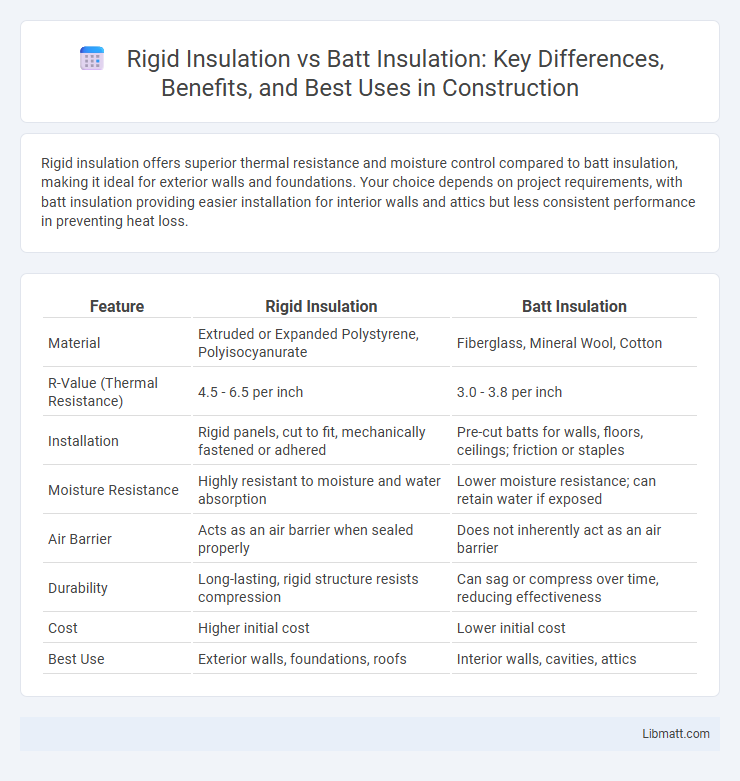

Rigid insulation offers superior thermal resistance and moisture control compared to batt insulation, making it ideal for exterior walls and foundations. Your choice depends on project requirements, with batt insulation providing easier installation for interior walls and attics but less consistent performance in preventing heat loss.

Table of Comparison

| Feature | Rigid Insulation | Batt Insulation |

|---|---|---|

| Material | Extruded or Expanded Polystyrene, Polyisocyanurate | Fiberglass, Mineral Wool, Cotton |

| R-Value (Thermal Resistance) | 4.5 - 6.5 per inch | 3.0 - 3.8 per inch |

| Installation | Rigid panels, cut to fit, mechanically fastened or adhered | Pre-cut batts for walls, floors, ceilings; friction or staples |

| Moisture Resistance | Highly resistant to moisture and water absorption | Lower moisture resistance; can retain water if exposed |

| Air Barrier | Acts as an air barrier when sealed properly | Does not inherently act as an air barrier |

| Durability | Long-lasting, rigid structure resists compression | Can sag or compress over time, reducing effectiveness |

| Cost | Higher initial cost | Lower initial cost |

| Best Use | Exterior walls, foundations, roofs | Interior walls, cavities, attics |

Overview of Rigid Insulation and Batt Insulation

Rigid insulation consists of dense foam panels that provide high thermal resistance and moisture control, ideal for exterior walls, roofs, and foundations. Batt insulation, made from fiberglass or mineral wool, fits between wall studs and joists, offering cost-effective thermal and sound insulation with easy installation. Your choice depends on the specific application, desired R-value, and moisture management needs.

Material Composition and Structure

Rigid insulation is typically made from polyisocyanurate, extruded polystyrene (XPS), or expanded polystyrene (EPS), featuring a dense, closed-cell structure that provides superior thermal resistance and moisture resistance. Batt insulation is primarily composed of fiberglass or mineral wool fibers, arranged in loose, fluffy layers that trap air to slow heat transfer but offer lower moisture resistance. The solid, continuous panels of rigid insulation give it higher compressive strength and durability compared to the flexible, compressible form of batt insulation.

Installation Methods: Rigid vs. Batt Insulation

Rigid insulation installation involves cutting foam panels to fit specific wall or roof spaces, which requires precise measurements and sealing edges with foam or tape to prevent air leaks. Batt insulation is typically installed between studs or joists by pressing the flexible fiberglass or mineral wool batts into place, making it easier for DIY projects but potentially susceptible to gaps if improperly fitted. Your choice of insulation impacts ease of installation and effectiveness, with rigid boards offering a continuous thermal barrier and batt insulation providing quicker, more adaptable coverage in framed spaces.

Thermal Performance and R-Value Comparison

Rigid insulation offers superior thermal performance due to its higher R-value per inch, typically ranging from R-4 to R-6.5, compared to batt insulation, which usually provides R-values between R-2.9 and R-3.8. Choosing rigid insulation for your project ensures enhanced energy efficiency and consistent thermal resistance, especially in areas requiring moisture resistance and structural support.

Moisture Resistance and Durability

Rigid insulation offers superior moisture resistance compared to batt insulation due to its closed-cell structure that prevents water absorption and reduces the risk of mold growth. Batt insulation, typically made from fiberglass or mineral wool, is more susceptible to moisture infiltration, which can compromise its thermal performance and lead to degradation over time. Durability of rigid insulation surpasses batt insulation as it maintains structural integrity under compressive forces and varying environmental conditions, extending its lifespan in building envelopes.

Cost Differences and Budget Considerations

Rigid insulation generally has a higher upfront cost compared to batt insulation due to its denser material and superior thermal resistance. Batt insulation offers a budget-friendly option with easier installation, making it suitable for projects with tight financial constraints. Evaluating your long-term energy savings against initial expenses is essential for making the best decision for your insulation investment.

Ideal Applications for Rigid Insulation

Rigid insulation is ideal for exterior wall sheathing, basement walls, and roofing systems where moisture resistance and high compressive strength are essential. It provides superior thermal performance and durability in areas exposed to harsh weather or heavy loads, making it suitable for insulating structural components and foundation walls. Your choice of rigid insulation enhances energy efficiency and prevents thermal bridging in both residential and commercial buildings.

Suitable Uses for Batt Insulation

Batt insulation is ideal for framing cavities in walls, floors, and ceilings where it can be easily fitted between studs, joists, and rafters. It provides good thermal resistance and soundproofing in residential and commercial buildings, particularly in wood-framed construction. Your choice of batt insulation should consider factors like moisture control and proper installation to maximize energy efficiency and comfort.

Energy Efficiency and Long-Term Savings

Rigid insulation offers higher R-value per inch compared to batt insulation, providing superior energy efficiency by reducing heat transfer and maintaining consistent indoor temperatures. This increased thermal resistance results in lower HVAC energy consumption and significant long-term savings on utility bills. Batt insulation, while easier to install, often has gaps and compression issues that reduce its effectiveness, leading to less reliable energy performance and higher costs over time.

Environmental Impact and Sustainability

Rigid insulation typically offers a higher R-value per inch than batt insulation, leading to better energy efficiency and a reduced carbon footprint over the lifespan of a building. Batt insulation, often made from fiberglass or mineral wool, can have a lower environmental impact when sourced from recycled materials, but it may require thicker layers and more frequent replacement. Choosing rigid insulation can enhance your project's sustainability by minimizing heat loss and decreasing energy consumption, contributing to long-term environmental benefits.

Rigid insulation vs batt insulation Infographic

libmatt.com

libmatt.com