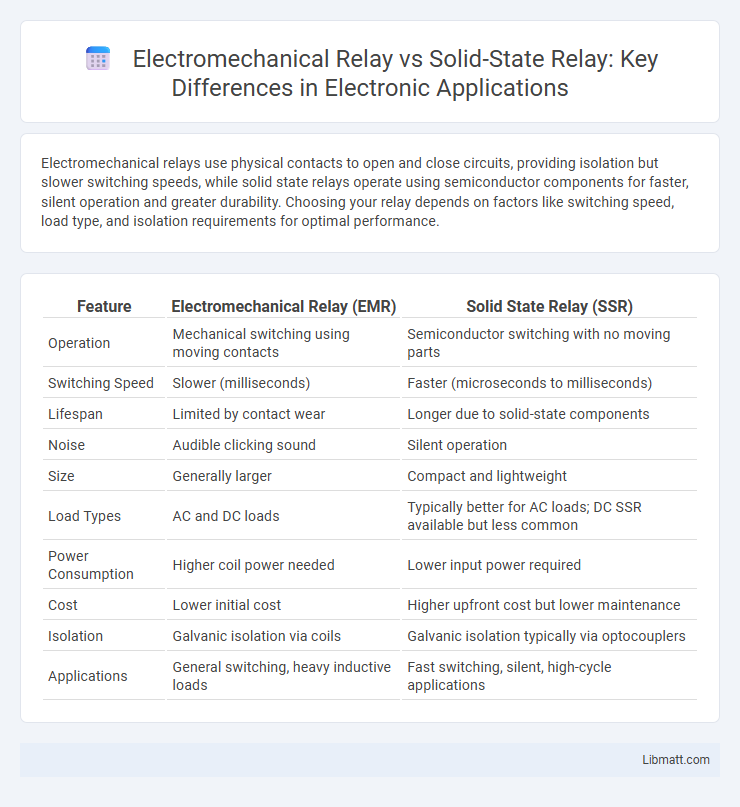

Electromechanical relays use physical contacts to open and close circuits, providing isolation but slower switching speeds, while solid state relays operate using semiconductor components for faster, silent operation and greater durability. Choosing your relay depends on factors like switching speed, load type, and isolation requirements for optimal performance.

Table of Comparison

| Feature | Electromechanical Relay (EMR) | Solid State Relay (SSR) |

|---|---|---|

| Operation | Mechanical switching using moving contacts | Semiconductor switching with no moving parts |

| Switching Speed | Slower (milliseconds) | Faster (microseconds to milliseconds) |

| Lifespan | Limited by contact wear | Longer due to solid-state components |

| Noise | Audible clicking sound | Silent operation |

| Size | Generally larger | Compact and lightweight |

| Load Types | AC and DC loads | Typically better for AC loads; DC SSR available but less common |

| Power Consumption | Higher coil power needed | Lower input power required |

| Cost | Lower initial cost | Higher upfront cost but lower maintenance |

| Isolation | Galvanic isolation via coils | Galvanic isolation typically via optocouplers |

| Applications | General switching, heavy inductive loads | Fast switching, silent, high-cycle applications |

Introduction to Relays: Electromechanical vs Solid State

Electromechanical relays use physical moving parts to open or close electrical contacts, providing high isolation and durability in switching high voltages and currents. Solid state relays rely on semiconductor components like thyristors or transistors, offering faster switching speeds, silent operation, and longer lifespan due to the absence of mechanical wear. Your choice between electromechanical and solid state relays depends on factors such as load type, switching frequency, and environmental conditions.

Fundamental Working Principles

Electromechanical relays operate using an electromagnetic coil that physically moves contacts to open or close a circuit, providing isolation between input and output. Solid state relays use semiconductor devices, such as thyristors or transistors, to switch circuits electronically without moving parts, resulting in faster response times and increased durability. Your choice depends on whether mechanical isolation or rapid, silent switching is more critical for your application.

Key Differences Between Electromechanical and Solid State Relays

Electromechanical relays use physical moving parts to open or close circuits, providing mechanical isolation but slower switching speeds and limited lifespan due to wear. Solid state relays incorporate semiconductor components, offering faster switching, longer durability, and resistance to shock and vibration, while lacking the mechanical isolation of electromechanical types. Key differences include response time, durability, noise generation, and suitability for high-frequency switching applications.

Performance and Switching Speed Comparison

Electromechanical relays typically have slower switching speeds, averaging 5 to 20 milliseconds, due to their mechanical moving parts, while solid-state relays offer rapid switching times in the microseconds range, enhancing performance in high-speed applications. The absence of mechanical wear in solid-state relays results in longer operational lifespans and more reliable switching under frequent cycles. Choosing a solid-state relay can improve your system's efficiency by minimizing signal delay and enhancing overall response time.

Durability and Lifecycle Analysis

Electromechanical relays typically offer a lifecycle ranging from 100,000 to 10 million operations due to their mechanical contacts subject to wear and tear, impacting durability over time. Solid state relays (SSRs) provide superior durability with lifecycles exceeding 100 million operations as they rely on semiconductor components with no physical contacts to degrade. Your choice between electromechanical and solid state relays should consider the application's switching frequency and environmental conditions to optimize durability and overall lifecycle performance.

Application Suitability in Modern Systems

Electromechanical relays are suited for applications requiring high current switching and electrical isolation, commonly found in industrial machines and heavy-duty equipment. Solid state relays excel in fast switching, low noise, and long-life durability, making them ideal for automation, heating elements, and sensitive electronics in modern systems. Your choice depends on factors like switching speed, load type, and required reliability for optimal application performance.

Advantages of Electromechanical Relays

Electromechanical relays offer the advantage of physical isolation between input and output circuits, providing high voltage and current switching capabilities with minimal leakage current. They excel in handling inductive loads and are less sensitive to voltage spikes, resulting in greater durability in harsh electrical environments. Their clear mechanical operation allows easy visual status confirmation and straightforward diagnostic testing.

Benefits of Solid State Relays

Solid State Relays (SSRs) offer superior durability and longer operational life due to their lack of moving parts, reducing wear and mechanical failure risks compared to Electromechanical Relays (EMRs). They provide faster switching speeds and silent operation, making them ideal for applications requiring precision and noise reduction. Your system benefits from enhanced reliability, reduced electromagnetic interference, and lower power consumption with SSRs.

Cost Considerations and Long-Term Value

Electromechanical relays generally have lower upfront costs but require more maintenance due to mechanical wear, impacting long-term expenses. Solid state relays, while initially pricier, offer longer operational life, faster switching, and reduced maintenance, delivering better value over time. Your choice should weigh initial budget constraints against reliability and total cost of ownership for optimal cost-effectiveness.

Choosing the Right Relay for Your Application

When choosing the right relay for your application, consider the switching speed and durability requirements; electromechanical relays offer robust physical contact and higher current capacity but have slower switching speeds, while solid state relays provide faster, quieter operation with no mechanical wear. Your decision should also factor in electrical noise sensitivity and load type, as solid state relays excel in low-noise environments and sensitive electronic circuits. Assessing these performance characteristics ensures optimal reliability and efficiency in your control systems.

Electromechanical vs Solid State Relay Infographic

libmatt.com

libmatt.com