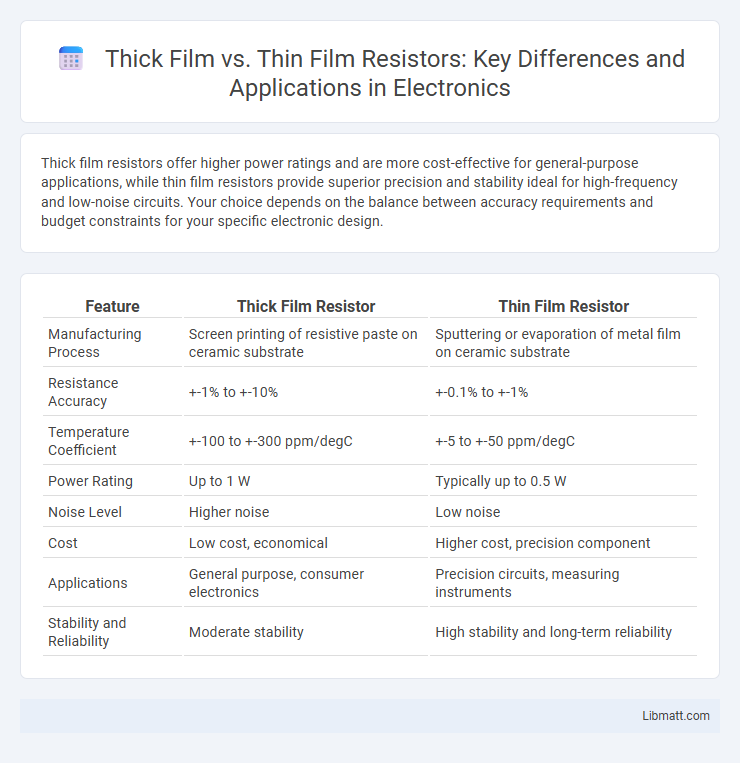

Thick film resistors offer higher power ratings and are more cost-effective for general-purpose applications, while thin film resistors provide superior precision and stability ideal for high-frequency and low-noise circuits. Your choice depends on the balance between accuracy requirements and budget constraints for your specific electronic design.

Table of Comparison

| Feature | Thick Film Resistor | Thin Film Resistor |

|---|---|---|

| Manufacturing Process | Screen printing of resistive paste on ceramic substrate | Sputtering or evaporation of metal film on ceramic substrate |

| Resistance Accuracy | +-1% to +-10% | +-0.1% to +-1% |

| Temperature Coefficient | +-100 to +-300 ppm/degC | +-5 to +-50 ppm/degC |

| Power Rating | Up to 1 W | Typically up to 0.5 W |

| Noise Level | Higher noise | Low noise |

| Cost | Low cost, economical | Higher cost, precision component |

| Applications | General purpose, consumer electronics | Precision circuits, measuring instruments |

| Stability and Reliability | Moderate stability | High stability and long-term reliability |

Introduction to Thick Film and Thin Film Resistors

Thick film resistors consist of a ceramic substrate with a resistive paste applied and fired at high temperatures, offering cost-effective solutions with high power ratings and wide resistance ranges. Thin film resistors utilize a sputtered metal or metal alloy layer on an insulating substrate, providing superior precision, stability, and low noise characteristics ideal for high-frequency applications. Your choice between these resistors depends on requirements for tolerance, temperature coefficient, and application environment.

Construction and Manufacturing Processes

Thick film resistors are typically made by screen-printing a paste of conductive material onto a ceramic substrate, followed by firing at high temperatures to form a solid resistor layer. Thin film resistors use sputtering or evaporation techniques to deposit a thin layer of resistive metal alloy onto an insulating substrate, which is then patterned using photolithography and etching processes. The manufacturing process of thick film resistors is generally less expensive and more suitable for high-volume production, while thin film resistors offer higher precision and stability due to their controlled deposition and minimal layer thickness.

Key Material Differences

Thick film resistors are typically made by screen-printing a conductive paste composed of metal oxides and glass onto a ceramic substrate, resulting in a robust and cost-effective component. Thin film resistors use a much thinner layer of metal, often nickel-chromium or tantalum nitride, deposited by sputtering or evaporation on a substrate, providing superior precision and stability. Your choice between the two depends on the required tolerance, power rating, and environmental stability needed for the application.

Electrical Performance Comparison

Thick film resistors exhibit higher noise levels and larger tolerance ranges compared to thin film resistors, which deliver superior accuracy and lower temperature coefficients. Thin film resistors provide better stability and precision, making them ideal for high-frequency and sensitive electronic applications. Your choice between thick and thin film resistors depends on the required electrical performance, with thin films favored for critical circuits demanding minimal variance.

Tolerance and Accuracy

Thick film resistors typically offer tolerance levels around +-1% to +-5%, making them suitable for general-purpose applications where high precision is not critical. Thin film resistors provide superior accuracy with tolerances as tight as +-0.1% or better, enabling precise performance in high-frequency and low-noise circuits. The manufacturing process of thin film resistors allows for greater control over resistance values, resulting in enhanced stability and lower temperature coefficients compared to thick film counterparts.

Power Rating and Size Considerations

Thick film resistors typically offer higher power ratings, ranging from 0.125W to 5W, making them suitable for applications requiring greater power dissipation, while thin film resistors generally handle lower power levels, usually up to 0.5W. The physical size of thick film resistors tends to be larger due to their construction and power handling capabilities, whereas thin film resistors are favored for their compact size and precision in size-constrained electronic designs. Power rating and size considerations directly influence component selection in high-density circuit boards and power-sensitive applications.

Temperature Coefficient and Stability

Thick film resistors typically exhibit a higher temperature coefficient of resistance (TCR), often around +-100 to +-200 ppm/degC, which can lead to greater resistance variation with temperature changes compared to thin film resistors. Thin film resistors offer superior stability with lower TCR values, generally between +-5 to +-25 ppm/degC, resulting in better performance in precision applications and enhanced long-term reliability. The enhanced temperature stability and resistance tolerance of thin film resistors make them ideal for demanding environments requiring minimal drift and consistent electrical characteristics.

Typical Applications and Use Cases

Thick film resistors are widely used in power management, automotive electronics, and general-purpose applications due to their robustness and cost-effectiveness. Thin film resistors excel in precision instrumentation, aerospace, and medical devices where high accuracy and low noise are critical. Both types support surface mount technology but differ in performance, making thick film ideal for high power and thin film preferable for high precision environments.

Cost and Availability

Thick film resistors generally cost less due to simpler manufacturing processes and widespread production, making them readily available for most electronic applications. Thin film resistors, while more expensive, offer higher precision and stability, often limiting their use to specialized or high-performance circuits. Your choice depends on budget constraints and the required resistor tolerance and reliability.

Choosing the Right Resistor for Your Project

Thick film resistors offer cost-effective solutions with high power ratings and durability, making them ideal for industrial and high-temperature environments. Thin film resistors provide superior accuracy, stability, and low noise, suitable for precision electronic circuits such as instrumentation and communication devices. Evaluating factors like tolerance, power dissipation, frequency response, and environmental conditions will guide the selection of the appropriate resistor for your specific application.

Thick Film Resistor vs Thin Film Resistor Infographic

libmatt.com

libmatt.com