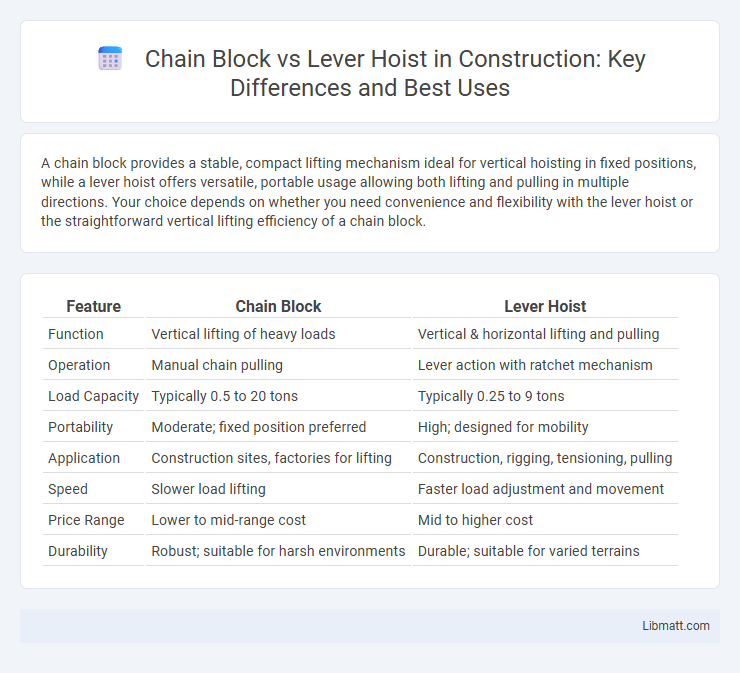

A chain block provides a stable, compact lifting mechanism ideal for vertical hoisting in fixed positions, while a lever hoist offers versatile, portable usage allowing both lifting and pulling in multiple directions. Your choice depends on whether you need convenience and flexibility with the lever hoist or the straightforward vertical lifting efficiency of a chain block.

Table of Comparison

| Feature | Chain Block | Lever Hoist |

|---|---|---|

| Function | Vertical lifting of heavy loads | Vertical & horizontal lifting and pulling |

| Operation | Manual chain pulling | Lever action with ratchet mechanism |

| Load Capacity | Typically 0.5 to 20 tons | Typically 0.25 to 9 tons |

| Portability | Moderate; fixed position preferred | High; designed for mobility |

| Application | Construction sites, factories for lifting | Construction, rigging, tensioning, pulling |

| Speed | Slower load lifting | Faster load adjustment and movement |

| Price Range | Lower to mid-range cost | Mid to higher cost |

| Durability | Robust; suitable for harsh environments | Durable; suitable for varied terrains |

Introduction to Chain Blocks and Lever Hoists

Chain blocks and lever hoists are essential lifting devices used in material handling and construction industries. Chain blocks use a system of chain loops and a gear mechanism to lift heavy loads vertically, providing precise load control and high load capacity. Lever hoists operate with a ratcheting lever arm to lift or pull loads horizontally or vertically, offering greater maneuverability and ease of use in confined spaces.

Key Differences Between Chain Blocks and Lever Hoists

Chain blocks offer vertical lifting through a hand-operated chain mechanism, ideal for stationary lifting tasks with heavier loads up to several tons. Lever hoists provide both lifting and pulling capabilities, featuring a ratcheting lever for precise load positioning and greater maneuverability in confined spaces. The main differences lie in their operation method, load control precision, and suitability for vertical lifting versus horizontal pulling applications.

How Chain Blocks Work: Mechanism and Uses

Chain blocks operate using a system of gears and a hand chain to lift heavy loads by converting manual force into mechanical advantage, allowing precise control and increased lifting capacity. The internal mechanism consists of a toothed wheel and pawl system that locks the load in place, ensuring safety during lifting or lowering operations. You can find chain blocks commonly used in construction, manufacturing, and maintenance tasks where stable, vertical lifting is essential.

How Lever Hoists Operate: Functionality and Applications

Lever hoists operate by using a ratcheting lever to move a chain through a lifting mechanism, allowing precise control of load lifting, lowering, and tensioning. Their compact, portable design makes them ideal for applications requiring manual lifting in confined spaces or on uneven surfaces, such as construction, maintenance, and rigging tasks. You can rely on lever hoists for versatile functionality where controlled, incremental load movement is essential.

Load Capacity Comparison: Chain Block vs Lever Hoist

Chain blocks typically offer higher load capacities, often handling weights from 0.5 to 20 tons, making them ideal for heavy lifting in industrial settings. Lever hoists generally support lighter loads, usually ranging from 0.25 to 6 tons, suitable for more precise or smaller scale lifting tasks. Your choice between the two should depend on the required load capacity and the specific lifting application.

Safety Features of Chain Blocks and Lever Hoists

Chain blocks incorporate robust braking systems designed to prevent load slippage, ensuring secure lifting and lowering operations. Lever hoists feature overload protection mechanisms and automatic load-holding brakes, enhancing user safety during tensioning and pulling tasks. Both devices are engineered with durable, high-strength alloy steel components to withstand heavy-duty use and maintain operational integrity.

Advantages of Using Chain Blocks

Chain blocks offer significant load capacity suited for heavy lifting tasks, providing enhanced durability with robust steel construction and corrosion-resistant coatings. Their efficient mechanical advantage enables precise control and minimal effort, reducing operator fatigue during extended use. Chain blocks also feature versatile mounting options and low maintenance requirements, making them ideal for industrial environments and rigorous applications.

Benefits of Lever Hoists in Material Handling

Lever hoists offer precise load control and increased versatility in material handling due to their ability to operate in tight spaces and at various angles. Their compact design and manual operation ensure ease of use without the need for power sources, making them ideal for remote or confined job sites. Enhanced safety features such as load braking and overload protection improve operational reliability compared to standard chain blocks.

Choosing the Right Hoist for Your Needs

Selecting the right hoist depends on the load capacity and application requirements; chain blocks are ideal for heavy, stationary lifting with high load capacities, offering robust durability and precise control. Lever hoists provide greater mobility and versatility for lifting, pulling, and tensioning in confined spaces or uneven terrain due to their compact design and adjustable load tension. Evaluating factors such as lifting height, frequency of use, and environmental conditions ensures optimal efficiency and safety in your lifting operations.

Maintenance Tips for Chain Blocks and Lever Hoists

Regular inspection of chain blocks and lever hoists ensures safe operation by identifying wear, corrosion, and damaged components early; lubricate chains and moving parts with manufacturer-recommended oils to prevent rust and maintain smooth functionality. Cleaning after use, especially in dusty or wet environments, prolongs equipment life by avoiding buildup that can hinder performance. Store both tools in dry, secure locations to protect against environmental damage and perform load chain replacements as per usage hours specified in the equipment manual.

Chain block vs lever hoist Infographic

libmatt.com

libmatt.com