SIP (Single Inline Package) offers a compact design with pins arranged in a single row, enabling easier insertion into circuit boards with limited space, while DIP (Dual Inline Package) features two parallel rows of pins that provide better stability and are commonly used for through-hole mounting. Your choice between SIP and DIP packages depends on the specific layout requirements and space constraints of your electronic project.

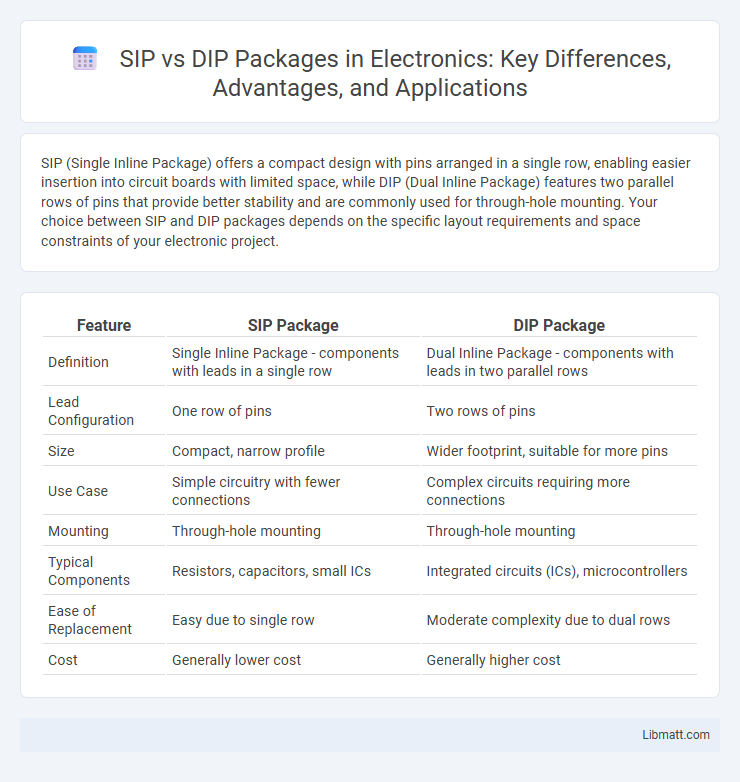

Table of Comparison

| Feature | SIP Package | DIP Package |

|---|---|---|

| Definition | Single Inline Package - components with leads in a single row | Dual Inline Package - components with leads in two parallel rows |

| Lead Configuration | One row of pins | Two rows of pins |

| Size | Compact, narrow profile | Wider footprint, suitable for more pins |

| Use Case | Simple circuitry with fewer connections | Complex circuits requiring more connections |

| Mounting | Through-hole mounting | Through-hole mounting |

| Typical Components | Resistors, capacitors, small ICs | Integrated circuits (ICs), microcontrollers |

| Ease of Replacement | Easy due to single row | Moderate complexity due to dual rows |

| Cost | Generally lower cost | Generally higher cost |

Introduction to SIP and DIP Packages

SIP (Single Inline Package) and DIP (Dual Inline Package) are common types of integrated circuit packaging used in electronic components. SIP packages feature a single row of pins extending from one side of the package, optimizing space for linear configurations, while DIP packages have two parallel rows of pins on either side, enabling stable insertion into through-hole PCB sockets. SIP is typically used for modules like resistors or memory, whereas DIP is favored for microcontrollers and ICs requiring easy manual handling and soldering.

What is a SIP (Single In-Line Package)?

A SIP (Single In-Line Package) is a type of electronic component packaging where all pins are arranged in a single row, facilitating easy insertion into a PCB or breadboard. This design simplifies circuit assembly and is commonly used for resistors, diodes, and some ICs requiring a compact footprint. Understanding the differences between SIP and DIP packages helps optimize your hardware design for space and functionality.

What is a DIP (Dual In-Line Package)?

A Dual In-Line Package (DIP) is a widely used electronic component housing with two parallel rows of pins designed for through-hole mounting on printed circuit boards (PCBs). DIP packages facilitate easy manual soldering and prototyping due to their standardized pin spacing and shape, making them ideal for microcontrollers, memory chips, and other integrated circuits. Understanding DIP packaging helps you select the appropriate format for robust, reliable PCB assembly and seamless integration with socketed or pin-based hardware.

Key Differences Between SIP and DIP Packages

SIP (Single Inline Package) and DIP (Dual Inline Package) differ primarily in their pin configuration; SIP features a single row of pins while DIP has two parallel rows, allowing for more connectivity in the same footprint. DIPs are commonly used in through-hole mounting applications, providing strong mechanical stability, whereas SIPs are often favored in space-constrained designs due to their compact and linear pin arrangement. Thermal performance also varies, with DIP packages typically offering better heat dissipation due to their larger surface area compared to SIPs.

Advantages of SIP Packages

SIP (System-in-Package) packages offer significant advantages such as reduced PCB footprint and improved performance by integrating multiple ICs into a single module, which enhances signal integrity and minimizes latency. You benefit from simpler assembly processes and better thermal management compared to DIP (Dual In-line Package) configurations, making SIP ideal for compact, high-density electronics. These advantages contribute to more efficient designs, lower manufacturing costs, and enhanced device reliability.

Advantages of DIP Packages

Dual In-line Package (DIP) components simplify manual handling and prototyping due to their through-hole mounting and larger pin spacing. Their robust mechanical connection enhances durability and heat dissipation, making them ideal for breadboarding and repair-friendly circuit design. DIP packages also support easy socketing, reducing the risk of damage during insertion and removal compared to Surface Mount Devices (SMDs) like SIP packages.

Common Applications of SIP Packages

SIP (System-in-Package) packages are widely used in compact consumer electronics, such as smartphones, wearables, and IoT devices, due to their high integration density and efficient space utilization. They are also prevalent in automotive electronics for advanced driver-assistance systems (ADAS) and in medical devices requiring miniaturized, multifunctional components. Compared to DIP (Dual In-line Package), SIP offers superior performance in applications where size, weight, and power consumption are critical factors.

Common Applications of DIP Packages

DIP (Dual In-line Package) packages are commonly used in through-hole mounting for prototyping, microcontrollers, and integrated circuits in consumer electronics. They offer ease of manual soldering and replacement, making them ideal for educational kits and early-stage product development. Your projects benefit from DIP packages when durability and straightforward assembly are essential in environments like industrial controls and legacy hardware systems.

SIP vs DIP: Suitability for Modern Electronics

System in Package (SIP) and Dual Inline Package (DIP) differ significantly in suitability for modern electronics; SIP offers higher integration by combining multiple active and passive components into a single compact module, ideal for space-constrained and high-performance applications like IoT devices and smartphones. DIP, with its larger size and discrete pin layout, remains more suitable for prototyping, through-hole applications, and simpler circuit designs where ease of handling and repair are prioritized. Modern electronics increasingly favor SIP technology due to its reduced footprint, improved electrical performance, and enhanced reliability in complex, miniaturized circuits.

Choosing the Right Package for Your Project

Selecting between SIP (Single In-line Package) and DIP (Dual In-line Package) depends on your project's space constraints, circuit complexity, and ease of assembly. SIPs offer a more compact footprint, ideal for saving space in vertical mounting applications, while DIPs provide simpler prototyping and compatibility with standard breadboards and sockets. Your choice should balance the need for efficient layout and ease of maintenance to optimize performance and manufacturing efficiency.

SIP vs DIP Package Infographic

libmatt.com

libmatt.com