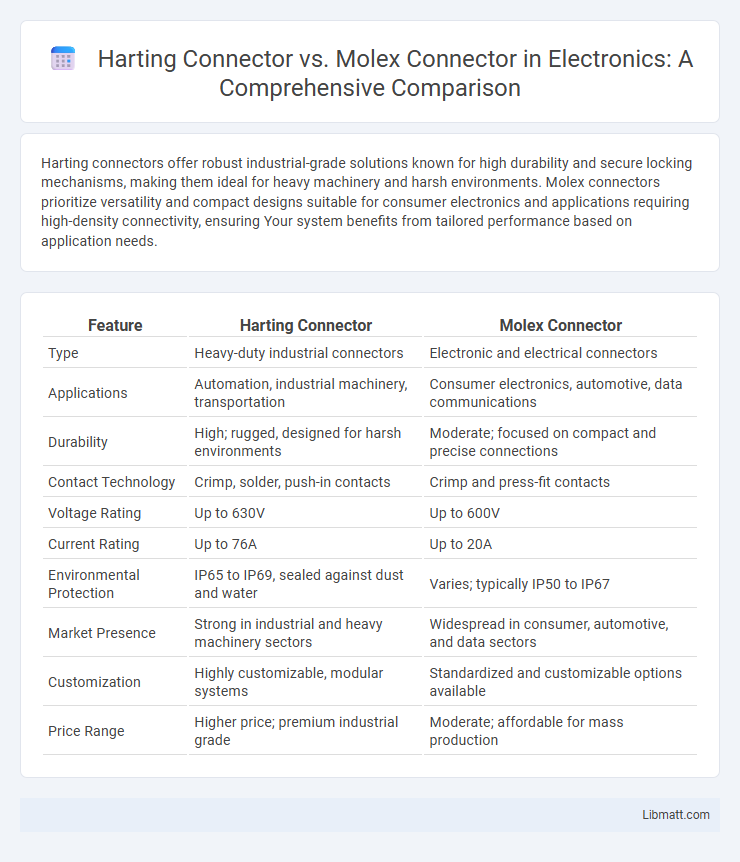

Harting connectors offer robust industrial-grade solutions known for high durability and secure locking mechanisms, making them ideal for heavy machinery and harsh environments. Molex connectors prioritize versatility and compact designs suitable for consumer electronics and applications requiring high-density connectivity, ensuring Your system benefits from tailored performance based on application needs.

Table of Comparison

| Feature | Harting Connector | Molex Connector |

|---|---|---|

| Type | Heavy-duty industrial connectors | Electronic and electrical connectors |

| Applications | Automation, industrial machinery, transportation | Consumer electronics, automotive, data communications |

| Durability | High; rugged, designed for harsh environments | Moderate; focused on compact and precise connections |

| Contact Technology | Crimp, solder, push-in contacts | Crimp and press-fit contacts |

| Voltage Rating | Up to 630V | Up to 600V |

| Current Rating | Up to 76A | Up to 20A |

| Environmental Protection | IP65 to IP69, sealed against dust and water | Varies; typically IP50 to IP67 |

| Market Presence | Strong in industrial and heavy machinery sectors | Widespread in consumer, automotive, and data sectors |

| Customization | Highly customizable, modular systems | Standardized and customizable options available |

| Price Range | Higher price; premium industrial grade | Moderate; affordable for mass production |

Introduction to Harting and Molex Connectors

Harting connectors are renowned for their robust industrial-grade solutions, specializing in heavy-duty, high-reliability electrical connections used in automation, machinery, and transportation sectors. Molex connectors offer a broad range of versatile electronic interconnects, including wire-to-board, board-to-board, and power connectors, catering extensively to consumer electronics, data communications, and automotive applications. Both Harting and Molex emphasize quality and innovation, but Harting prioritizes ruggedness for harsh environments, while Molex focuses on compact, high-density designs for diverse electronic systems.

Key Features of Harting Connectors

Harting connectors are renowned for their robust industrial-grade design, ensuring reliable performance in harsh environments with high vibration and temperature resistance. They feature modular construction options, allowing customization for signal, power, and data transmission within a single housing. You benefit from easy installation and maintenance due to their push-pull locking mechanism and modular contact inserts, making Harting connectors ideal for industrial automation and heavy machinery applications.

Key Features of Molex Connectors

Molex connectors are renowned for their versatile design, supporting a broad range of applications from consumer electronics to industrial machinery with high reliability. They feature a variety of pin configurations, robust housing materials, and secure locking mechanisms that ensure stable electrical connections in demanding environments. Molex connectors also offer excellent resistance to vibration, temperature extremes, and moisture, making them ideal for harsh operating conditions.

Design Differences: Harting vs Molex

Harting connectors feature a robust, industrial design optimized for high durability and secure connections in harsh environments, utilizing a modular, heavy-duty approach with a spring-loaded mechanism. Molex connectors prioritize compactness and versatility, offering a wide range of sizes and pin configurations tailored for electronics and consumer devices, with a focus on ease of assembly and reliable signal integrity. Your choice between Harting and Molex depends on the application's environmental demands and the required connector form factor.

Performance and Reliability Comparison

Harting connectors offer exceptional durability with rugged metal housings and high-contact integrity, maintaining performance in harsh industrial environments. Molex connectors provide reliable electrical connections with a focus on versatility and ease of installation, ideal for diverse applications but sometimes less resistant to extreme conditions. Your choice depends on whether you prioritize Harting's robustness for demanding settings or Molex's adaptability for varied use cases.

Application Suitability and Industry Use Cases

Harting connectors excel in heavy industrial environments such as manufacturing automation, machinery, and transportation due to their robust design and high durability. Molex connectors are preferred in consumer electronics, telecommunications, and computer hardware where compact size and high pin density are critical. Understanding your specific application requirements helps ensure you select the right connector for optimal performance and reliability.

Electrical and Mechanical Specifications

Harting connectors offer robust electrical performance with high current ratings up to 40A and voltages reaching 630V, supported by precision-crafted contacts for reliable signal transmission. Molex connectors provide versatile electrical specifications, featuring a wide range of current capacities from 1A to over 20A and voltage ratings typically up to 250V, tailored for compact electronic applications. Your choice between Harting and Molex should consider mechanical durability, as Harting connectors emphasize rugged industrial-grade housings with high resistance to vibration and shock, while Molex focuses on lightweight designs with varied locking mechanisms suited for consumer electronics.

Installation and Maintenance Considerations

Harting connectors feature robust industrial-grade designs that allow for straightforward installation with minimal tooling, reducing downtime in maintenance. Molex connectors offer versatile, easy-to-use interfaces suitable for quick assembly but may require more frequent checks due to their compact, less heavy-duty construction. Your choice depends on whether you prioritize durability and lower maintenance or ease of initial installation.

Cost Analysis: Harting vs Molex Connectors

Harting connectors generally present a higher upfront cost compared to Molex connectors due to their robust industrial-grade design and specialized applications. Molex connectors offer a broader range of affordable options suitable for consumer electronics and less demanding environments, resulting in lower initial investment. Total cost of ownership for Harting connectors can be justified by their durability and lower maintenance needs, whereas Molex connectors may incur higher replacement and repair expenses over time.

Choosing the Right Connector for Your Project

Harting connectors offer rugged durability and high-performance metal housings ideal for industrial automation, while Molex connectors provide versatile, cost-effective solutions suited for consumer electronics and smaller-scale applications. Selecting the right connector depends on project requirements such as environmental conditions, current and voltage ratings, and mechanical stress tolerance. For heavy-duty, high-reliability connections, Harting excels, whereas Molex connectors are preferred for compact designs and flexibility in signal and power distribution.

Harting Connector vs Molex Connector Infographic

libmatt.com

libmatt.com