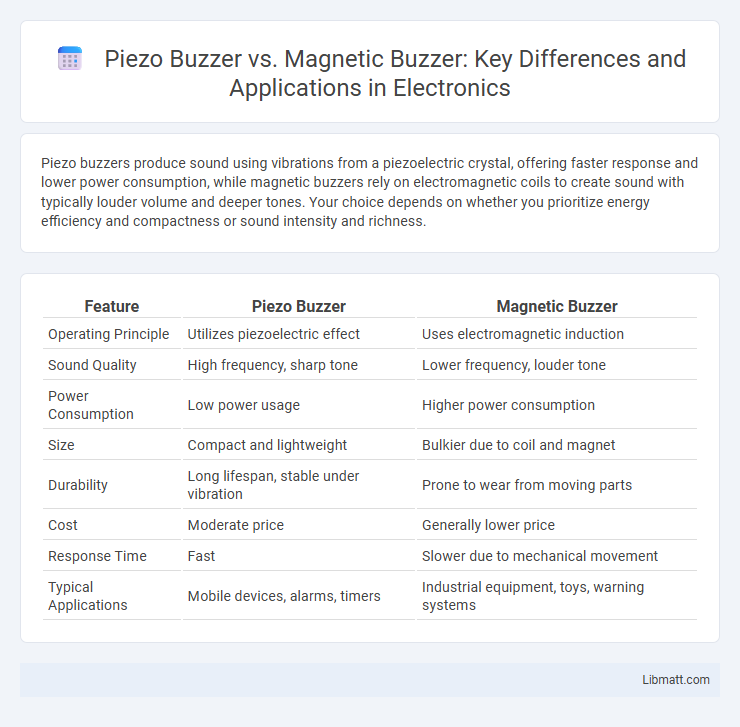

Piezo buzzers produce sound using vibrations from a piezoelectric crystal, offering faster response and lower power consumption, while magnetic buzzers rely on electromagnetic coils to create sound with typically louder volume and deeper tones. Your choice depends on whether you prioritize energy efficiency and compactness or sound intensity and richness.

Table of Comparison

| Feature | Piezo Buzzer | Magnetic Buzzer |

|---|---|---|

| Operating Principle | Utilizes piezoelectric effect | Uses electromagnetic induction |

| Sound Quality | High frequency, sharp tone | Lower frequency, louder tone |

| Power Consumption | Low power usage | Higher power consumption |

| Size | Compact and lightweight | Bulkier due to coil and magnet |

| Durability | Long lifespan, stable under vibration | Prone to wear from moving parts |

| Cost | Moderate price | Generally lower price |

| Response Time | Fast | Slower due to mechanical movement |

| Typical Applications | Mobile devices, alarms, timers | Industrial equipment, toys, warning systems |

Introduction to Buzzers: Piezo vs Magnetic

Piezo buzzers utilize the piezoelectric effect to convert electrical signals into sound through a vibrating ceramic element, providing high-frequency tones with low power consumption ideal for compact electronic devices. Magnetic buzzers operate using an electromagnet and a metallic diaphragm, producing louder, lower-frequency sounds often employed in industrial alarms and automotive applications. Choosing between a piezo or magnetic buzzer depends on your need for volume, tone quality, and power efficiency in your project.

Understanding How Piezo Buzzers Work

Piezo buzzers operate by applying an alternating voltage to a piezoelectric ceramic disc, causing it to vibrate and produce sound waves through mechanical deformation. This precise vibration allows piezo buzzers to generate high-frequency tones with low power consumption and a compact design. Your choice of a piezo buzzer ensures reliable, sharp audio signals ideal for alarms, timers, and feedback devices.

How Magnetic Buzzers Operate

Magnetic buzzers operate by utilizing an electromagnet that creates a magnetic field when current passes through a coil, causing a diaphragm to vibrate and produce sound. Unlike piezo buzzers, which rely on the deformation of piezoelectric materials, magnetic buzzers depend on the interaction between the coil's magnetic field and a metal diaphragm to generate audible signals. Understanding how magnetic buzzers function helps you choose the right component for applications requiring distinct sound frequencies and louder volume output.

Key Differences Between Piezo and Magnetic Buzzers

Piezo buzzers operate using the piezoelectric effect, offering fast response times and higher frequency ranges ideal for precise audio signals, while magnetic buzzers rely on electromagnetic coils to produce sound, generally providing louder volumes at lower frequencies. Piezo buzzers consume less power and are more durable due to their solid-state construction, whereas magnetic buzzers tend to be bulkier and require more current. Understanding these key differences helps you select the right buzzer type based on your device's size, power constraints, and audio requirements.

Sound Quality Comparison: Piezo vs Magnetic

Piezo buzzers deliver clear, high-frequency tones with minimal distortion, making them ideal for precise audio signaling in medical devices and alarms. Magnetic buzzers produce a richer, louder sound with lower frequency range suitable for general notifications and larger environments. Sound quality in piezo buzzers excels in tonal accuracy, while magnetic buzzers prioritize volume and bass response.

Power Consumption and Efficiency

Piezo buzzers consume significantly less power than magnetic buzzers, making them ideal for battery-operated devices where energy efficiency is critical. Your choice of buzzer impacts overall system performance, as piezo models convert electrical energy directly into sound with higher efficiency, reducing power loss. Magnetic buzzers, while louder at lower voltages, typically draw higher current, resulting in increased power consumption and lower efficiency in continuous use.

Size, Design, and Mounting Options

Piezo buzzers are typically smaller and more compact than magnetic buzzers, making them ideal for applications with limited space. Their solid-state design allows for a variety of mounting options, including surface-mount technology (SMT) and through-hole configurations, providing flexibility in PCB integration. Your choice between piezo and magnetic buzzers should consider the size constraints and mounting preferences of your specific project.

Applications and Use Cases

Piezo buzzers are widely used in compact electronic devices such as alarms, timers, and medical instruments due to their low power consumption and fast response time. Magnetic buzzers excel in automotive, industrial, and consumer electronics applications where louder sound output and higher durability are required. Both types serve critical roles in alerting systems, with piezo buzzers favored for precision and magnetic buzzers chosen for robust, high-volume signaling.

Pros and Cons of Piezo Buzzers

Piezo buzzers offer advantages such as low power consumption, high-frequency sound production, and long lifespan due to solid-state construction, making them ideal for compact and energy-efficient devices. However, their sound output is generally less loud compared to magnetic buzzers and can be more expensive to produce at scale. Piezo buzzers also have limited tonal variety and may require additional circuitry to achieve desired sound patterns.

Pros and Cons of Magnetic Buzzers

Magnetic buzzers offer high sound output and robust performance at a relatively low cost, making them ideal for applications requiring loud alerts. Their coil-based design, however, results in higher power consumption and slower response times compared to piezo buzzers. Magnetic buzzers are also bulkier and less resistant to environmental factors such as temperature and humidity, which can limit their use in harsh conditions.

Piezo Buzzer vs Magnetic Buzzer Infographic

libmatt.com

libmatt.com