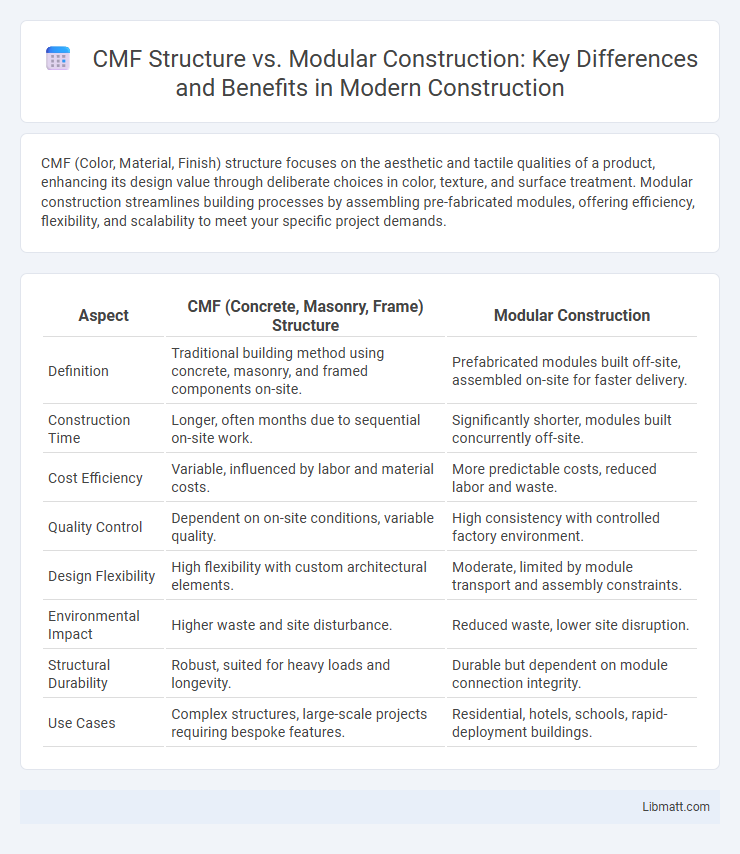

CMF (Color, Material, Finish) structure focuses on the aesthetic and tactile qualities of a product, enhancing its design value through deliberate choices in color, texture, and surface treatment. Modular construction streamlines building processes by assembling pre-fabricated modules, offering efficiency, flexibility, and scalability to meet your specific project demands.

Table of Comparison

| Aspect | CMF (Concrete, Masonry, Frame) Structure | Modular Construction |

|---|---|---|

| Definition | Traditional building method using concrete, masonry, and framed components on-site. | Prefabricated modules built off-site, assembled on-site for faster delivery. |

| Construction Time | Longer, often months due to sequential on-site work. | Significantly shorter, modules built concurrently off-site. |

| Cost Efficiency | Variable, influenced by labor and material costs. | More predictable costs, reduced labor and waste. |

| Quality Control | Dependent on on-site conditions, variable quality. | High consistency with controlled factory environment. |

| Design Flexibility | High flexibility with custom architectural elements. | Moderate, limited by module transport and assembly constraints. |

| Environmental Impact | Higher waste and site disturbance. | Reduced waste, lower site disruption. |

| Structural Durability | Robust, suited for heavy loads and longevity. | Durable but dependent on module connection integrity. |

| Use Cases | Complex structures, large-scale projects requiring bespoke features. | Residential, hotels, schools, rapid-deployment buildings. |

Understanding CMF Structure: Definition and Components

CMF structure, or Cladding, Mulls, and Framing, refers to the integrated system of exterior building components that provide both structural support and aesthetic finish. These components include panels, mullions, and framing elements designed for easy assembly, durability, and flexibility in architectural design. Understanding CMF structure helps you optimize building performance and streamline installation compared to traditional modular construction methods.

What is Modular Construction? Key Features Explained

Modular construction is a process that involves fabricating building components in a controlled factory environment, which are then transported and assembled on-site, enhancing efficiency and reducing construction time. Key features include standardized modules, precision manufacturing, minimized on-site disruption, and improved quality control due to factory conditions. This method contrasts with CMF (Color, Material, Finish) structure approaches by emphasizing repeatable, scalable building units rather than purely aesthetic or material considerations.

CMF Structure vs Modular Construction: Fundamental Differences

CMF structure relies on a load-bearing concrete, masonry, and framing system offering durability and fire resistance, ideal for heavy structural demands. Modular construction involves pre-fabricated sections assembled on-site, significantly reducing construction time and labor costs while enhancing quality control. Your choice between CMF structure and modular construction depends on project scope, budget, and timeline priorities.

Material Selection in CMF and Modular Approaches

Material selection in CMF (Color, Material, Finish) structure emphasizes aesthetic consistency and sensory appeal, prioritizing surface textures, hues, and tactile qualities to enhance user experience. Modular construction, by contrast, focuses on standardized, prefabricated components that prioritize durability, structural integrity, and ease of assembly, often utilizing materials like steel, concrete, and engineered wood. Your choice between CMF and modular approaches depends on whether visual customization or construction efficiency and scalability are the primary project goals.

Speed and Efficiency: Comparing Project Timelines

CMF (Component, Material, Finishes) structure significantly reduces project timelines by integrating prefabricated elements optimized for rapid assembly, contrasting with modular construction where entire modules are built off-site and require transportation logistics. The precision of CMF components allows faster on-site installation and fewer coordination delays, enhancing overall efficiency. Modular construction benefits from parallel site and factory work but often faces extended timelines due to module delivery and crane scheduling constraints.

Cost Implications: Which Method is More Economical?

Modular construction typically reduces overall costs by enabling faster project completion and lower labor expenses due to factory-controlled settings. CMF (Concrete, Masonry, and Frame) structures often incur higher site labor costs and longer timelines, increasing the total expenditure. Your choice should weigh initial investment against long-term savings, with modular construction generally offering more economical benefits for time-sensitive projects.

Sustainability and Environmental Impact Analysis

CMF structure integrates materials and finishes in a cohesive system that reduces waste and enhances energy efficiency, promoting sustainable building practices. Modular construction significantly minimizes environmental impact by offsite manufacturing, reducing site disturbance, energy consumption, and material waste during assembly. You can achieve higher sustainability goals by combining CMF strategies with modular construction methods, optimizing resource use and lowering the overall carbon footprint.

Flexibility and Adaptability in Design

CMF (Color, Material, Finish) structure offers superior flexibility by allowing designers to easily modify aesthetic elements without altering the underlying architecture, enabling rapid customization and personalization. Modular construction focuses on adaptability through pre-fabricated components that can be reconfigured or expanded efficiently, promoting scalable and repeatable design solutions. Combining CMF strategies with modular construction enhances overall design adaptability, streamlining both visual updates and structural modifications in dynamic environments.

Real-World Applications: Case Studies and Examples

Case studies reveal that CMF (Color, Material, Finish) structures enhance modular construction by enabling tailored aesthetic and functional outcomes in projects like automotive interiors and consumer electronics. Companies leveraging CMF strategies in modular builds report improved user engagement and streamlined manufacturing processes, evidenced by brands such as Tesla and IKEA implementing customizable panels and finishes. Your next modular construction project can benefit significantly from integrating CMF principles to boost both design flexibility and market appeal.

Future Trends in CMF Structure and Modular Construction

Future trends in CMF structure emphasize enhanced integration of advanced materials like ultra-high performance concrete and smart composites to improve durability and sustainability. Modular construction is shifting towards greater automation and digitalization, incorporating Building Information Modeling (BIM) and prefabricated, standardized units to accelerate project timelines and reduce waste. Hybrid approaches combining CMF structural components with modular techniques are emerging, enabling scalable, resilient, and cost-effective building solutions for urban development and disaster relief.

CMF structure vs modular construction Infographic

libmatt.com

libmatt.com