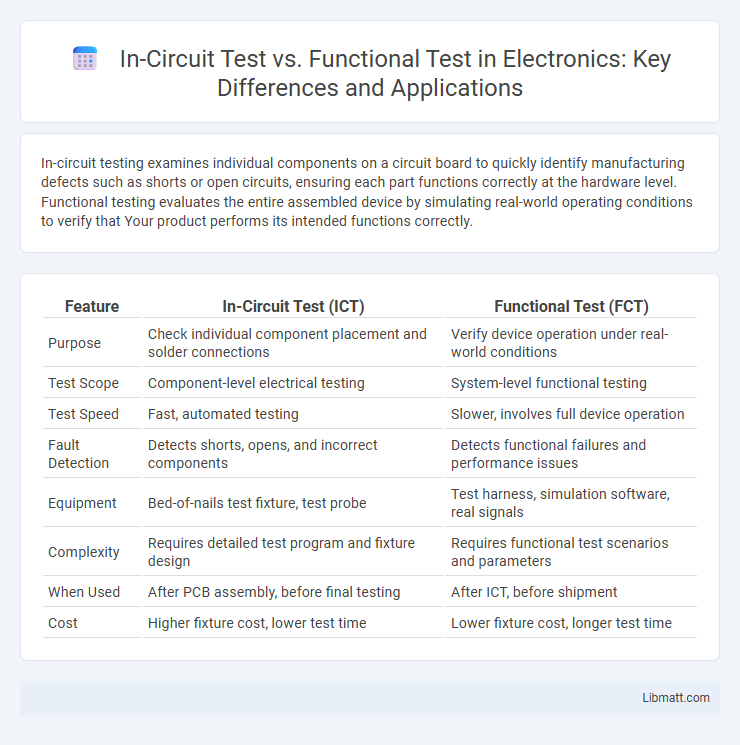

In-circuit testing examines individual components on a circuit board to quickly identify manufacturing defects such as shorts or open circuits, ensuring each part functions correctly at the hardware level. Functional testing evaluates the entire assembled device by simulating real-world operating conditions to verify that Your product performs its intended functions correctly.

Table of Comparison

| Feature | In-Circuit Test (ICT) | Functional Test (FCT) |

|---|---|---|

| Purpose | Check individual component placement and solder connections | Verify device operation under real-world conditions |

| Test Scope | Component-level electrical testing | System-level functional testing |

| Test Speed | Fast, automated testing | Slower, involves full device operation |

| Fault Detection | Detects shorts, opens, and incorrect components | Detects functional failures and performance issues |

| Equipment | Bed-of-nails test fixture, test probe | Test harness, simulation software, real signals |

| Complexity | Requires detailed test program and fixture design | Requires functional test scenarios and parameters |

| When Used | After PCB assembly, before final testing | After ICT, before shipment |

| Cost | Higher fixture cost, lower test time | Lower fixture cost, longer test time |

Introduction to PCB Testing Methods

In-circuit testing (ICT) examines individual components and solder joints on a PCB for defects by applying electrical probes, ensuring accurate assembly and functionality at the component level. Functional testing evaluates the entire PCB under real-world operating conditions, verifying system performance and identifying faults that ICT might miss. These complementary PCB testing methods enhance quality control by detecting manufacturing errors early and confirming overall circuit integrity.

Overview of In-Circuit Testing (ICT)

In-Circuit Testing (ICT) is a method used to evaluate individual components and solder connections on a populated printed circuit board (PCB) by applying electrical probes directly to test points. This process allows for the detection of manufacturing defects such as short circuits, open circuits, and incorrect component values with high accuracy and speed. ICT ensures your PCB assemblies meet quality standards before progressing to more comprehensive functional or system-level tests.

Overview of Functional Testing (FCT)

Functional Testing (FCT) evaluates the complete operation of a finished electronic device by simulating real-world usage conditions to verify its performance against specified requirements. This test method focuses on validating system-level functionality, ensuring all integrated components work together correctly without delving into individual component faults. Your product's quality assurance benefits from FCT by detecting issues that may not appear in isolated in-circuit tests, thereby improving overall reliability and customer satisfaction.

Key Differences Between ICT and FCT

In-circuit Test (ICT) primarily inspects individual components and solder joints on a PCB, using bed-of-nails fixtures to check for manufacturing defects such as shorts, opens, and incorrect component values. Functional Test (FCT) evaluates the fully assembled device's performance by simulating real-world operating conditions to verify that Your product functions according to its design specifications. The key differences between ICT and FCT lie in their scope: ICT focuses on physical and structural integrity at the component level, while FCT ensures the overall system functionality and user-interaction experience.

Advantages of In-Circuit Testing

In-circuit testing offers precise fault detection by examining each component individually on the PCB, ensuring early identification of manufacturing defects such as soldering issues and component failures. This testing method significantly reduces debugging time and repair costs by isolating faults at the component level. Your production process benefits from increased efficiency and higher yield rates due to the thorough and automated nature of in-circuit testing.

Advantages of Functional Testing

Functional testing offers the advantage of verifying the complete operation of a device or system under realistic conditions, ensuring that all components work together as intended. It detects issues related to integration, software, and overall performance that in-circuit tests may miss. Functional tests are essential for validating user requirements and enhancing product reliability before deployment.

Limitations of In-Circuit Testing

In-circuit testing (ICT) faces limitations in detecting faults related to analog components, complex integrated circuits, and solder joint defects, which are often better identified through functional testing. ICT primarily assesses individual components and connections on a PCB but may miss issues arising during system operation or under real-world conditions. Your testing strategy should integrate both methods to ensure comprehensive coverage and maximize fault detection efficiency.

Limitations of Functional Testing

Functional testing cannot detect certain types of faults such as open circuits, shorts, or component-level defects that do not affect the overall functionality but degrade reliability. It relies on the device under test operating correctly at the system level, which may miss subtle internal hardware issues. Limited access to internal nodes prevents comprehensive fault coverage compared to in-circuit testing methods.

Choosing the Right Test Method for Your Application

Selecting the appropriate test method depends on the complexity and stage of the PCB assembly process. In-circuit test (ICT) excels in identifying manufacturing defects by probing individual components and verifying solder joints, making it ideal for early production and troubleshooting. Functional test (FCT) evaluates the complete system performance under real operating conditions, ensuring end-use reliability and confirming that the product meets design specifications.

Conclusion: ICT vs Functional Testing Decision Guide

Choosing between In-Circuit Test (ICT) and Functional Testing depends on the specific needs of the manufacturing process and product complexity. ICT excels in detecting board-level faults like shorts, opens, and component issues early in production, ensuring higher yield and reduced rework costs. Functional Testing verifies the complete functionality of the assembled product, making it essential for validating system-level performance and final quality assurance.

In-circuit vs Functional Test Infographic

libmatt.com

libmatt.com