A vapor barrier is a material designed to completely block the passage of moisture vapor, providing maximum protection against water infiltration, while a vapor retarder allows limited moisture diffusion to prevent condensation and mold growth. Choosing the right option depends on your climate and construction needs to balance moisture control and building breathability.

Table of Comparison

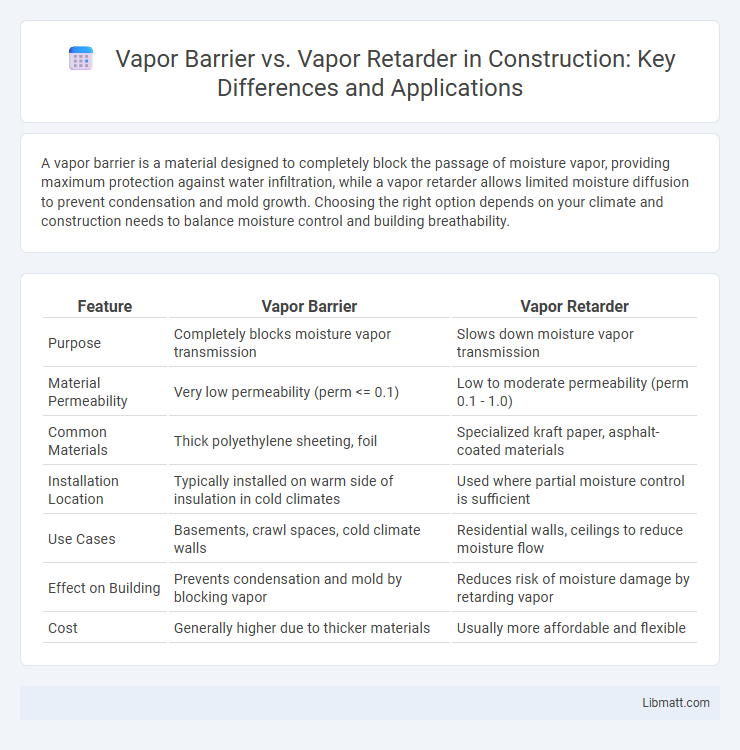

| Feature | Vapor Barrier | Vapor Retarder |

|---|---|---|

| Purpose | Completely blocks moisture vapor transmission | Slows down moisture vapor transmission |

| Material Permeability | Very low permeability (perm <= 0.1) | Low to moderate permeability (perm 0.1 - 1.0) |

| Common Materials | Thick polyethylene sheeting, foil | Specialized kraft paper, asphalt-coated materials |

| Installation Location | Typically installed on warm side of insulation in cold climates | Used where partial moisture control is sufficient |

| Use Cases | Basements, crawl spaces, cold climate walls | Residential walls, ceilings to reduce moisture flow |

| Effect on Building | Prevents condensation and mold by blocking vapor | Reduces risk of moisture damage by retarding vapor |

| Cost | Generally higher due to thicker materials | Usually more affordable and flexible |

Understanding Moisture Control in Buildings

Vapor barriers and vapor retarders are essential components for moisture control in buildings, designed to prevent the passage of water vapor through walls and ceilings. Vapor barriers have a permeability rating of 0.1 perm or less, effectively blocking moisture, while vapor retarders allow limited vapor transmission with ratings between 0.1 and 1 perm, reducing condensation risks without trapping moisture. Selecting the appropriate material depends on climate, building design, and vapor drive direction to maintain structural integrity and indoor air quality.

What Is a Vapor Barrier?

A vapor barrier is a material specifically designed to prevent moisture from passing through walls, ceilings, and floors, typically composed of polyethylene plastic or foil. It works by creating a continuous, impermeable layer that blocks water vapor diffusion, crucial in preventing mold growth and structural damage in buildings. Vapor barriers are essential in climates with high humidity to maintain indoor air quality and protect insulation effectiveness.

What Is a Vapor Retarder?

A vapor retarder is a material designed to slow down the movement of moisture through walls, ceilings, and floors, helping to control condensation and prevent mold growth. Unlike a vapor barrier, which completely blocks moisture, a vapor retarder allows limited vapor diffusion, balancing moisture control with breathability. Your choice of a vapor retarder depends on climate conditions and building design to maintain indoor air quality and structural integrity.

Key Differences Between Vapor Barriers and Vapor Retarders

Vapor barriers are materials with a perm rating of 0.1 or less, designed to completely block moisture transmission, while vapor retarders have a higher perm rating, slowing but not fully preventing vapor movement. Your choice between these depends on the climate, building design, and moisture control needs, as vapor barriers are typically used in colder climates to prevent condensation inside walls. Vapor retarders provide controlled moisture diffusion, suitable for mixed or warmer climates where some drying is necessary to maintain structural integrity and indoor air quality.

Classification of Vapor Retarders by Permeance

Vapor barriers and vapor retarders differ primarily in their permeance ratings, which classify their ability to restrict moisture vapor transmission. Vapor barriers have a permeance of 0.1 perms or less, effectively blocking almost all moisture movement, while vapor retarders have permeance values between 0.1 and 1.0 perms, allowing limited vapor diffusion. Understanding these classifications helps you select the appropriate material to control moisture and protect building assemblies.

Common Materials Used for Vapor Barriers and Retarders

Common materials used for vapor barriers include polyethylene plastic sheets, aluminum foil, and reinforced vinyl, which provide nearly impermeable layers to moisture. Vapor retarders often utilize kraft-faced fiberglass insulation, asphalt-coated kraft paper, and specialty paints designed to reduce vapor transmission without fully blocking it. Selecting the appropriate material depends on the required permeance rating and the specific climate conditions of the building site.

When to Use a Vapor Barrier vs. Vapor Retarder

Use a vapor barrier when you need to completely block moisture transmission, such as in cold climates or under concrete slabs to prevent water vapor from entering your building envelope. Vapor retarders are suitable for controlling, but not fully stopping, moisture diffusion in moderate climates or areas like walls and ceilings where slight permeability helps prevent condensation. Understanding the specific vapor permeability ratings and local building codes ensures you choose the right material to protect your structure efficiently.

Installation Best Practices

Proper installation of vapor barriers involves creating a continuous, impermeable layer usually on the warm side of insulation to prevent moisture migration and condensation within wall assemblies. Vapor retarders, offering controlled permeability, should be installed to balance moisture diffusion, often using materials with a perm rating between 0.1 and 1, and placed based on regional climate conditions and building use. Ensuring tight seams, sealing penetrations with compatible tapes or sealants, and integrating ventilation or drainage systems are critical best practices to maintain the effectiveness of both vapor barriers and retarders in building envelopes.

Regional Climate Considerations

Vapor barriers are essential in cold climates to prevent moisture from migrating into wall cavities and causing insulation damage or mold growth, while vapor retarders are more suitable for mixed or warm climates where some moisture permeability is beneficial to allow drying. In regions with high humidity, such as coastal or tropical areas, vapor retarders help balance moisture control and breathability, preventing trapped condensation that could degrade building materials. Selecting appropriate vapor control materials based on regional climate types ensures optimal indoor air quality, structural durability, and energy efficiency.

Common Mistakes and How to Avoid Them

Confusing vapor barriers with vapor retarders often leads to improper moisture control, causing mold growth and structural damage. Your choice should be based on climate conditions and building type, with vapor barriers typically used in colder climates to completely block moisture and vapor retarders in mixed or warm climates to slow vapor diffusion. Avoid common errors by consulting building codes and using appropriate material permeance ratings to ensure effective moisture management.

Vapor barrier vs vapor retarder Infographic

libmatt.com

libmatt.com