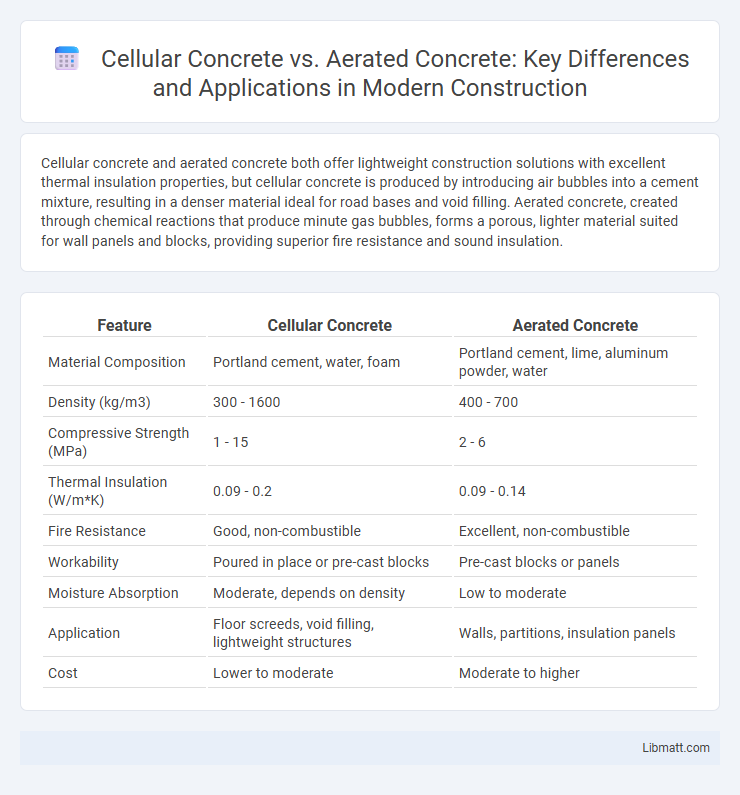

Cellular concrete and aerated concrete both offer lightweight construction solutions with excellent thermal insulation properties, but cellular concrete is produced by introducing air bubbles into a cement mixture, resulting in a denser material ideal for road bases and void filling. Aerated concrete, created through chemical reactions that produce minute gas bubbles, forms a porous, lighter material suited for wall panels and blocks, providing superior fire resistance and sound insulation.

Table of Comparison

| Feature | Cellular Concrete | Aerated Concrete |

|---|---|---|

| Material Composition | Portland cement, water, foam | Portland cement, lime, aluminum powder, water |

| Density (kg/m3) | 300 - 1600 | 400 - 700 |

| Compressive Strength (MPa) | 1 - 15 | 2 - 6 |

| Thermal Insulation (W/m*K) | 0.09 - 0.2 | 0.09 - 0.14 |

| Fire Resistance | Good, non-combustible | Excellent, non-combustible |

| Workability | Poured in place or pre-cast blocks | Pre-cast blocks or panels |

| Moisture Absorption | Moderate, depends on density | Low to moderate |

| Application | Floor screeds, void filling, lightweight structures | Walls, partitions, insulation panels |

| Cost | Lower to moderate | Moderate to higher |

Introduction to Cellular Concrete and Aerated Concrete

Cellular concrete and aerated concrete are lightweight building materials known for their enhanced insulation and fire resistance properties. Cellular concrete is produced by introducing air bubbles into a cement slurry, resulting in a dense, yet porous structure, while aerated concrete incorporates a chemical agent like aluminum powder to create microscopic air pockets during curing. Your choice between these materials depends on project requirements for strength, thermal insulation, and ease of installation.

Composition and Material Differences

Cellular concrete consists of cement, water, and pre-formed foam, creating a lightweight mixture with uniform air voids, whereas aerated concrete incorporates aluminum powder or paste that reacts chemically to produce hydrogen gas bubbles within the cement matrix. Cellular concrete's foam is physically introduced, resulting in controlled pore size and distribution, while aerated concrete's gas expansion occurs in-situ during setting, affecting porosity and strength properties. The distinct methods of pore formation significantly influence thermal insulation, density, and structural characteristics of each material.

Manufacturing Processes Compared

Cellular concrete is produced by introducing pre-formed foam into a cement slurry, creating a lightweight material with uniform air voids. Aerated concrete, on the other hand, is made by adding a chemical foaming agent like aluminum powder directly into the wet cement mix, causing hydrogen gas to form and generate air pockets during curing. Understanding these manufacturing differences helps you select the ideal material based on factors like density, strength, and thermal insulation requirements.

Physical Properties and Strength

Cellular concrete features a lower density range of 400-1600 kg/m3 and exhibits compressive strengths between 1 to 10 MPa, making it lightweight yet sufficiently strong for non-load-bearing applications. Aerated concrete, particularly autoclaved aerated concrete (AAC), typically has a density of 400-900 kg/m3 and demonstrates higher compressive strength up to 7 MPa, offering better thermal insulation and fire resistance. Your choice between cellular and aerated concrete should depend on the specific physical properties and structural strength requirements of your construction project.

Thermal and Acoustic Insulation Performance

Cellular concrete exhibits superior thermal insulation due to its dense network of closed air pockets, reducing heat transfer effectively compared to aerated concrete, which contains larger, interconnected pores. Acoustic insulation is enhanced in aerated concrete, as its porous structure absorbs and dampens sound waves better than the relatively more solid cellular concrete. Both materials contribute to energy efficiency and noise reduction, but cellular concrete excels in thermal resistance while aerated concrete offers improved soundproofing properties.

Fire Resistance Capabilities

Cellular concrete offers enhanced fire resistance due to its closed-cell structure that limits heat transfer and prevents the spread of flames, making it ideal for fireproofing applications. Aerated concrete also provides fire resistance, benefiting from its porous matrix that absorbs and dissipates heat efficiently, but it typically performs slightly less effectively compared to dense cellular variants. You can choose cellular concrete for superior fire protection in construction projects requiring high fire safety standards.

Applications in Construction

Cellular concrete, known for its lightweight and insulating properties, is widely used in road construction, trench backfill, and void filling where quick drying and easy application are essential. Aerated concrete is preferred in building construction for non-load-bearing walls, partitions, and insulation due to its excellent thermal performance and fire resistance. Your choice between these materials depends on structural requirements and specific application needs in construction projects.

Environmental Impact and Sustainability

Cellular concrete offers superior environmental benefits due to its use of recycled materials and lower energy consumption during production, significantly reducing carbon emissions compared to traditional aerated concrete. Aerated concrete, while lightweight and insulating, typically involves higher embodied energy and greater resource extraction, impacting sustainability efforts. Your choice between the two should consider cellular concrete's reduced environmental footprint and enhanced recyclability for greener construction projects.

Cost Comparison and Economic Analysis

Cellular concrete generally offers a lower cost per cubic meter compared to aerated concrete due to its simpler production process and the use of basic raw materials like cement, water, and foaming agents. Aerated concrete, often incorporating aluminum powder as a foaming agent, has higher manufacturing costs but provides superior insulation properties and strength, which can reduce long-term energy expenses. Your choice depends on balancing initial material costs with potential savings in energy efficiency and structural performance over the building's lifespan.

Choosing the Right Material: Key Considerations

Cellular concrete and aerated concrete differ primarily in density, thermal insulation, and strength, making material selection critical based on your project requirements. Cellular concrete offers higher density and compressive strength, suitable for load-bearing applications, while aerated concrete excels in lightweight insulation and fire resistance. Evaluating factors such as structural needs, thermal performance, and cost-efficiency ensures you choose the optimal material for sustainable and durable construction.

Cellular concrete vs aerated concrete Infographic

libmatt.com

libmatt.com