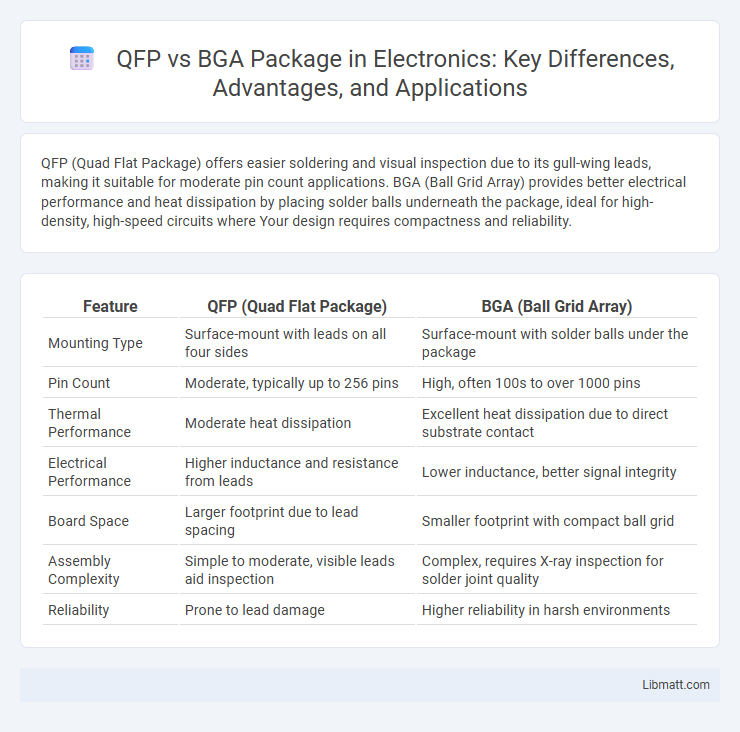

QFP (Quad Flat Package) offers easier soldering and visual inspection due to its gull-wing leads, making it suitable for moderate pin count applications. BGA (Ball Grid Array) provides better electrical performance and heat dissipation by placing solder balls underneath the package, ideal for high-density, high-speed circuits where Your design requires compactness and reliability.

Table of Comparison

| Feature | QFP (Quad Flat Package) | BGA (Ball Grid Array) |

|---|---|---|

| Mounting Type | Surface-mount with leads on all four sides | Surface-mount with solder balls under the package |

| Pin Count | Moderate, typically up to 256 pins | High, often 100s to over 1000 pins |

| Thermal Performance | Moderate heat dissipation | Excellent heat dissipation due to direct substrate contact |

| Electrical Performance | Higher inductance and resistance from leads | Lower inductance, better signal integrity |

| Board Space | Larger footprint due to lead spacing | Smaller footprint with compact ball grid |

| Assembly Complexity | Simple to moderate, visible leads aid inspection | Complex, requires X-ray inspection for solder joint quality |

| Reliability | Prone to lead damage | Higher reliability in harsh environments |

Introduction to QFP and BGA Packages

Quad Flat Package (QFP) and Ball Grid Array (BGA) are popular surface-mount packaging technologies used for integrated circuits in electronics manufacturing. QFP features leads extending from all four sides of the package, providing easy visual inspection and soldering but limited pin density, while BGA employs an array of solder balls underneath the package, offering higher pin counts, improved thermal and electrical performance, and reduced inductance. The choice between QFP and BGA depends on factors such as board space constraints, heat dissipation requirements, and complexity of the electronic design.

Overview of QFP (Quad Flat Package)

The Quad Flat Package (QFP) is a surface-mount integrated circuit package characterized by its flat rectangular shape and leads extending from all four sides, enabling efficient electrical connections on printed circuit boards (PCBs). QFPs are widely used for medium to high-pin-count applications in consumer electronics, automotive systems, and industrial devices due to their balanced thermal performance and ease of inspection. This package type supports a range of fine-pitch leads, typically from 0.4 mm to 1.0 mm, providing versatility for various component densities without the complexity of ball grid arrays.

Overview of BGA (Ball Grid Array)

BGA (Ball Grid Array) is a semiconductor package that offers higher pin density compared to QFP (Quad Flat Package) by using an array of solder balls on the underside for electrical connections, improving thermal and electrical performance. This design minimizes lead inductance and enables better heat dissipation, making BGA ideal for high-speed and high-density applications. When selecting a package, your choice of BGA can enhance circuit reliability and reduce package size, especially in compact electronic devices.

Key Differences Between QFP and BGA

QFP (Quad Flat Package) features gull-wing leads extending from all four sides, making it suitable for easy visual inspection and manual soldering, while BGA (Ball Grid Array) uses solder balls underneath the package for higher pin density and improved heat dissipation. BGA provides superior electrical performance due to shorter interconnection paths and reduced inductance, whereas QFP designs are often limited by longer lead lengths and susceptibility to mechanical stress. PCB design complexity differs as BGA requires precise soldering equipment and X-ray inspection, contrasting with QFP's compatibility with traditional surface-mount assembly processes.

Mechanical and Thermal Performance

QFP (Quad Flat Package) offers moderate thermal performance with exposed leads allowing better heat dissipation, while BGA (Ball Grid Array) exhibits superior thermal conductivity due to solder balls providing direct contact to the PCB, enhancing heat transfer. Mechanically, QFP packages are more susceptible to lead damage and stress during assembly, whereas BGA packages deliver improved mechanical reliability and reduced warpage thanks to their compact solder ball arrays. Understanding these differences helps you select the optimal package for applications requiring robust thermal management and mechanical stability.

Assembly and Soldering Processes

QFP (Quad Flat Package) and BGA (Ball Grid Array) differ significantly in assembly and soldering processes. QFP packages require precise alignment of leads with PCB pads and are soldered using wave or reflow soldering, which can be more prone to solder bridging due to fine lead pitches. BGA packages use an array of solder balls under the component, improving thermal performance and electrical connections, but require X-ray inspection for solder joint quality verification due to hidden joints during the reflow soldering process.

Reliability and Durability Comparison

QFP (Quad Flat Package) and BGA (Ball Grid Array) differ significantly in reliability and durability, with BGA offering superior thermal performance and mechanical stability due to its solder ball connections that provide better stress distribution. QFPs are more prone to solder joint fatigue and damage from thermal cycling because their leads extend outward and are susceptible to bending and cracking. Consequently, BGA packages are preferred in high-reliability applications requiring enhanced durability and resistance to vibration and thermal shock.

Cost Considerations: QFP vs. BGA

QFP (Quad Flat Package) typically offers lower initial costs due to simpler manufacturing and easier inspection processes compared to BGA (Ball Grid Array). BGA, while generally more expensive upfront, provides better performance and reliability in high-density applications, potentially reducing long-term costs associated with failure or rework. Your choice between QFP and BGA should balance immediate budget constraints against the benefits of improved thermal management and signal integrity inherent in BGA packages.

Applications and Usage Scenarios

QFP (Quad Flat Package) is widely used in consumer electronics, automotive systems, and industrial applications where easy inspection and rework are essential due to its leaded design. BGA (Ball Grid Array) packages dominate high-performance computing, telecommunications, and advanced mobile devices because of their superior thermal management, higher pin density, and enhanced electrical performance. Both packages cater to different usage scenarios; QFP suits medium pin count applications requiring cost-effective assembly, while BGA is preferred for compact, high-density circuits demanding robust mechanical and thermal reliability.

Choosing the Right Package for Your Project

Choosing the right package for your project depends on factors like board space, thermal performance, and pin count requirements. QFP (Quad Flat Package) offers easy inspection and soldering with exposed leads ideal for moderate pin counts and prototyping. BGA (Ball Grid Array) provides superior thermal dissipation and electrical performance, making it suitable for high-density applications where compact size and reliability are critical.

QFP vs BGA Package Infographic

libmatt.com

libmatt.com