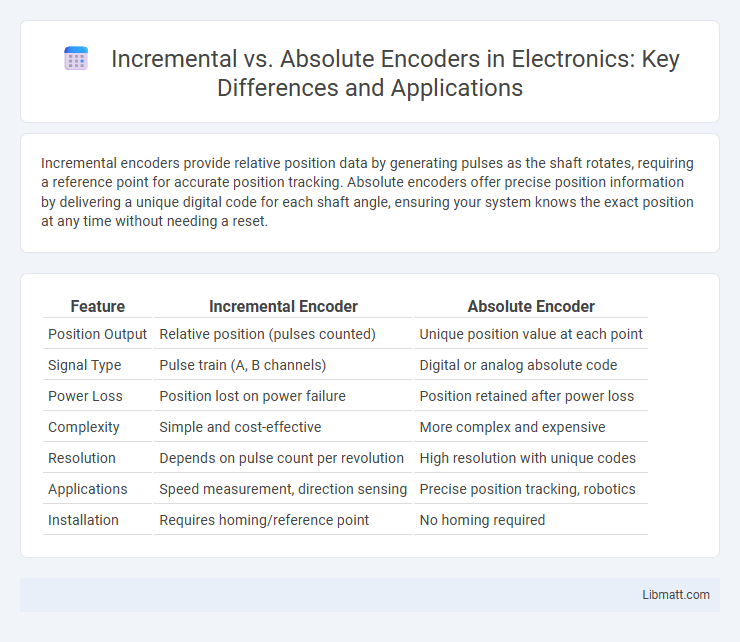

Incremental encoders provide relative position data by generating pulses as the shaft rotates, requiring a reference point for accurate position tracking. Absolute encoders offer precise position information by delivering a unique digital code for each shaft angle, ensuring your system knows the exact position at any time without needing a reset.

Table of Comparison

| Feature | Incremental Encoder | Absolute Encoder |

|---|---|---|

| Position Output | Relative position (pulses counted) | Unique position value at each point |

| Signal Type | Pulse train (A, B channels) | Digital or analog absolute code |

| Power Loss | Position lost on power failure | Position retained after power loss |

| Complexity | Simple and cost-effective | More complex and expensive |

| Resolution | Depends on pulse count per revolution | High resolution with unique codes |

| Applications | Speed measurement, direction sensing | Precise position tracking, robotics |

| Installation | Requires homing/reference point | No homing required |

Introduction to Encoders

Encoders convert mechanical motion into electrical signals to provide precise position or speed feedback in automation and robotics. Incremental encoders generate relative position signals by counting pulses from a reference point, ideal for applications requiring speed measurement and position tracking over short distances. Absolute encoders output unique position codes for each shaft position, enabling direct position identification without the need for homing, enhancing accuracy and reliability in complex systems.

What is an Incremental Encoder?

An incremental encoder is a rotary or linear motion sensor that produces a series of pulses proportional to the movement of a shaft or object, enabling precise measurement of position changes and speed. It generates output signals, typically quadrature pulses, that must be processed by external electronics to determine direction and distance traveled. Commonly used in robotics, CNC machines, and industrial automation, incremental encoders rely on relative position tracking rather than providing an absolute position reference.

What is an Absolute Encoder?

An Absolute Encoder provides a unique position value or digital code for each shaft position, enabling precise and consistent tracking even after power loss. Unlike incremental encoders, it does not require a reference point or counting pulses to determine the exact position. When selecting your motion control system, Absolute Encoders ensure reliable, real-time position feedback in industrial applications where accuracy and continuity are crucial.

Key Differences Between Incremental and Absolute Encoders

Incremental encoders provide relative position data by generating pulses corresponding to movement, while absolute encoders deliver unique position values for each shaft position, ensuring precise location tracking. Incremental encoders require an external reference point after power loss to determine position, whereas absolute encoders retain position information without the need for homing. The key differences lie in data output format, position accuracy maintenance during power interruptions, and integration complexity, making absolute encoders ideal for applications demanding exact position identification.

Working Principles of Incremental Encoders

Incremental encoders operate by generating a series of pulses as the shaft rotates, where each pulse corresponds to a fixed increment of movement, enabling precise measurement of position changes. The output signals typically consist of two square waves (A and B channels) in quadrature, allowing the determination of rotation direction and speed. Your control system interprets these pulses to track relative position but requires a reference point for absolute positioning.

Working Principles of Absolute Encoders

Absolute encoders operate by assigning a unique digital code to each shaft position using a coded disk and optical or magnetic sensors, allowing precise position tracking even after power loss. Unlike incremental encoders, which track relative movement, absolute encoders provide a direct reading of the exact angular position by continuously outputting a distinct signal correlated to the shaft's angle. Your control system benefits from this reliability in applications requiring accurate positioning without the need for homing or position referencing on startup.

Advantages of Incremental Encoders

Incremental encoders offer precise position feedback with a simpler and more cost-effective design compared to absolute encoders, making them ideal for applications requiring real-time speed and direction monitoring. Their ability to provide high-resolution output pulses allows for accurate measurement of shaft rotation and velocity without the need for complex data integration. You benefit from easier installation and maintenance, as incremental encoders typically have fewer wiring requirements and deliver fast response times.

Benefits of Absolute Encoders

Absolute encoders provide precise position feedback by delivering a unique digital code for each shaft position, eliminating the need for homing procedures after power loss. Their ability to maintain accurate position data during power outages enhances system reliability and reduces downtime in automation and robotics. High-resolution output and immunity to signal loss make absolute encoders essential for applications demanding precise and continuous position monitoring.

Common Applications for Each Encoder Type

Incremental encoders are widely used in industrial automation for speed monitoring and position tracking in conveyor systems, robotics, and CNC machinery due to their ability to provide real-time relative movement data. Absolute encoders find common application in robotics, manufacturing equipment, and aerospace where precise positional feedback is critical for safety and accuracy, as they provide a unique position value for each shaft angle. Your choice between these encoders depends on whether you need continuous relative motion tracking or exact positional information after power loss.

Choosing the Right Encoder for Your Application

Choosing the right encoder for your application depends on accuracy, speed, and environmental conditions. Incremental encoders offer precise position changes and high resolution ideal for speed measurement and feedback control, while absolute encoders provide unique position values for exact location tracking without losing data during power loss. Evaluate factors like required accuracy, system complexity, and cost to determine which encoder best suits your operational needs.

Incremental vs Absolute encoder Infographic

libmatt.com

libmatt.com