Self-leveling concrete offers a faster and more efficient application compared to traditional screed, providing a smooth, even surface with minimal effort. You can achieve superior durability and a thinner application with self-leveling concrete, reducing drying time and improving overall floor performance.

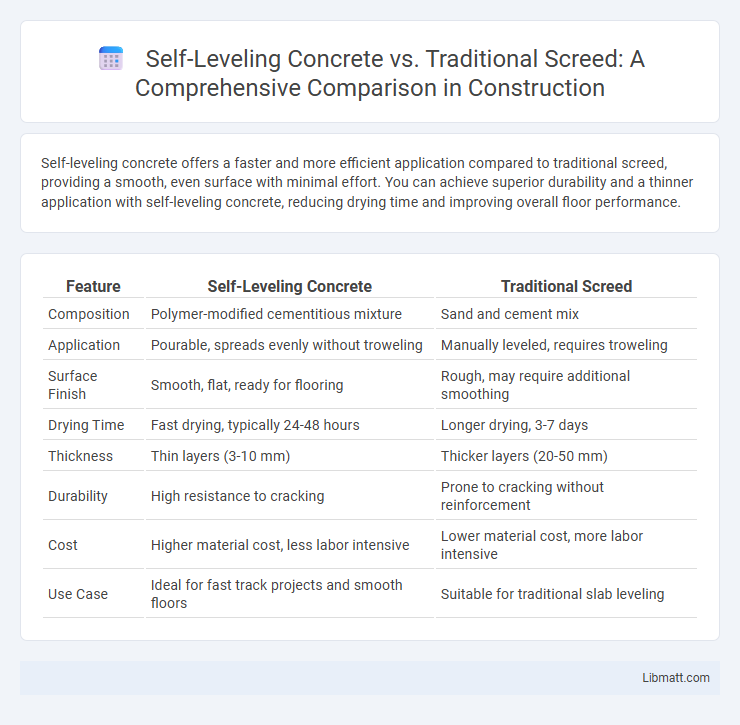

Table of Comparison

| Feature | Self-Leveling Concrete | Traditional Screed |

|---|---|---|

| Composition | Polymer-modified cementitious mixture | Sand and cement mix |

| Application | Pourable, spreads evenly without troweling | Manually leveled, requires troweling |

| Surface Finish | Smooth, flat, ready for flooring | Rough, may require additional smoothing |

| Drying Time | Fast drying, typically 24-48 hours | Longer drying, 3-7 days |

| Thickness | Thin layers (3-10 mm) | Thicker layers (20-50 mm) |

| Durability | High resistance to cracking | Prone to cracking without reinforcement |

| Cost | Higher material cost, less labor intensive | Lower material cost, more labor intensive |

| Use Case | Ideal for fast track projects and smooth floors | Suitable for traditional slab leveling |

Introduction to Self-Leveling Concrete and Traditional Screed

Self-leveling concrete is a polymer-modified cementitious material designed to flow and spread evenly without mechanical compaction, creating a smooth, flat surface quickly. Traditional screed consists of a sand and cement mix applied and leveled manually to provide a base for floor finishes but often requires more time and labor to achieve a uniform surface. Self-leveling concrete offers superior flowability and faster curing times compared to traditional screed, enhancing installation efficiency and finish quality.

Composition and Material Differences

Self-leveling concrete contains polymer-modified cementitious materials with fine aggregates and chemical additives that enhance flowability and rapid setting, allowing it to spread evenly without mechanical leveling. Traditional screed consists mainly of cement, sand, and water, requiring manual spreading and leveling, resulting in a coarser texture and longer curing time. The inclusion of polymers and additives in self-leveling concrete improves adhesion, reduces shrinkage, and increases durability compared to the conventional sand-cement base of traditional screeds.

Application Techniques Compared

Self-leveling concrete features a pour-and-spread application that flows easily to create a smooth, level surface with minimal effort, ideal for uneven floors and rapid project completion. Traditional screed requires manual mixing, spreading, and leveling, often involving screeding tools to achieve the desired thickness and flatness, making it more labor-intensive and time-consuming. Your choice depends on project scale, time constraints, and surface condition, with self-leveling concrete offering greater efficiency for fast, precise leveling.

Surface Preparation Requirements

Self-leveling concrete requires minimal surface preparation, often just cleaning and priming to ensure proper adhesion, making it ideal for quick applications. Traditional screed demands extensive surface work, including thorough leveling, moisture checks, and sometimes a bonding agent to prevent cracks or detachment. Your choice depends on the project's time constraints and the condition of the existing substrate.

Curing Times and Project Timelines

Self-leveling concrete typically cures within 2 to 4 hours, significantly reducing project timelines compared to traditional screed, which requires 24 to 72 hours for curing. This rapid curing allows Your flooring installation or finishing work to proceed quickly, minimizing downtime. Choosing self-leveling concrete enhances efficiency on time-sensitive projects due to its faster drying and readiness for subsequent construction phases.

Suitability for Various Flooring Types

Self-leveling concrete offers exceptional suitability for a wide range of flooring types, including tile, vinyl, laminate, and hardwood, due to its smooth, even surface that minimizes the need for additional floor preparation. Traditional screed is more versatile for thicker layers and uneven substrates but may require additional smoothing or sanding before installing delicate floor coverings like engineered wood or thin vinyl. Choosing self-leveling concrete ensures optimal adhesion and durability for modern, sensitive flooring materials, whereas traditional screed suits heavy-duty applications with rougher surface needs.

Strength and Durability Assessment

Self-leveling concrete typically exhibits higher compressive strength, often ranging from 3,000 to 5,000 psi, compared to traditional screed which usually has a lower strength around 2,000 to 3,000 psi. The enhanced durability of self-leveling concrete is attributed to its polymer-modified composition, providing better resistance to cracking, shrinking, and moisture penetration. Traditional screed, while adequate for basic leveling, tends to be more prone to surface wear and structural degradation under heavy foot traffic or mechanical stress.

Cost Comparison and Budget Considerations

Self-leveling concrete typically costs more upfront than traditional screed due to its specialized materials and faster application process, but it can reduce labor expenses and project timelines, potentially saving money in overall budget considerations. Traditional screed is cheaper per square meter but requires more labor and time for proper leveling, which can increase indirect costs, especially in large or complex projects. Your choice should weigh immediate material costs against long-term labor savings and project efficiency to optimize budget outcomes.

Common Challenges and Solutions

Self-leveling concrete often encounters challenges like rapid curing and shrinkage cracks, while traditional screed may suffer from uneven surfaces and longer drying times. Effective solutions for self-leveling concrete include using admixtures to control set time and applying proper curing techniques to minimize cracks. For traditional screed, ensuring accurate mixing ratios and implementing mechanical leveling tools can improve surface uniformity and durability for Your flooring projects.

Choosing the Right Option for Your Project

Self-leveling concrete offers faster application and superior smoothness, making it ideal for projects requiring quick turnaround and minimal surface preparation. Traditional screed provides greater thickness flexibility and is better suited for uneven substrates or when embedding pipes and heating systems. Assess your project's specific needs for speed, surface finish, and structural requirements to choose the optimal material.

Self-leveling concrete vs Traditional screed Infographic

libmatt.com

libmatt.com