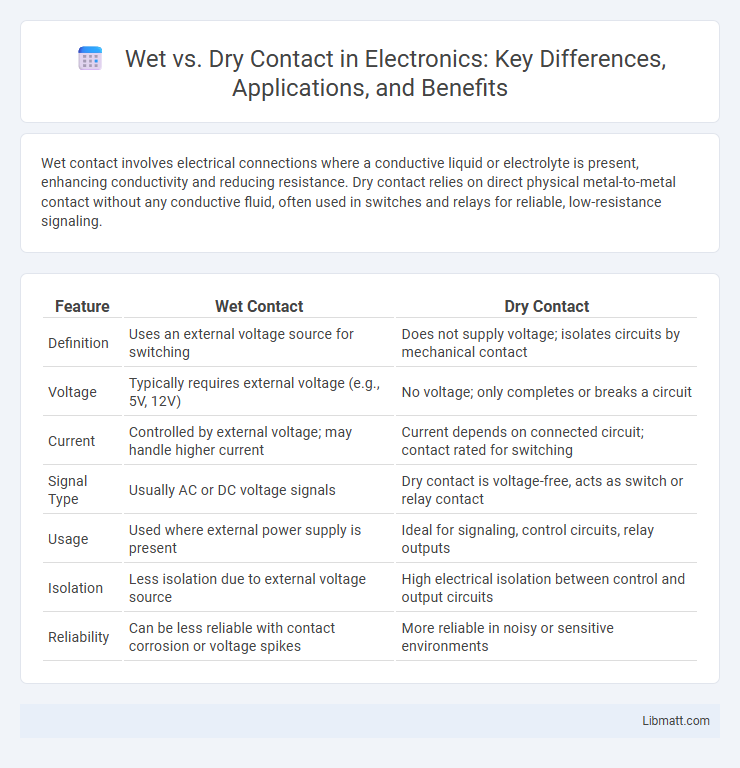

Wet contact involves electrical connections where a conductive liquid or electrolyte is present, enhancing conductivity and reducing resistance. Dry contact relies on direct physical metal-to-metal contact without any conductive fluid, often used in switches and relays for reliable, low-resistance signaling.

Table of Comparison

| Feature | Wet Contact | Dry Contact |

|---|---|---|

| Definition | Uses an external voltage source for switching | Does not supply voltage; isolates circuits by mechanical contact |

| Voltage | Typically requires external voltage (e.g., 5V, 12V) | No voltage; only completes or breaks a circuit |

| Current | Controlled by external voltage; may handle higher current | Current depends on connected circuit; contact rated for switching |

| Signal Type | Usually AC or DC voltage signals | Dry contact is voltage-free, acts as switch or relay contact |

| Usage | Used where external power supply is present | Ideal for signaling, control circuits, relay outputs |

| Isolation | Less isolation due to external voltage source | High electrical isolation between control and output circuits |

| Reliability | Can be less reliable with contact corrosion or voltage spikes | More reliable in noisy or sensitive environments |

Understanding Wet and Dry Contact: A Brief Overview

Wet contact refers to a switch or relay contact that uses a voltage source to ensure consistent electrical continuity, typically involving a low voltage DC supply to detect contact closure reliably. Dry contact, also known as potential-free contact, does not supply voltage or current, instead acting as a simple mechanical switch that isolates control circuits from the switching device's voltage. Understanding the distinction between wet and dry contacts is crucial for selecting appropriate components in control systems, automation, and alarm signaling applications to ensure compatibility and safety.

Key Differences Between Wet and Dry Contact

Wet contact involves the use of a liquid conductor, such as mercury or a conductive fluid, enabling lower resistance and smoother electrical connectivity, often preferred in applications requiring reliable, high-current switching. Dry contact relies on direct metal-to-metal contact without conductive fluid, resulting in higher resistance and potential for contact oxidation, commonly used in signal-level switching where minimal current is involved. The choice between wet and dry contacts depends on factors like current rating, environmental conditions, and maintenance requirements.

How Wet Contact Works in Electrical Systems

Wet contact in electrical systems relies on a conductive liquid, such as an electrolyte solution, to complete the circuit by allowing ions to move between electrodes. This ion movement facilitates electrical conductivity and enables sensors or switches to detect changes in the environment, like humidity or liquid presence. The wet contact method provides responsive, reliable switching especially in applications requiring moisture detection or fluid interaction.

The Mechanism of Dry Contact: What Sets It Apart

Dry contact operates without electrical current flowing through the switching element, relying on mechanical movement to open or close a circuit, which provides isolation from voltage spikes and reduces wear from arcing. This mechanism distinguishes dry contact from wet contact, where the presence of voltage and current flow introduces risks of corrosion and electrical noise. The dry contact's design ensures higher reliability and cleaner signal transmission in sensitive control and monitoring applications.

Common Applications for Wet Contact

Wet contacts are commonly used in industrial automation, control systems, and relay interfaces where electrical isolation and reliable switching of AC or DC loads are essential. These contacts provide stable performance in environments requiring the switching of higher voltages or currents, such as motor starters, contactors, and programmable logic controllers (PLCs). You benefit from enhanced durability and reduced contact wear when managing heavy-duty electrical circuits.

Typical Uses of Dry Contact in Industry

Dry contact sensors are widely used in industrial automation for monitoring and controlling equipment such as conveyors, pumps, and motors due to their reliability and low power consumption. These contacts serve as simple on/off switches that provide isolated signals to control systems, ensuring safety and preventing electrical interference. Common applications include limit switches, safety interlocks, and remote control panel inputs, making them essential in factories, process plants, and building management systems.

Advantages of Using Wet Contact

Wet contact sensors provide more reliable and accurate signal transmission due to their ability to carry external voltage, reducing signal degradation from interference. Their strong electrical isolation minimizes the risk of false triggers and enhances safety in control circuits, especially in industrial automation. Choosing wet contact devices ensures better compatibility with diverse control systems and improves the longevity of your equipment by preventing corrosion-related failures.

Benefits and Drawbacks of Dry Contact

Dry contact switches offer benefits such as isolation from high voltage circuits, reducing the risk of electrical interference and damage to connected devices. They require no external power to operate, enhancing reliability and simplifying system design. However, dry contacts can be less durable in harsh environments and may require more frequent maintenance compared to wet contact options.

Choosing Between Wet and Dry Contact: Factors to Consider

Choosing between wet and dry contact depends on application-specific factors such as the type of electrical load and environmental conditions. Wet contacts offer reliable operation in high-voltage or inductive circuits by using liquid electrolytes to reduce contact resistance and prevent arcing. Dry contacts, preferred in low-voltage or signal-level applications, provide clean switching without the risk of corrosion from moisture but require proper maintenance to avoid oxidation and wear.

Frequently Asked Questions About Wet vs Dry Contact

Wet vs dry contact sensors differ primarily in their output signal type: wet contacts use an external power source, making them suitable for long-distance signal transmission, while dry contacts are passive and rely on the device's internal power. You might ask which is better for industrial automation; wet contacts offer clearer isolation and less noise interference, whereas dry contacts provide simplicity and ease of integration. Understanding these differences helps optimize your control systems for reliability and performance in specific applications.

Wet vs Dry Contact Infographic

libmatt.com

libmatt.com