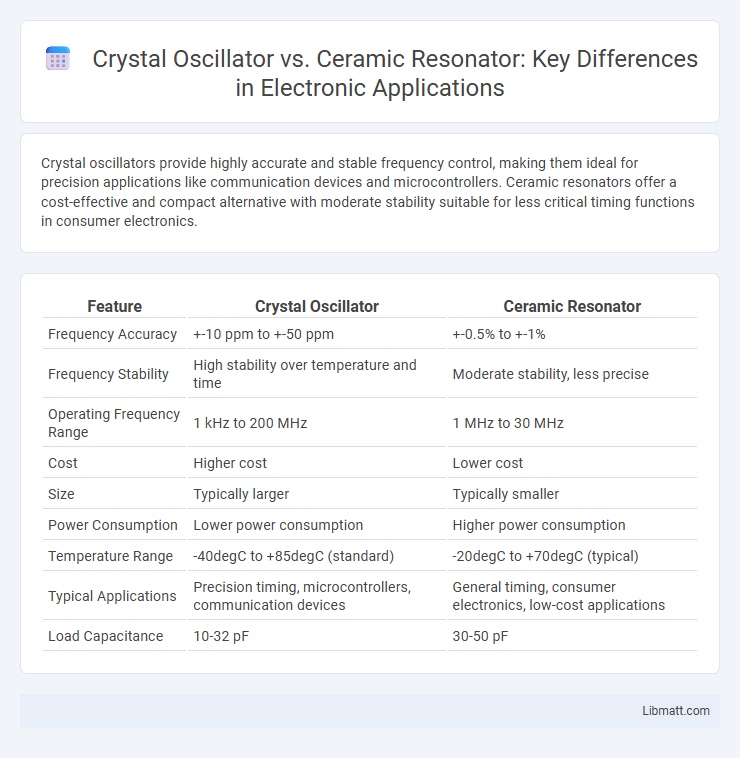

Crystal oscillators provide highly accurate and stable frequency control, making them ideal for precision applications like communication devices and microcontrollers. Ceramic resonators offer a cost-effective and compact alternative with moderate stability suitable for less critical timing functions in consumer electronics.

Table of Comparison

| Feature | Crystal Oscillator | Ceramic Resonator |

|---|---|---|

| Frequency Accuracy | +-10 ppm to +-50 ppm | +-0.5% to +-1% |

| Frequency Stability | High stability over temperature and time | Moderate stability, less precise |

| Operating Frequency Range | 1 kHz to 200 MHz | 1 MHz to 30 MHz |

| Cost | Higher cost | Lower cost |

| Size | Typically larger | Typically smaller |

| Power Consumption | Lower power consumption | Higher power consumption |

| Temperature Range | -40degC to +85degC (standard) | -20degC to +70degC (typical) |

| Typical Applications | Precision timing, microcontrollers, communication devices | General timing, consumer electronics, low-cost applications |

| Load Capacitance | 10-32 pF | 30-50 pF |

Introduction to Crystal Oscillators and Ceramic Resonators

Crystal oscillators and ceramic resonators are essential components used to generate precise frequency signals in electronic circuits. Crystal oscillators utilize quartz crystals to provide high stability and accuracy, making them ideal for applications requiring tight frequency control. Ceramic resonators, composed of piezoelectric ceramic materials, offer cost-effective solutions with moderate frequency stability suited for less demanding timing applications.

Basic Structure and Operating Principles

Crystal oscillators use a quartz crystal with precise cut angles to generate a stable frequency through the piezoelectric effect, where mechanical vibrations convert to electrical signals. Ceramic resonators consist of piezoelectric ceramic materials that vibrate at specific frequencies but provide less frequency stability and accuracy compared to crystal oscillators. Your choice depends on whether you prioritize high frequency precision or cost-effective, moderate stability performance.

Frequency Stability Comparison

Crystal oscillators offer superior frequency stability compared to ceramic resonators, with typical frequency tolerances as low as +-10 ppm and aging rates around +-1 ppm per year. Ceramic resonators generally exhibit lower frequency stability, having tolerances between +-0.1% to +-0.5% and higher sensitivity to temperature variations and aging. This makes crystal oscillators the preferred choice for applications requiring precise and stable clock frequencies over time.

Accuracy and Precision Differences

Crystal oscillators offer superior accuracy and precision compared to ceramic resonators, with typical frequency stability within +-20 ppm and low phase noise suitable for high-frequency applications. Ceramic resonators provide moderate accuracy, usually around +-0.5% frequency tolerance, making them acceptable for cost-sensitive, less demanding timing circuits. The inherent material properties of quartz crystals enable crystal oscillators to maintain consistent oscillation frequencies over temperature variations, whereas ceramic resonators exhibit greater drift and jitter.

Cost and Availability

Crystal oscillators generally offer higher precision but come at a higher cost compared to ceramic resonators, making them less affordable for budget-sensitive projects. Ceramic resonators are widely available and cost-effective, often preferred in consumer electronics where moderate frequency stability suffices. The cost-efficiency and abundant availability of ceramic resonators contribute to their popularity in mass-produced devices.

Size and Packaging Options

Crystal oscillators typically offer smaller sizes and more compact packaging options compared to ceramic resonators, making them ideal for space-constrained applications. Packaging choices for crystal oscillators often include surface-mount and through-hole formats, with metal or ceramic enclosures enhancing frequency stability. Ceramic resonators usually come in larger, less compact packages, primarily using through-hole mounts, which can limit their integration into miniaturized electronic devices.

Power Consumption Considerations

Crystal oscillators typically exhibit lower power consumption due to their high Q-factor, making them ideal for battery-powered or energy-sensitive applications. Ceramic resonators, while generally consuming slightly more power, offer cost-effective frequency stability suitable for less demanding power constraints. Your choice between these components should balance power budget requirements with frequency accuracy and device complexity.

Common Applications and Use Cases

Crystal oscillators are widely used in high-precision applications such as communication systems, microcontrollers, and timing devices due to their superior frequency stability and accuracy. Ceramic resonators find common use in cost-sensitive consumer electronics, automotive controls, and simple timing circuits where moderate frequency accuracy is sufficient. Both components are essential in embedded systems, with crystal oscillators preferred for critical timing and ceramic resonators for budget-friendly, less demanding applications.

Advantages and Disadvantages

Crystal oscillators offer high frequency stability and precision due to their quartz crystal's consistent oscillation, making them ideal for applications requiring accurate timing. Ceramic resonators, while less precise, provide cost-effective and robust alternatives with faster start-up times and better vibration resistance. Your choice depends on whether you prioritize accuracy and stability (crystal oscillators) or lower cost and durability (ceramic resonators).

Selecting the Right Component for Your Project

Selecting the right component for your project depends on the required frequency stability and cost constraints, with crystal oscillators offering superior precision and lower phase noise compared to ceramic resonators. Ceramic resonators provide a cost-effective solution for applications tolerant to moderate frequency drift and less stringent timing requirements. Your choice should align with the balance between performance needs and budget limitations to ensure optimal circuit functionality.

Crystal Oscillator vs Ceramic Resonator Infographic

libmatt.com

libmatt.com