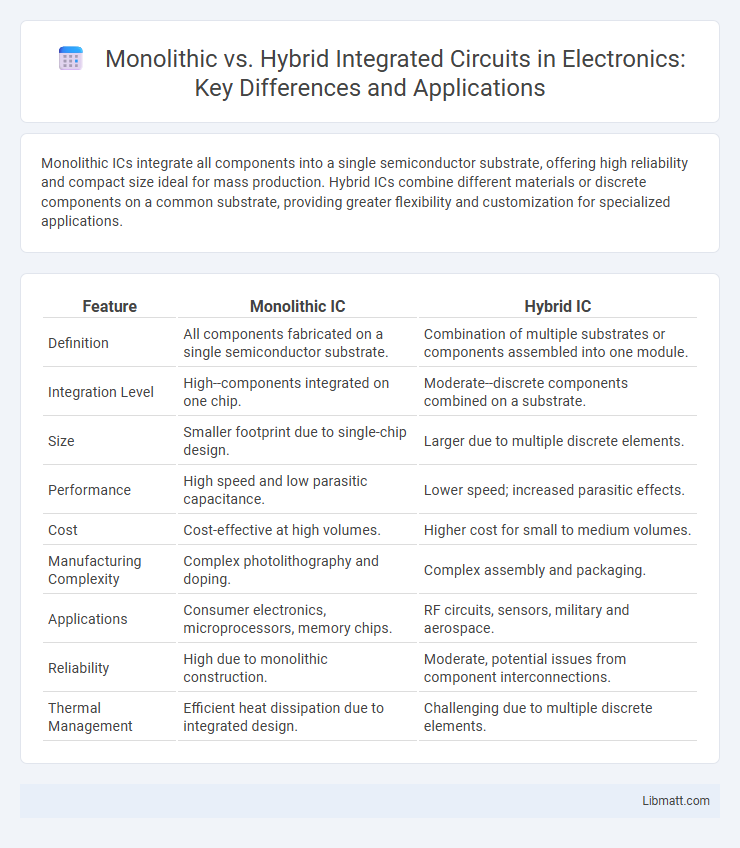

Monolithic ICs integrate all components into a single semiconductor substrate, offering high reliability and compact size ideal for mass production. Hybrid ICs combine different materials or discrete components on a common substrate, providing greater flexibility and customization for specialized applications.

Table of Comparison

| Feature | Monolithic IC | Hybrid IC |

|---|---|---|

| Definition | All components fabricated on a single semiconductor substrate. | Combination of multiple substrates or components assembled into one module. |

| Integration Level | High--components integrated on one chip. | Moderate--discrete components combined on a substrate. |

| Size | Smaller footprint due to single-chip design. | Larger due to multiple discrete elements. |

| Performance | High speed and low parasitic capacitance. | Lower speed; increased parasitic effects. |

| Cost | Cost-effective at high volumes. | Higher cost for small to medium volumes. |

| Manufacturing Complexity | Complex photolithography and doping. | Complex assembly and packaging. |

| Applications | Consumer electronics, microprocessors, memory chips. | RF circuits, sensors, military and aerospace. |

| Reliability | High due to monolithic construction. | Moderate, potential issues from component interconnections. |

| Thermal Management | Efficient heat dissipation due to integrated design. | Challenging due to multiple discrete elements. |

Introduction to Integrated Circuits

Integrated circuits (ICs) are semiconductor devices that integrate multiple electronic components into a single chip, enabling compact and efficient electronic systems. Monolithic ICs contain all components fabricated on a single semiconductor substrate, offering high reliability and performance consistency. Hybrid ICs combine different components or substrates, such as silicon chips and passive elements, providing flexibility in material selection and component integration for specialized applications.

Defining Monolithic ICs

Monolithic ICs integrate all electronic components, such as transistors, resistors, and capacitors, onto a single semiconductor substrate, typically silicon. This compact design enhances performance, reduces parasitic elements, and lowers manufacturing costs compared to hybrid ICs, which combine multiple discrete components on a substrate. Understanding monolithic ICs allows you to select the most efficient solution for applications requiring high reliability and miniaturization.

Exploring Hybrid ICs

Hybrid ICs integrate multiple semiconductor technologies such as silicon-based chips and passive components onto a single substrate, offering enhanced performance and flexibility not achievable with monolithic ICs alone. These circuits excel in applications requiring customized solutions, combining the benefits of different materials and manufacturing processes to optimize functionality and reliability. Their ability to accommodate diverse components makes hybrid ICs ideal for high-frequency, power management, and aerospace systems where precision and durability are critical.

Key Differences Between Monolithic and Hybrid ICs

Monolithic ICs are fabricated entirely on a single semiconductor substrate, resulting in compact size, low parasitic capacitance, and high reliability, whereas Hybrid ICs combine multiple discrete components or chips mounted on a ceramic or insulating base, allowing flexibility in material choice and customization. Monolithic ICs excel in mass production with superior performance consistency, while Hybrid ICs offer advantages in high-power applications and integration of diverse technologies. Cost efficiency favors monolithic ICs in large-scale production, whereas hybrid ICs are preferable for specialized, low-volume, or high-frequency circuits requiring tailored solutions.

Manufacturing Processes Involved

Monolithic ICs are manufactured using photolithography and semiconductor etching to integrate all components on a single silicon wafer, ensuring uniformity and miniaturization. Hybrid ICs combine multiple discrete components like silicon chips, resistors, and capacitors assembled on a ceramic substrate through processes such as die bonding and wire bonding. Understanding these manufacturing processes helps you choose the right IC type based on complexity, cost, and performance requirements.

Performance and Reliability Comparison

Monolithic ICs generally offer superior performance due to shorter interconnects and reduced parasitic capacitance, resulting in faster signal processing and lower power consumption. Hybrid ICs provide greater reliability in harsh environments by using discrete components on a ceramic substrate, enhancing thermal management and mechanical stability. The choice between monolithic and hybrid ICs depends on the specific application requirements for speed, power efficiency, and environmental tolerance.

Cost Implications and Scalability

Monolithic ICs offer lower production costs through integration on a single semiconductor substrate, reducing packaging and assembly expenses, while Hybrid ICs incur higher initial costs due to complex assembly of discrete components but provide cost advantages in small volume or specialized applications. Scalability of Monolithic ICs is superior, benefiting from established semiconductor manufacturing processes that enable mass production and miniaturization. Hybrid ICs face scalability challenges as manual assembly and diverse materials limit automation and large-scale manufacturing efficiency.

Applications of Monolithic ICs

Monolithic ICs find extensive applications in consumer electronics, such as smartphones, digital cameras, and portable media players, due to their compact size and cost-efficiency. They are also critical in automotive systems for engine control units and safety features, providing reliable performance under harsh conditions. Your choice of monolithic ICs can enhance integration and reduce power consumption in medical devices like pacemakers and diagnostic equipment.

Applications of Hybrid ICs

Hybrid ICs are widely used in aerospace, telecommunications, and medical devices due to their ability to combine diverse materials and components in a single package, enhancing performance and reliability. They provide customized solutions for high-frequency circuits, power management, and sensor integration, where traditional monolithic ICs may fall short. Your projects requiring complex, high-precision functions benefit significantly from the adaptability and robustness of hybrid IC technology.

Choosing Between Monolithic and Hybrid ICs

Choosing between monolithic and hybrid ICs depends largely on application requirements such as integration density, cost, and performance. Monolithic ICs offer higher integration and performance for mass production, while hybrid ICs provide flexibility and customization for specialized applications. Evaluating factors like thermal management, frequency response, and production volume ensures optimal selection for semiconductor solutions.

Monolithic vs Hybrid IC Infographic

libmatt.com

libmatt.com