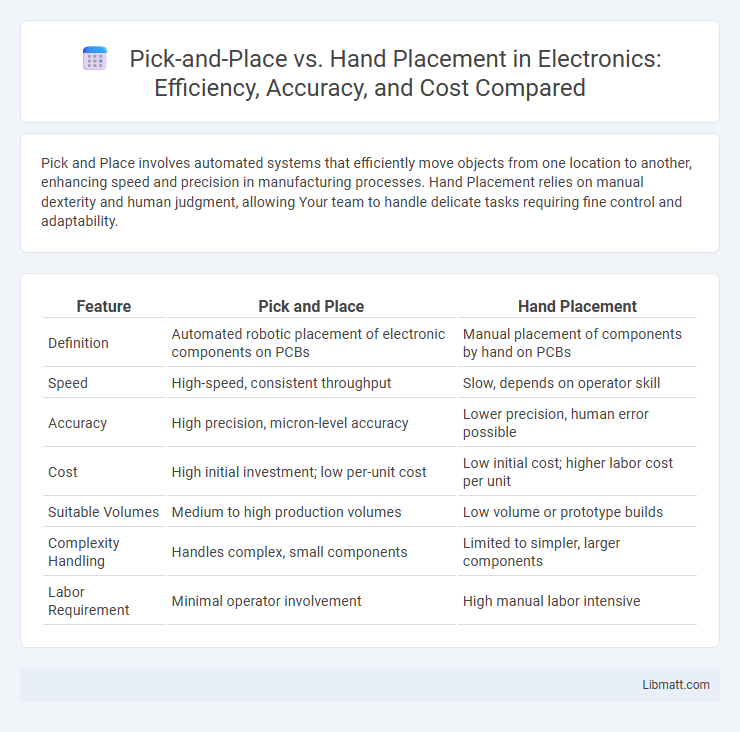

Pick and Place involves automated systems that efficiently move objects from one location to another, enhancing speed and precision in manufacturing processes. Hand Placement relies on manual dexterity and human judgment, allowing Your team to handle delicate tasks requiring fine control and adaptability.

Table of Comparison

| Feature | Pick and Place | Hand Placement |

|---|---|---|

| Definition | Automated robotic placement of electronic components on PCBs | Manual placement of components by hand on PCBs |

| Speed | High-speed, consistent throughput | Slow, depends on operator skill |

| Accuracy | High precision, micron-level accuracy | Lower precision, human error possible |

| Cost | High initial investment; low per-unit cost | Low initial cost; higher labor cost per unit |

| Suitable Volumes | Medium to high production volumes | Low volume or prototype builds |

| Complexity Handling | Handles complex, small components | Limited to simpler, larger components |

| Labor Requirement | Minimal operator involvement | High manual labor intensive |

Introduction to Pick and Place vs Hand Placement

Pick and Place machines automate the precise transfer of components onto PCBs using robotic arms and vision systems, significantly enhancing efficiency in electronics manufacturing. Hand Placement involves manual component placement by operators, offering flexibility for small production runs or prototyping but with lower speed and consistency. Comparing Pick and Place vs Hand Placement highlights the trade-off between automation speed and manual adaptability in assembly processes.

Defining Pick and Place Technology

Pick and Place technology automates the precise movement of components from one location to another using robotic arms and specialized grippers, often employed in electronics manufacturing for rapid assembly processes. This system enhances accuracy and speed compared to Hand Placement, where operators manually place components, increasing the risk of human error and slower throughput. Understanding this distinction helps you optimize production efficiency and maintain consistent quality in your manufacturing workflow.

Understanding Hand Placement Methods

Hand placement methods involve manually positioning components on a circuit board, requiring precision and steady hands for effective assembly. These techniques are essential for prototypes, small batches, or complex parts unsuitable for automated machines. Understanding the nuances of hand placement helps you improve accuracy and reduce the risk of damage during electronic manufacturing.

Key Differences Between Automation and Manual Placement

Pick and Place machines use robotic arms and vision systems to accurately handle components, offering high speed and consistent precision in assembly lines, whereas hand placement relies on human dexterity and judgment, resulting in slower throughput and variable accuracy. Automation minimizes errors and increases production scalability by maintaining exact repeatability, while manual placement is limited by individual skill and fatigue, impacting efficiency. The decision between automation and manual methods hinges on production volume, complexity, and cost-effectiveness.

Efficiency and Speed: A Comparative Analysis

Pick and Place machines outperform Hand Placement in efficiency and speed by automating component positioning with high precision, drastically reducing cycle times and human error. Hand Placement relies on manual labor, which introduces variability and slower throughput, especially in large-scale manufacturing. Automation with Pick and Place enhances production rates and consistency, making it the preferred choice for modern electronics assembly lines.

Accuracy and Precision in Assembly Processes

Pick and Place machines offer superior accuracy and precision in assembly processes due to advanced robotics and automated positioning systems, minimizing human error. Hand placement, while flexible for delicate or complex components, often lacks consistent precision and can lead to variability in assembly quality. Your production efficiency improves significantly when using pick and place technology for tasks demanding high repeatability and exact component placement.

Cost Implications: Upfront vs Long-Term Expenses

Pick and Place machines require a significant upfront investment in automation technology, but they reduce long-term labor costs through increased speed and precision. Hand placement involves lower initial expenses, as manual labor does not require costly equipment, but ongoing labor costs and consistency issues can drive higher total expenses over time. Evaluating total cost of ownership reveals that automated pick and place often leads to greater cost efficiency in large-scale production despite higher initial capital outlays.

Flexibility and Versatility in Manufacturing

Pick and Place machines offer high flexibility and versatility in manufacturing by efficiently handling various components with precise speed and repeatability, making them ideal for mass production. Hand placement provides unmatched adaptability for complex or delicate tasks where human judgment and dexterity are crucial, allowing customization for small batches or intricate assemblies. Combining both methods enhances overall manufacturing efficiency by balancing automation speed with skilled manual adjustments.

Safety Considerations for Workforce and Equipment

Pick and Place machines reduce repetitive strain injuries and physical fatigue by automating component handling, enhancing safety for your workforce. Hand placement increases the risk of ergonomic hazards and potential contamination, which can compromise both product quality and operator health. Equipment safety improves with automated systems featuring built-in sensors and fail-safes, minimizing accidental damage and ensuring consistent handling.

Choosing the Right Method for Your Production Needs

Pick and Place machines offer high-speed, precise component placement ideal for large-scale, automated PCB assembly, while hand placement provides flexibility and control suited for small batches or prototypes. Evaluating production volume, component complexity, and budget constraints helps determine the most efficient method. Selecting the appropriate technique optimizes manufacturing efficiency and ensures product quality.

Pick and Place vs Hand Placement Infographic

libmatt.com

libmatt.com