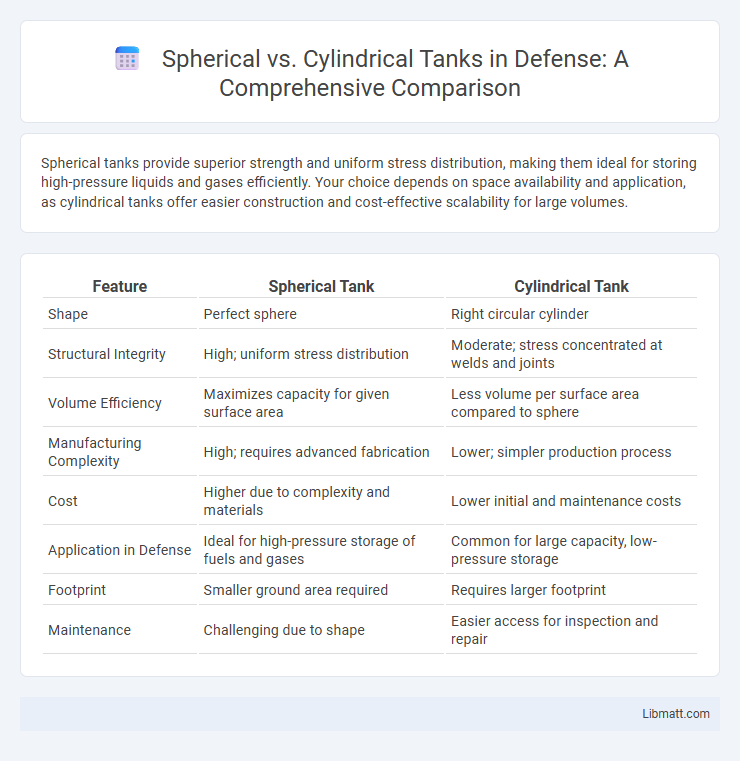

Spherical tanks provide superior strength and uniform stress distribution, making them ideal for storing high-pressure liquids and gases efficiently. Your choice depends on space availability and application, as cylindrical tanks offer easier construction and cost-effective scalability for large volumes.

Table of Comparison

| Feature | Spherical Tank | Cylindrical Tank |

|---|---|---|

| Shape | Perfect sphere | Right circular cylinder |

| Structural Integrity | High; uniform stress distribution | Moderate; stress concentrated at welds and joints |

| Volume Efficiency | Maximizes capacity for given surface area | Less volume per surface area compared to sphere |

| Manufacturing Complexity | High; requires advanced fabrication | Lower; simpler production process |

| Cost | Higher due to complexity and materials | Lower initial and maintenance costs |

| Application in Defense | Ideal for high-pressure storage of fuels and gases | Common for large capacity, low-pressure storage |

| Footprint | Smaller ground area required | Requires larger footprint |

| Maintenance | Challenging due to shape | Easier access for inspection and repair |

Introduction: Overview of Spherical and Cylindrical Tanks

Spherical tanks offer superior strength and uniform stress distribution due to their curved shape, making them ideal for storing high-pressure gases and liquids. Cylindrical tanks, characterized by their simple geometry and ease of fabrication, are commonly used for both vertical and horizontal storage of liquids and gases in various industries. Material efficiency and pressure resistance mark key differences, with spherical tanks minimizing surface area for volume compared to cylindrical tanks.

Design Principles of Spherical Tanks

Spherical tanks maximize structural integrity by evenly distributing stress across their curved surface, minimizing the material needed while withstanding high internal pressures efficiently. The spherical design eliminates stress concentration points, resulting in thinner walls compared to cylindrical tanks of similar capacity, which reduces weight and construction costs. This shape is particularly advantageous for storing gases or liquids under pressure, as it balances mechanical strength and material economy effectively.

Design Principles of Cylindrical Tanks

Cylindrical tanks are designed based on principles that optimize structural efficiency and material use, featuring uniform stress distribution along their curved surfaces to withstand internal pressure. The flat circular ends combined with a cylindrical body allow for easier fabrication and scalable volume capacity, making them ideal for storing liquids and gases under moderate pressure. Your choice of a cylindrical tank leverages its straightforward design, enabling cost-effective manufacturing and maintenance compared to more complex geometries like spherical tanks.

Material Requirements and Construction Methods

Spherical tanks require less material than cylindrical tanks to store the same volume due to their minimized surface area, resulting in cost-efficient construction. The fabrication of spherical tanks involves complex welding and assembly techniques, often requiring specialized equipment, whereas cylindrical tanks are easier to manufacture with standard rolling and welding methods. Your choice between these tanks should consider the balance between material savings and the complexity of construction processes.

Space Efficiency and Footprint Comparison

Spherical tanks offer superior space efficiency by enclosing the maximum volume with the minimum surface area, resulting in a smaller footprint compared to cylindrical tanks. Cylindrical tanks require more ground area due to their elongated shape and larger surface area for the same storage capacity. This makes spherical tanks ideal for facilities with limited space or where minimizing ground use is critical.

Structural Strength and Pressure Handling

Spherical tanks exhibit superior structural strength due to their uniform stress distribution, allowing them to handle higher internal pressures with less material thickness compared to cylindrical tanks. The geometric shape of spherical tanks minimizes stress concentration points, enhancing their resistance to deformation under pressure. Cylindrical tanks, while easier to manufacture, require additional reinforcement such as stiffening rings to safely withstand similar pressure levels.

Cost Analysis: Initial Investment and Maintenance

Spherical tanks generally have a higher initial investment due to complex fabrication and specialized materials required for their curved surfaces, but they offer lower maintenance costs because their shape evenly distributes stress and reduces corrosion points. Cylindrical tanks, while cheaper to construct initially due to simpler design and standardized components, may incur higher maintenance expenses over time as they experience uneven stress distribution and potential weld joint weaknesses. Choosing between the two depends on weighing upfront manufacturing costs against long-term upkeep efficiency and durability.

Applications and Industry Preferences

Spherical tanks are preferred in industries requiring high-pressure storage such as petrochemical, liquefied natural gas (LNG), and gas processing due to their ability to evenly distribute stress and minimize material usage. Cylindrical tanks dominate applications in water treatment, agriculture, and oil storage because of their simpler design, ease of construction, and suitability for low-pressure storage. Your choice depends on specific requirements like pressure tolerance, space constraints, and cost-efficiency within your industry.

Safety Considerations for Each Tank Type

Spherical tanks offer superior safety due to their uniform stress distribution, reducing the risk of structural failure under high pressure and minimizing explosion hazards. Cylindrical tanks, while easier to manufacture and inspect, may experience uneven stress concentrations, especially at the cylindrical-to-head junctions, increasing vulnerability to leaks or ruptures. Your choice should factor in the specific safety requirements of the stored material, as spherical tanks are preferred for high-pressure gases, whereas cylindrical tanks are commonly used for liquids with lower pressure conditions.

Conclusion: Choosing the Right Tank for Your Needs

Spherical tanks offer superior strength and pressure resistance due to their uniform stress distribution, making them ideal for storing high-pressure gases and large volumes efficiently. Cylindrical tanks provide easier manufacturing, installation, and maintenance, often preferred for liquid storage and applications requiring modular designs. Selecting the right tank depends on factors such as storage capacity, pressure requirements, installation space, and budget constraints to ensure optimal performance and cost-effectiveness.

Spherical tank vs Cylindrical tank Infographic

libmatt.com

libmatt.com