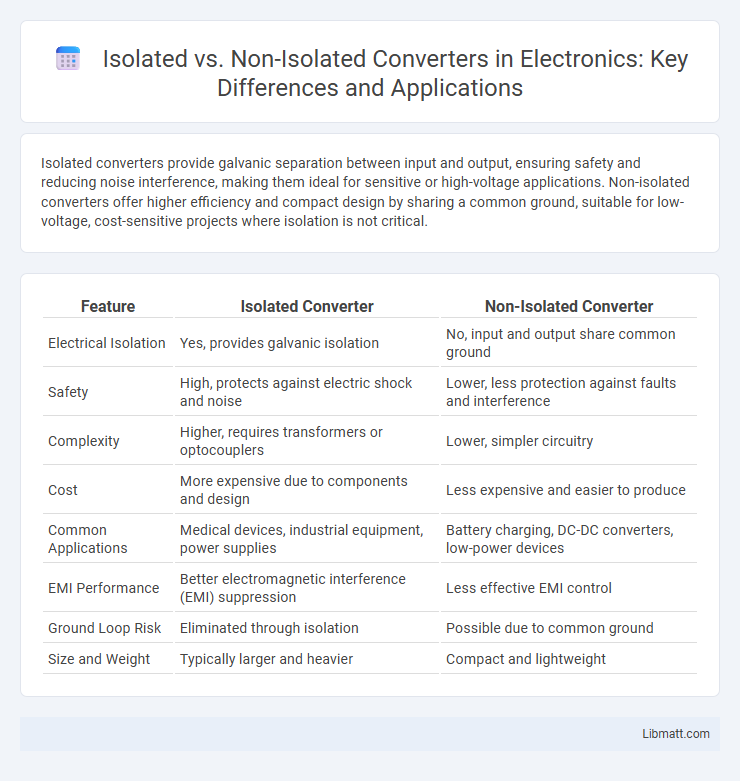

Isolated converters provide galvanic separation between input and output, ensuring safety and reducing noise interference, making them ideal for sensitive or high-voltage applications. Non-isolated converters offer higher efficiency and compact design by sharing a common ground, suitable for low-voltage, cost-sensitive projects where isolation is not critical.

Table of Comparison

| Feature | Isolated Converter | Non-Isolated Converter |

|---|---|---|

| Electrical Isolation | Yes, provides galvanic isolation | No, input and output share common ground |

| Safety | High, protects against electric shock and noise | Lower, less protection against faults and interference |

| Complexity | Higher, requires transformers or optocouplers | Lower, simpler circuitry |

| Cost | More expensive due to components and design | Less expensive and easier to produce |

| Common Applications | Medical devices, industrial equipment, power supplies | Battery charging, DC-DC converters, low-power devices |

| EMI Performance | Better electromagnetic interference (EMI) suppression | Less effective EMI control |

| Ground Loop Risk | Eliminated through isolation | Possible due to common ground |

| Size and Weight | Typically larger and heavier | Compact and lightweight |

Introduction to Power Converters

Power converters are essential devices that transform electrical energy from one form to another, ensuring compatibility between different systems and components. An isolated converter provides electrical separation between input and output through transformers or optocouplers, enhancing safety and noise reduction, while a non-isolated converter directly connects input and output grounds, offering simpler design and higher efficiency. Understanding the differences between isolated and non-isolated converters helps you select the right solution for your power management needs, balancing factors like safety, efficiency, and cost.

Defining Isolated and Non-isolated Converters

Isolated converters utilize electrical isolation between input and output through a transformer, providing enhanced safety and noise reduction in power supply designs. Non-isolated converters lack this galvanic isolation, directly connecting input and output grounds, which results in simpler circuitry and higher efficiency. Understanding the distinction between isolated and non-isolated converters is crucial for selecting the appropriate power conversion approach based on application requirements like safety, size, and electromagnetic interference.

Key Differences Between Isolated and Non-isolated Converters

Isolated converters provide electrical separation between input and output through transformers or optocouplers, enhancing safety and reducing noise interference, while non-isolated converters directly connect input and output circuits, offering higher efficiency and lower cost. Key differences include isolation capability, voltage level handling, and application suitability; isolated converters are essential for medical, industrial, and high-voltage applications, whereas non-isolated converters serve low-voltage, cost-sensitive designs. Isolation also impacts regulatory compliance and electromagnetic interference (EMI) performance, making isolated converters critical for stringent standards.

Operating Principles of Isolated Converters

Isolated converters operate by utilizing transformers or optocouplers to provide galvanic isolation between the input and output, enhancing safety and noise immunity in power conversion processes. These converters transfer energy through magnetic coupling, allowing voltage level shifting and breaking ground loops, which is crucial in medical, industrial, and communication applications. Your system benefits from isolated converters by maintaining signal integrity and protecting sensitive components from high voltage spikes and interference.

Operating Principles of Non-isolated Converters

Non-isolated converters operate by directly connecting the input and output grounds, utilizing components such as inductors, capacitors, and switches to regulate voltage without galvanic isolation. They function based on switching techniques like buck, boost, or buck-boost topologies, efficiently converting power by controlling the duty cycle of the switches. These converters are commonly used in applications where electrical isolation is not critical, offering simpler design and higher efficiency compared to isolated converters.

Efficiency Comparison: Isolated vs Non-isolated

Isolated converters typically exhibit lower efficiency compared to non-isolated converters due to the added losses from isolation components like transformers or optocouplers. Non-isolated converters benefit from simpler topologies and reduced energy dissipation, often achieving efficiencies above 95%. However, isolated converters provide safety and noise immunity advantages, making efficiency trade-offs acceptable in applications requiring electrical isolation.

Safety and Protection Considerations

Isolated converters provide enhanced safety by physically separating input and output circuits, reducing the risk of electric shock and protecting sensitive equipment from voltage spikes. Non-isolated converters lack this isolation barrier, making them more vulnerable to electrical faults and potentially hazardous conditions if system ground faults occur. When selecting your power converter, prioritize isolated designs for applications demanding stringent safety and protection standards.

Typical Applications and Use Cases

Isolated converters are commonly used in medical devices, industrial automation, and telecommunications where galvanic isolation is critical for safety and noise reduction. Non-isolated converters are typically found in battery-powered devices, low-voltage DC-DC power supplies, and consumer electronics where compact size and efficiency are prioritized over isolation. Both converter types play essential roles in power management depending on application-specific requirements for voltage isolation, safety standards, and electromagnetic interference mitigation.

Pros and Cons of Each Converter Type

Isolated converters provide galvanic isolation between input and output, enhancing safety and reducing noise interference, making them ideal for sensitive applications but often at the cost of increased size, complexity, and cost. Non-isolated converters offer higher efficiency and a simpler design with lower cost and smaller footprint, but lack electrical isolation, which can pose risks in systems requiring strict safety standards. Choosing between isolated and non-isolated converters depends on application requirements involving safety, noise immunity, cost, and efficiency priorities.

Selecting the Right Converter for Your Needs

Selecting the right converter hinges on understanding the voltage and safety requirements of your application. Isolated converters provide galvanic isolation, protecting sensitive electronics from ground loops and electrical noise, making them ideal for medical and industrial equipment. Non-isolated converters offer higher efficiency and smaller size, suitable for cost-sensitive or space-constrained projects where isolation is unnecessary.

Isolated vs Non-isolated Converter Infographic

libmatt.com

libmatt.com