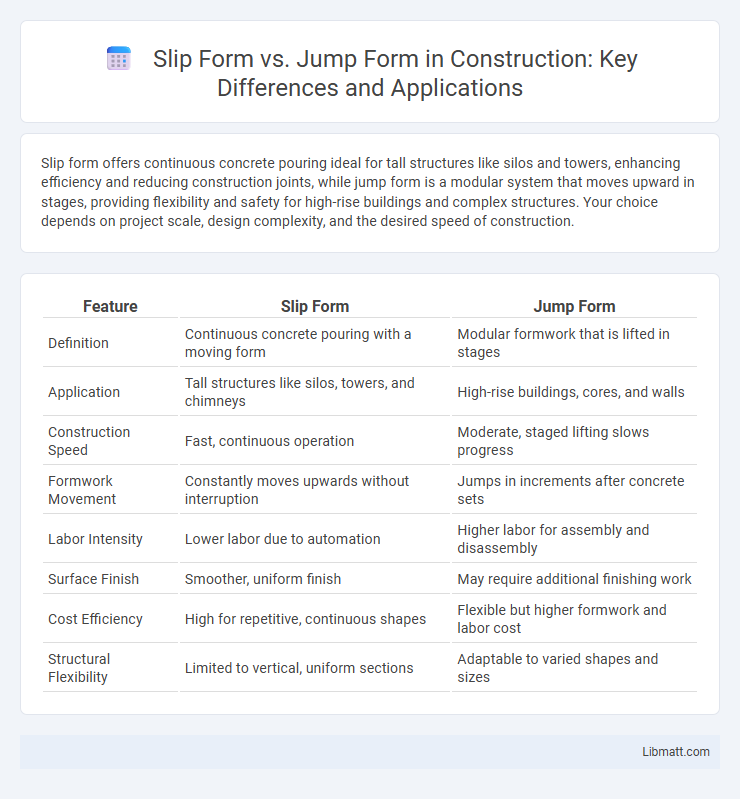

Slip form offers continuous concrete pouring ideal for tall structures like silos and towers, enhancing efficiency and reducing construction joints, while jump form is a modular system that moves upward in stages, providing flexibility and safety for high-rise buildings and complex structures. Your choice depends on project scale, design complexity, and the desired speed of construction.

Table of Comparison

| Feature | Slip Form | Jump Form |

|---|---|---|

| Definition | Continuous concrete pouring with a moving form | Modular formwork that is lifted in stages |

| Application | Tall structures like silos, towers, and chimneys | High-rise buildings, cores, and walls |

| Construction Speed | Fast, continuous operation | Moderate, staged lifting slows progress |

| Formwork Movement | Constantly moves upwards without interruption | Jumps in increments after concrete sets |

| Labor Intensity | Lower labor due to automation | Higher labor for assembly and disassembly |

| Surface Finish | Smoother, uniform finish | May require additional finishing work |

| Cost Efficiency | High for repetitive, continuous shapes | Flexible but higher formwork and labor cost |

| Structural Flexibility | Limited to vertical, uniform sections | Adaptable to varied shapes and sizes |

Introduction to Slip Form and Jump Form

Slip form and jump form are advanced concrete construction techniques designed to accelerate high-rise building projects. Slip form involves continuous pouring of concrete into a moving formwork that "slips" upwards steadily, optimizing vertical construction speed. Jump form uses a modular, climbable formwork system that is repositioned in stages, allowing for precision and adaptability in building complex structural elements.

Definition and Core Concepts

Slip form is a continuous concrete pouring technique used to construct vertical structures like silos and towers by moving formwork gradually upward as the concrete sets. Jump form involves a reusable climbing formwork system that is lifted in stages to build high-rise buildings or bridges incrementally. The core concept of slip form centers on seamless, uninterrupted progress, while jump form emphasizes modular, repeatable lifting for complex structural geometries.

How Slip Form Works

Slip form works by continuously pouring concrete into a moving formwork that slowly rises as the concrete sets, enabling an uninterrupted vertical construction process. The formwork is supported by hydraulic jacks that climb the structure, allowing for consistent shaping of walls, columns, or silos without the need for horizontal joints. This method enhances efficiency and structural uniformity in tall, vertical concrete elements compared to traditional jump form systems.

How Jump Form Works

Jump form works by climbing up the building structure using hydraulic jacks, allowing the formwork to move vertically along with the project's progress. This system supports the construction of tall concrete cores or walls by enabling continuous pouring without the need to dismantle and reset formwork at each level. Your construction efficiency improves as jump forms minimize downtime and enhance worker safety during high-rise builds.

Key Differences Between Slip Form and Jump Form

Slip form and jump form are two distinct construction techniques with key differences in operation and application. Slip form involves continuous, upward movement of formwork to create structures like silos or towers without form disassembly, optimizing speed and uniformity. Jump form, alternatively, requires periodic repositioning of formwork, suitable for high-rise buildings with repetitive floors, offering modular flexibility and ease of adjustment for complex shapes.

Advantages of Slip Form Construction

Slip form construction offers continuous, seamless concrete pouring that enhances structural integrity and reduces joints, resulting in improved durability and resistance to environmental factors. This method accelerates the building process by enabling faster cycle times and minimizing labor costs, which optimizes project timelines and budget efficiency. You gain increased design flexibility with slip form, allowing for customized shapes and variable cross-sections in tall structures like silos, towers, and high-rise buildings.

Benefits of Jump Form Construction

Jump form construction offers enhanced safety and efficiency by allowing continuous vertical concrete pouring without the need for extensive formwork dismantling. This method reduces labor costs and accelerates project timelines by enabling rapid, repetitive floor cycle completions. Its adaptability to complex architectural designs ensures precise alignment and structural integrity in high-rise buildings.

Limitations and Challenges of Each Method

Slip form construction faces challenges such as limited adaptability to complex geometries and a need for continuous concrete pour, which can cause logistical difficulties and increased labor demands. Jump form methods encounter limitations in slower cycle times and higher costs due to the disassembly and reassembly of formwork at each lift, impacting schedule efficiency. Both techniques require careful planning for safety and precision, with slip forms being less flexible for variable wall thicknesses and jump forms demanding significant coordination for form repositioning.

Typical Applications and Case Studies

Slip form is typically used in continuous, vertical construction projects such as silos, bridges, and high-rise cores where uninterrupted concrete pouring ensures structural integrity. Jump form is favored for multi-story buildings and complex urban projects, allowing work on multiple floors simultaneously through the repositioning of formwork. Your choice depends on project scale and speed, with case studies showing slip form excelling in tall infrastructures and jump form optimizing efficiency in dense, staged constructions.

Choosing the Right Method for Your Project

Slip form and jump form are crucial concrete construction techniques, with slip form ideal for continuous vertical structures like silos and towers, offering seamless, rapid progress. Jump form suits high-rise buildings requiring precise, repetitive, and modular formwork, ensuring superior safety and structural integrity. Your project's height, complexity, and timeline determine the optimal method for maximum efficiency and cost-effectiveness.

Slip form vs jump form Infographic

libmatt.com

libmatt.com