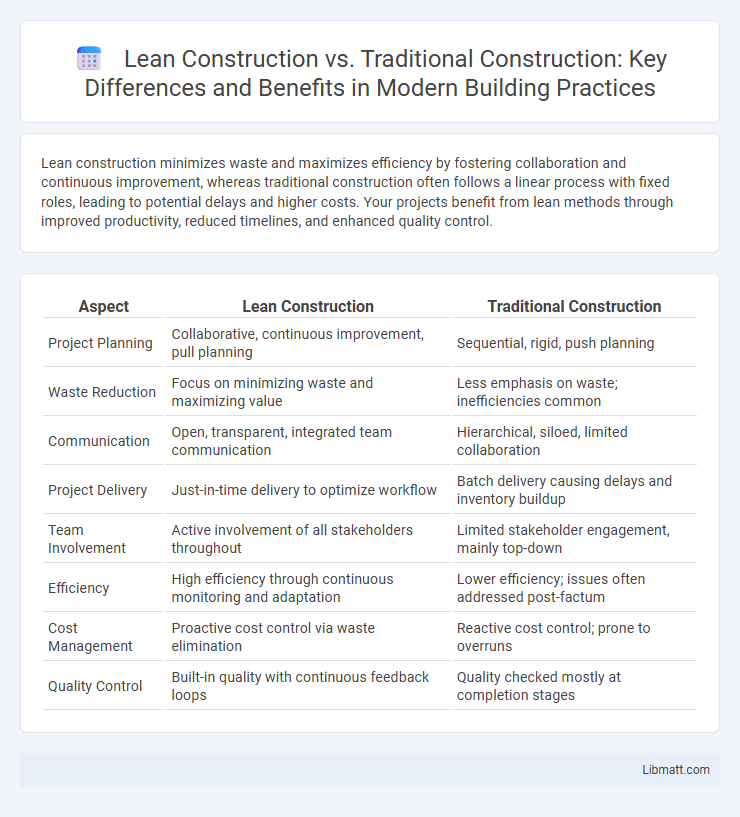

Lean construction minimizes waste and maximizes efficiency by fostering collaboration and continuous improvement, whereas traditional construction often follows a linear process with fixed roles, leading to potential delays and higher costs. Your projects benefit from lean methods through improved productivity, reduced timelines, and enhanced quality control.

Table of Comparison

| Aspect | Lean Construction | Traditional Construction |

|---|---|---|

| Project Planning | Collaborative, continuous improvement, pull planning | Sequential, rigid, push planning |

| Waste Reduction | Focus on minimizing waste and maximizing value | Less emphasis on waste; inefficiencies common |

| Communication | Open, transparent, integrated team communication | Hierarchical, siloed, limited collaboration |

| Project Delivery | Just-in-time delivery to optimize workflow | Batch delivery causing delays and inventory buildup |

| Team Involvement | Active involvement of all stakeholders throughout | Limited stakeholder engagement, mainly top-down |

| Efficiency | High efficiency through continuous monitoring and adaptation | Lower efficiency; issues often addressed post-factum |

| Cost Management | Proactive cost control via waste elimination | Reactive cost control; prone to overruns |

| Quality Control | Built-in quality with continuous feedback loops | Quality checked mostly at completion stages |

Introduction to Lean Construction and Traditional Construction

Lean construction streamlines project delivery by minimizing waste and enhancing collaboration throughout the building process, leading to increased efficiency and reduced costs. Traditional construction often relies on linear workflows and compartmentalized roles, which can result in slower progress and higher resource consumption. Understanding the differences helps you choose methodologies that optimize timelines and improve overall project outcomes.

Key Principles of Lean Construction

Lean construction emphasizes continuous improvement, waste reduction, and just-in-time delivery to enhance project efficiency and value. Key principles include collaborative planning, transparency in workflow, and proactive problem-solving to minimize delays and cost overruns. Your projects benefit from improved communication and streamlined processes compared to traditional construction methods, which often face fragmentation and inefficiencies.

Core Characteristics of Traditional Construction

Traditional construction is characterized by a linear process with distinct, sequential phases including design, procurement, and construction, often leading to extended project timelines and higher costs. It relies heavily on hierarchical management structures and individual subcontractor responsibilities, which can result in communication gaps and inefficiencies. You may experience increased waste and lower productivity due to the lack of integrated planning and collaboration inherent in traditional construction methods.

Project Planning and Management Approaches

Lean construction emphasizes collaborative project planning with continuous feedback loops to minimize waste and maximize value, utilizing techniques like Last Planner System for reliable workflow management. Traditional construction often relies on linear, sequential planning with rigid schedules, which can lead to inefficiencies and delays due to limited stakeholder engagement. Lean's adaptive approach fosters real-time problem-solving and resource optimization, contrasting with traditional methods that typically follow predetermined plans without frequent adjustments.

Cost Efficiency and Budget Control

Lean construction significantly enhances cost efficiency by minimizing waste, optimizing resource allocation, and improving workflow through just-in-time deliveries and collaborative planning. Traditional construction often faces budget overruns due to fragmented processes, delays, and inefficient material management. Implementing lean methodologies leads to better budget control by enabling real-time tracking, reducing rework, and fostering continuous improvement throughout the project lifecycle.

Time Management and Project Deadlines

Lean construction significantly improves time management by emphasizing workflow efficiency and continuous process optimization, reducing project delays and waste. Traditional construction often relies on sequential task completion, which can lead to bottlenecks and missed deadlines due to less adaptive scheduling. Lean methods utilize just-in-time delivery and real-time collaboration, ensuring stricter adherence to project deadlines and faster overall completion.

Quality Assurance and Performance Outcomes

Lean construction emphasizes continuous quality assurance through collaborative workflows and real-time problem-solving, resulting in higher performance outcomes and reduced waste compared to traditional construction. Traditional construction often relies on sequential processes and post-completion inspections, which can lead to delayed defect detection and lower overall project efficiency. Studies indicate Lean methodologies improve project delivery times by up to 30% and significantly enhance quality metrics through standardized work and continuous feedback loops.

Waste Reduction and Sustainability Practices

Lean construction significantly reduces waste by emphasizing continuous improvement, just-in-time delivery, and efficient resource allocation, which minimizes material surplus and environmental impact. Traditional construction often generates excess waste due to less coordinated workflows and bulk material ordering, leading to higher disposal costs and ecological footprint. Your project benefits from lean construction's sustainability practices by enhancing resource efficiency and reducing greenhouse gas emissions throughout the building lifecycle.

Collaboration and Team Communication

Lean construction prioritizes collaboration and transparent communication by integrating all project stakeholders through continuous feedback loops and shared goals, which reduces errors and accelerates decision-making. Traditional construction often relies on hierarchical communication channels, leading to fragmented information flow and delayed problem resolution. Enhanced teamwork in lean construction fosters real-time updates, improving overall project efficiency and reducing costly rework.

Choosing the Right Approach for Your Project

Lean construction optimizes efficiency by minimizing waste, improving collaboration, and accelerating project delivery, making it ideal for projects requiring tight schedules and cost control. Traditional construction follows a linear process with defined phases, which can lead to longer timelines and higher risks of delays and budget overruns. Choosing the right approach depends on your project's complexity, timeline flexibility, and emphasis on continuous improvement versus established workflow structures.

Lean construction vs Traditional construction Infographic

libmatt.com

libmatt.com