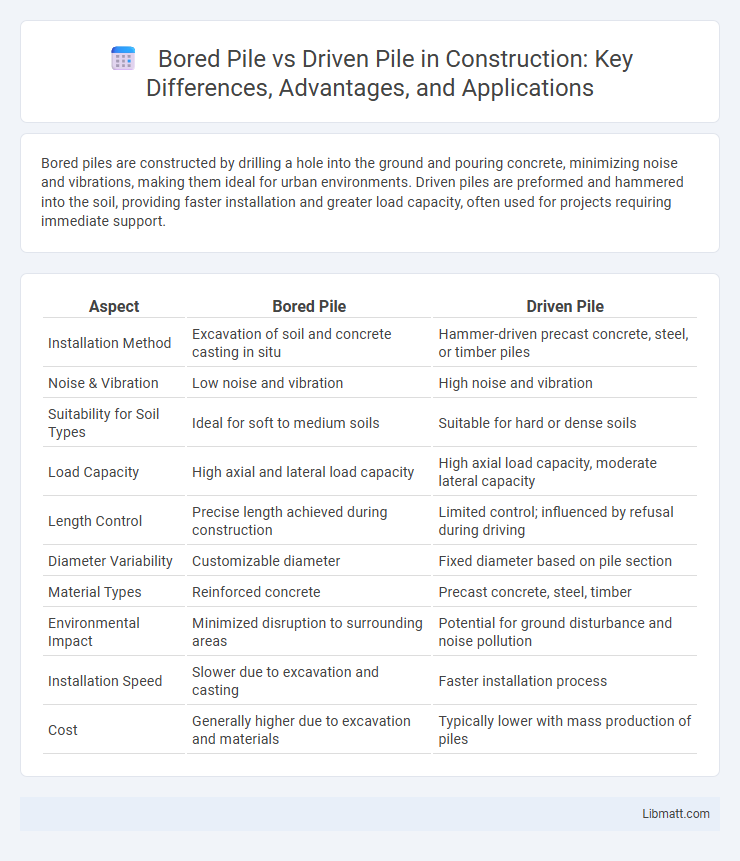

Bored piles are constructed by drilling a hole into the ground and pouring concrete, minimizing noise and vibrations, making them ideal for urban environments. Driven piles are preformed and hammered into the soil, providing faster installation and greater load capacity, often used for projects requiring immediate support.

Table of Comparison

| Aspect | Bored Pile | Driven Pile |

|---|---|---|

| Installation Method | Excavation of soil and concrete casting in situ | Hammer-driven precast concrete, steel, or timber piles |

| Noise & Vibration | Low noise and vibration | High noise and vibration |

| Suitability for Soil Types | Ideal for soft to medium soils | Suitable for hard or dense soils |

| Load Capacity | High axial and lateral load capacity | High axial load capacity, moderate lateral capacity |

| Length Control | Precise length achieved during construction | Limited control; influenced by refusal during driving |

| Diameter Variability | Customizable diameter | Fixed diameter based on pile section |

| Material Types | Reinforced concrete | Precast concrete, steel, timber |

| Environmental Impact | Minimized disruption to surrounding areas | Potential for ground disturbance and noise pollution |

| Installation Speed | Slower due to excavation and casting | Faster installation process |

| Cost | Generally higher due to excavation and materials | Typically lower with mass production of piles |

Introduction to Bored Pile and Driven Pile

Bored piles are deep foundation elements created by drilling a hole into the ground and filling it with concrete, making them ideal for sites with limited access and minimal vibration concerns. Driven piles, on the other hand, are prefabricated piles hammered into the ground using pile drivers, offering high load capacity and rapid installation in firm soil conditions. Your selection between bored pile and driven pile depends on soil properties, site constraints, and structural load requirements.

Definition and Construction Methods

Bored piles are deep foundation elements constructed by drilling a cylindrical hole into the ground using a rotary drilling rig and then filling it with reinforced concrete, providing a non-displacement method suitable for urban areas with limited vibration tolerance. Driven piles consist of preformed concrete, steel, or timber sections that are mechanically hammered or vibrated into the soil, offering a displacement method that compacts surrounding soil and enhances load capacity. The construction of bored piles requires temporary casing or drilling fluids to maintain borehole stability, while driven piles rely on pile driving hammers and leads for precise installation and load transfer.

Material and Equipment Requirements

Bored piles require reinforced concrete and steel casing, with specialized drilling rigs to excavate deep shafts, making them suitable for sites with restricted noise or vibration limits. Driven piles typically involve pre-formed concrete, timber, or steel piles, installed using pile drivers or hydraulic hammers that deliver high-impact force to penetrate soil layers efficiently. Your choice depends on site conditions and equipment availability, as bored piles demand complex machinery while driven piles require heavy-impact driving equipment.

Load-Bearing Capacity Comparison

Bored piles generally offer higher load-bearing capacity due to their larger diameter and ability to be reinforced with steel cages, providing greater stability in weak soil conditions. Driven piles deliver consistent load-bearing performance by compacting surrounding soil during installation, enhancing frictional resistance and load transfer. Soil type, pile material, and installation method significantly influence the ultimate load capacity of both bored and driven piles.

Suitability for Different Soil Conditions

Bored piles are ideal for soft, loose, or water-logged soils where minimal vibration and disturbance are essential, as they involve excavating a hole before concreting. Driven piles perform well in dense, granular, or stiff soils where high driving resistance ensures stability and load-bearing capacity through compaction of surrounding soil. Soil conditions like groundwater level and soil density significantly influence the choice between bored and driven piles for optimal foundation performance.

Installation Speed and Project Timeline

Driven piles offer faster installation speeds since they are rapidly hammered into the ground, reducing overall project timelines significantly. Bored piles require more time due to excavation, casing, and curing processes, which can extend project duration. Choosing driven piles can accelerate your construction schedule, especially in projects requiring quick foundation solutions.

Environmental Impact and Site Disturbance

Bored piles generate less noise and vibration compared to driven piles, minimizing disturbance to surrounding environments and nearby structures. Driven piles often cause significant ground vibration and noise pollution, which can disrupt wildlife and residential areas. Site disturbance is reduced with bored piles as excavation is localized, whereas driven piles require heavy equipment and repeated impact driving, increasing soil compaction and surface disruption.

Cost Analysis: Bored Pile vs Driven Pile

Bored piles generally incur higher initial construction costs due to the need for specialized drilling equipment and longer installation times compared to driven piles, which utilize faster, repetitive hammer driving methods reducing labor expenses. Driven piles often require less site preparation and can be installed quickly, making them cost-effective for projects with tight schedules or firm ground conditions. However, maintenance and noise mitigation expenses may increase costs for driven piles in urban environments, whereas bored piles exhibit lower vibration impacts and suit sensitive sites despite their higher upfront investment.

Common Applications and Usage Scenarios

Bored piles are commonly used in urban construction projects requiring minimal noise and vibration, such as high-rise buildings and bridges, where soil conditions allow for large diameter and depth customization. Driven piles are preferred in sites with dense soils or where rapid installation is needed, commonly applied in marine structures, industrial facilities, and foundations requiring high load capacity. Selection depends on factors like soil type, load requirements, environmental constraints, and project timeline.

Advantages and Disadvantages Summary

Bored piles offer advantages such as minimal noise and vibration, suitability for urban areas, and the ability to construct large-diameter piles to support heavy loads, but they tend to be slower and more expensive due to complex drilling processes. Driven piles provide rapid installation, higher load capacity per unit length, and improved soil compaction around the pile, although they cause significant noise, vibration, and potential damage to nearby structures. The choice between bored piles and driven piles depends on site conditions, environmental sensitivity, load requirements, and budget constraints.

Bored pile vs driven pile Infographic

libmatt.com

libmatt.com