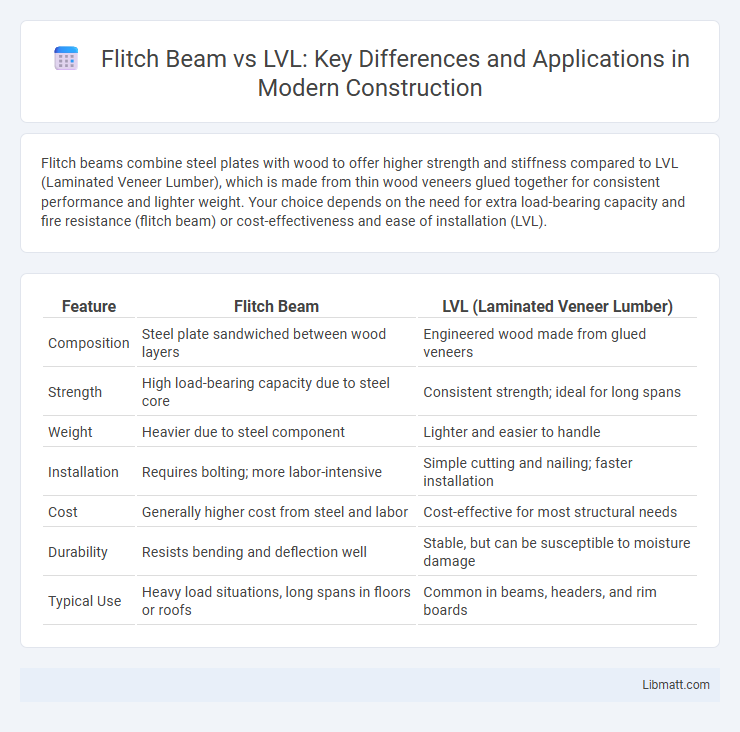

Flitch beams combine steel plates with wood to offer higher strength and stiffness compared to LVL (Laminated Veneer Lumber), which is made from thin wood veneers glued together for consistent performance and lighter weight. Your choice depends on the need for extra load-bearing capacity and fire resistance (flitch beam) or cost-effectiveness and ease of installation (LVL).

Table of Comparison

| Feature | Flitch Beam | LVL (Laminated Veneer Lumber) |

|---|---|---|

| Composition | Steel plate sandwiched between wood layers | Engineered wood made from glued veneers |

| Strength | High load-bearing capacity due to steel core | Consistent strength; ideal for long spans |

| Weight | Heavier due to steel component | Lighter and easier to handle |

| Installation | Requires bolting; more labor-intensive | Simple cutting and nailing; faster installation |

| Cost | Generally higher cost from steel and labor | Cost-effective for most structural needs |

| Durability | Resists bending and deflection well | Stable, but can be susceptible to moisture damage |

| Typical Use | Heavy load situations, long spans in floors or roofs | Common in beams, headers, and rim boards |

Introduction to Flitch Beam and LVL

Flitch beams combine steel plates with timber beams to enhance structural strength and rigidity, commonly used in floor joists and long-span applications. Laminated Veneer Lumber (LVL) is an engineered wood product made from thin wood veneers bonded under heat and pressure, offering consistent strength and dimensional stability for beams, headers, and rim boards. Both materials serve critical roles in modern construction, with flitch beams emphasizing hybrid strength and LVL prioritizing uniform performance and ease of handling.

Material Composition and Structure

Flitch beams combine steel plates sandwiched between wooden planks, offering enhanced strength and stiffness compared to traditional wood beams. LVL (Laminated Veneer Lumber) consists of multiple thin wood veneers bonded with adhesives, creating a uniform, engineered wood product known for its high load-bearing capacity and dimensional stability. Your choice between the two depends on the specific structural needs and environmental conditions of your project.

Manufacturing Process Comparison

Flitch beams are manufactured by sandwiching a steel plate between two layers of laminated veneer lumber (LVL) or solid wood, fastened together with bolts or nails, combining steel's strength with wood's flexibility. LVL beams are produced by bonding thin wood veneers with waterproof adhesives under heat and pressure, resulting in a uniform, engineered wood product with consistent strength and stiffness. Your choice between flitch beams and LVL depends on the specific structural demands and aesthetic preferences of your project.

Strength and Load-Bearing Capacity

Flitch beams combine steel plates with wood, offering superior strength and load-bearing capacity compared to LVL (Laminated Veneer Lumber) beams of similar dimensions, making them ideal for heavy structural loads. LVL beams provide consistent strength and stiffness due to their engineered wood composition, excelling in uniform load distribution but typically carrying less weight than flitch beams. Structural engineers often select flitch beams for renovation projects requiring enhanced load support, while LVL beams are preferred in new construction for efficiency and uniform performance.

Weight and Handling Considerations

Flitch beams, constructed by sandwiching a steel plate between two wooden beams, tend to be heavier and more challenging to handle compared to LVL (Laminated Veneer Lumber) beams, which are lighter and easier to maneuver on-site. The additional weight of flitch beams requires more labor and equipment during installation, potentially increasing project time and costs. Your choice between flitch beam and LVL should consider these weight and handling factors to ensure efficient construction and safety.

Installation Methods and Techniques

Flitch beams require bolting or welding steel plates to wooden joists on-site, demanding precise alignment and secure connections, often increasing installation time and labor costs. LVL (Laminated Veneer Lumber) beams are prefabricated and typically installed using standard nailing or screwing methods, allowing for quicker assembly and reduced need for specialized tools. The simplicity of LVL installation generally leads to faster project completion and less on-site adjustment compared to the more complex flitch beam technique.

Cost Analysis: Flitch Beam vs LVL

Flitch beams typically incur higher material and labor costs due to the combination of steel plates and timber, increasing fabrication complexity and installation time compared to Laminated Veneer Lumber (LVL). LVL offers a cost-effective alternative with consistent dimensions and strength, reducing waste and speeding up construction processes. When evaluating cost efficiency, LVL often provides better value for projects requiring longer spans and lighter structures, while flitch beams may be preferred for enhanced load-bearing capacity in specific designs.

Durability and Lifespan

Flitch beams, composed of steel plates sandwiched between wood laminations, offer superior durability and resistance to bending and twisting compared to LVL (Laminated Veneer Lumber), which may be more susceptible to moisture-related degradation. LVL beams, though engineered for strength and uniformity, typically have a shorter lifespan due to potential delamination and susceptibility to environmental factors if not properly sealed. Long-term durability for flitch beams is enhanced by the steel reinforcement, making them preferable in structural applications requiring high load-bearing capacity and extended lifespan.

Common Applications and Use Cases

Flitch beams are commonly used in renovation and retrofit projects where steel reinforcement is needed to increase load-bearing capacity without increasing beam depth significantly. LVL (Laminated Veneer Lumber) beams are preferred in new construction for floor joists, headers, and roof beams due to their consistent strength, dimensional stability, and ease of installation. Both materials excel in residential and commercial buildings, but LVL is more widespread for long spans and uniform loads, while flitch beams excel when combining steel's strength with timber aesthetics.

Environmental Impact and Sustainability

Flitch beams, composed of steel plates sandwiched between wood, offer durability but require significant energy for steel production, increasing their carbon footprint compared to Laminated Veneer Lumber (LVL), which is engineered from thin wood veneers bonded with adhesives. LVL is often considered more sustainable due to efficient wood utilization from fast-growing trees and lower embodied energy during manufacturing. Choosing LVL supports reduced deforestation and emissions, aligning better with environmentally conscious construction practices.

Flitch beam vs LVL Infographic

libmatt.com

libmatt.com