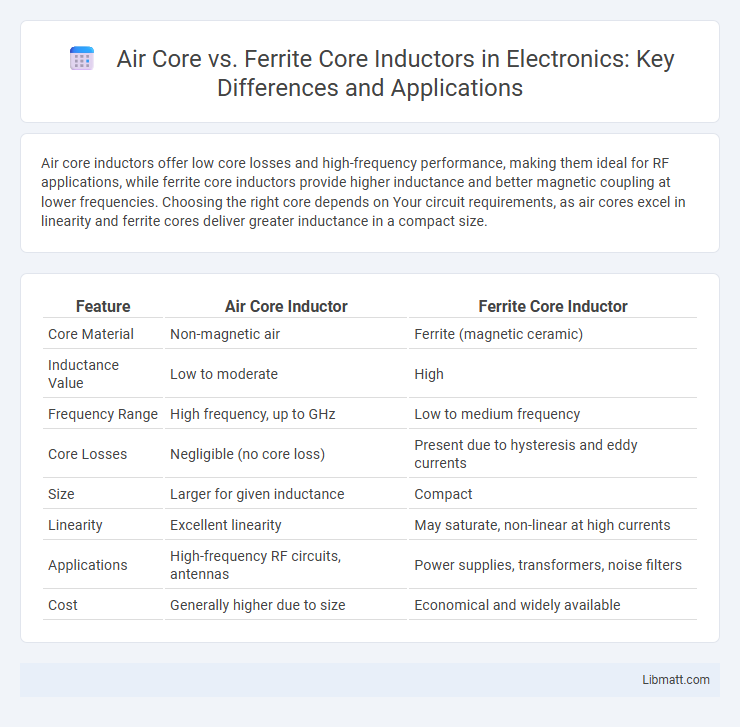

Air core inductors offer low core losses and high-frequency performance, making them ideal for RF applications, while ferrite core inductors provide higher inductance and better magnetic coupling at lower frequencies. Choosing the right core depends on Your circuit requirements, as air cores excel in linearity and ferrite cores deliver greater inductance in a compact size.

Table of Comparison

| Feature | Air Core Inductor | Ferrite Core Inductor |

|---|---|---|

| Core Material | Non-magnetic air | Ferrite (magnetic ceramic) |

| Inductance Value | Low to moderate | High |

| Frequency Range | High frequency, up to GHz | Low to medium frequency |

| Core Losses | Negligible (no core loss) | Present due to hysteresis and eddy currents |

| Size | Larger for given inductance | Compact |

| Linearity | Excellent linearity | May saturate, non-linear at high currents |

| Applications | High-frequency RF circuits, antennas | Power supplies, transformers, noise filters |

| Cost | Generally higher due to size | Economical and widely available |

Introduction to Inductors

Inductors store energy in a magnetic field when electrical current flows through them, with their core material significantly influencing performance. Air core inductors feature a non-magnetic core, providing low inductance and excellent high-frequency response, making them ideal for RF applications. Ferrite core inductors utilize a ferrite material core, enhancing inductance and energy storage capacity while reducing core losses in power supply circuits.

Overview of Air Core Inductors

Air core inductors feature a coil wound around a non-magnetic material, eliminating core losses and providing high-frequency performance. These inductors offer low inductance values and maintain linearity, making them ideal for RF circuits and applications requiring minimal signal distortion. Your design benefits from stable inductance and reduced energy loss when choosing air core inductors in high-frequency environments.

Overview of Ferrite Core Inductors

Ferrite core inductors utilize a magnetic ferrite material that offers high permeability, enabling efficient energy storage and reduced core losses in high-frequency applications. These inductors excel in minimizing electromagnetic interference (EMI) and maintaining stable inductance under varying current loads. Your electronic circuits benefit from ferrite core inductors when compact size and enhanced performance at RF and switching frequencies are crucial.

Key Differences: Air Core vs Ferrite Core

Air core inductors use a non-magnetic material as their core, offering low inductance values, high-frequency performance, and minimal core losses, making them ideal for RF applications. Ferrite core inductors feature a magnetic ferrite material that provides higher inductance, improved magnetic flux confinement, and greater energy storage capacity, suitable for power electronics and low-frequency circuits. The key differences lie in core material, frequency response, inductance range, and associated core losses affecting efficiency and application suitability.

Electrical Performance Comparison

Air core inductors offer superior electrical performance with low core losses and high linearity, making them ideal for high-frequency applications and signal integrity. Ferrite core inductors provide higher inductance values and better magnetic coupling due to their high permeability but may suffer from core losses and saturation at higher currents. Your choice depends on the required frequency range, inductance, and efficiency needed for optimal circuit performance.

Applications of Air Core Inductors

Air core inductors are commonly used in high-frequency applications such as radio transmitters, receivers, and RF circuits due to their low inductance values and minimal energy loss. Their non-magnetic cores eliminate core saturation and hysteresis, making them ideal for resonant circuits and signal processing in communication devices. These inductors are also favored in precision tuning circuits and filter networks where stable inductance and low distortion are critical.

Applications of Ferrite Core Inductors

Ferrite core inductors are widely used in high-frequency applications such as switching power supplies, RF circuits, and electromagnetic interference (EMI) filters due to their high magnetic permeability and low core losses. These inductors provide efficient energy storage and noise suppression in power electronics and communication devices. Their compact size and excellent performance at high frequencies make ferrite core inductors ideal for modern electronic equipment and signal processing.

Advantages and Disadvantages of Each Type

Air core inductors offer high linearity and low core losses, making them ideal for high-frequency applications, but they usually have lower inductance values and larger physical sizes. Ferrite core inductors provide higher inductance and compact size due to their magnetic core material, which enhances energy storage, though they suffer from core losses and saturation at high currents. Choosing between air core and ferrite core inductors depends on the required frequency range, inductance, size constraints, and efficiency needs.

Choosing the Right Inductor Core Material

Choosing the right inductor core material depends on the application's frequency, power requirements, and efficiency goals. Air core inductors offer low core losses and high linearity, making them ideal for high-frequency and radio-frequency circuits, while ferrite core inductors provide higher inductance and energy storage capabilities suited for power electronics and low-frequency applications. Understanding the trade-offs in magnetic permeability, core losses, and saturation current is essential for optimizing circuit performance and reliability.

Conclusion: Air Core or Ferrite Core?

Air core inductors offer superior high-frequency performance due to negligible core losses and stable inductance, making them ideal for RF and high-speed applications. Ferrite core inductors provide higher inductance values and better magnetic flux containment, which suits power electronics where size and efficiency matter most. Your choice depends on application requirements: prioritize air cores for high-frequency stability and ferrite cores for compact, high-inductance solutions.

Air Core vs Ferrite Core Inductor Infographic

libmatt.com

libmatt.com