site.

Factors to Consider When Choosing

When choosing between J-bolts and anchor bolts, consider factors such as load capacity, corrosion resistance, and installation requirements to ensure structural stability. J-bolts typically offer superior grip in concrete foundations due to their curved end design, while anchor bolts provide versatile and easier installation options for various materials. Your decision should align with the specific environmental conditions and mechanical stresses of the project for optimal performance.

Conclusion: Which Bolt is Right for Your Project?

Choosing between a J-bolt and an anchor bolt depends on your project's specific load requirements and installation conditions. J-bolts offer superior resistance to tension forces and are ideal for securing structural elements with a hooked end, while anchor bolts provide versatility in various construction settings with their straight or bent designs. Assess your structural needs and environmental factors to determine which bolt ensures optimal stability and safety for your project.

J-bolt vs anchor bolt Infographic

libmatt.com

libmatt.com