Multilayer ceramic capacitors offer low equivalent series resistance (ESR) and excellent high-frequency performance, making them ideal for decoupling and filtering applications. Electrolytic capacitors provide higher capacitance values and are suitable for bulk energy storage and smoothing power supply voltage fluctuations in your circuits.

Table of Comparison

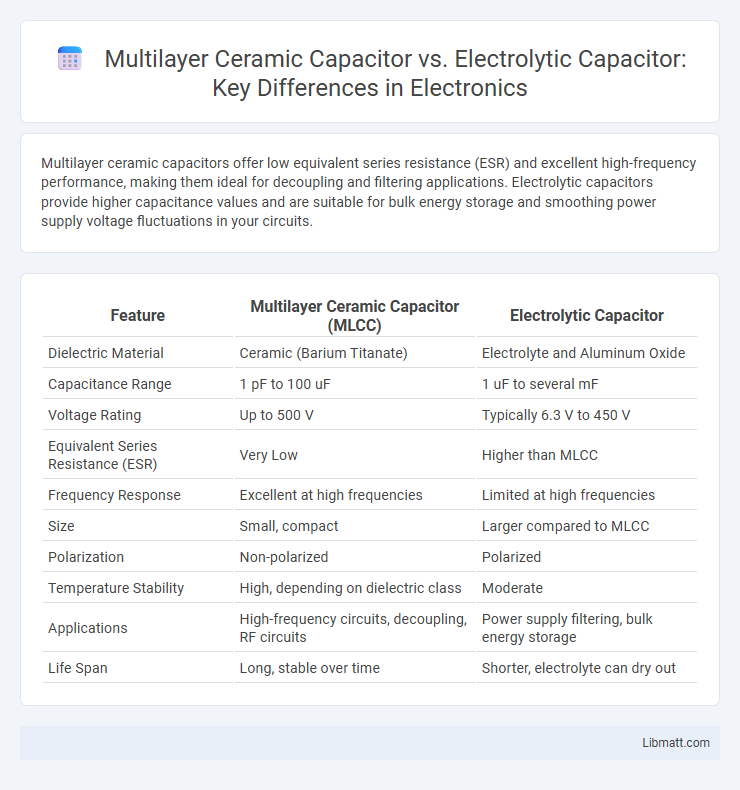

| Feature | Multilayer Ceramic Capacitor (MLCC) | Electrolytic Capacitor |

|---|---|---|

| Dielectric Material | Ceramic (Barium Titanate) | Electrolyte and Aluminum Oxide |

| Capacitance Range | 1 pF to 100 uF | 1 uF to several mF |

| Voltage Rating | Up to 500 V | Typically 6.3 V to 450 V |

| Equivalent Series Resistance (ESR) | Very Low | Higher than MLCC |

| Frequency Response | Excellent at high frequencies | Limited at high frequencies |

| Size | Small, compact | Larger compared to MLCC |

| Polarization | Non-polarized | Polarized |

| Temperature Stability | High, depending on dielectric class | Moderate |

| Applications | High-frequency circuits, decoupling, RF circuits | Power supply filtering, bulk energy storage |

| Life Span | Long, stable over time | Shorter, electrolyte can dry out |

Introduction to Capacitor Types

Multilayer Ceramic Capacitors (MLCCs) consist of multiple layers of ceramic dielectric material and metal electrodes, offering high capacitance in a small, stable package ideal for high-frequency applications. Electrolytic Capacitors utilize an electrolyte-soaked paper or film between conductive plates, providing large capacitance values but with larger size and lower frequency response. These fundamental differences influence their usage in electronic circuits, where MLCCs excel in compact, surface-mount designs and electrolytic capacitors are preferred for bulk energy storage and power filtering.

Overview of Multilayer Ceramic Capacitors

Multilayer Ceramic Capacitors (MLCCs) consist of multiple alternating layers of ceramic dielectric and metal electrodes, offering high capacitance in a compact form factor. Known for their low equivalent series resistance (ESR) and excellent frequency response, MLCCs are widely used in high-frequency applications and surface-mount technology. Their reliability and stability under varying temperatures and voltages make them ideal for decoupling and filtering in electronic circuits.

Overview of Electrolytic Capacitors

Electrolytic capacitors feature a higher capacitance per volume compared to multilayer ceramic capacitors (MLCCs), making them ideal for applications requiring large capacitance such as power supply filtering and audio circuits. They use an electrolyte as one of the plates, with aluminum or tantalum as the anode material, which results in a polarized component with voltage and polarity sensitivity. Electrolytic capacitors generally have higher equivalent series resistance (ESR) and lower frequency response than MLCCs but excel in energy storage and smoothing applications due to their robust capacitance range.

Construction and Material Differences

Multilayer Ceramic Capacitors (MLCCs) consist of multiple alternating layers of ceramic dielectric and metal electrodes, providing a compact, stable structure with excellent high-frequency performance. Electrolytic capacitors use an aluminum or tantalum anode coated with an oxide layer as the dielectric, combined with a liquid or solid electrolyte, resulting in higher capacitance values but less stability and a larger physical size. Understanding these construction and material differences helps you select the right capacitor type to optimize your electronic circuit's performance and longevity.

Capacitance Range and Voltage Ratings

Multilayer Ceramic Capacitors (MLCCs) typically offer capacitance values ranging from picofarads (pF) up to several microfarads (uF), with voltage ratings often between 6.3V and 500V, making them ideal for high-frequency, low-voltage applications. Electrolytic Capacitors provide much higher capacitance, generally from 1uF to several thousand microfarads, with voltage ratings from 6.3V up to 450V, suited for bulk energy storage and power supply filtering in your circuits. Choosing the right capacitor depends on matching the required capacitance and voltage rating to your specific electronic needs.

Performance in High-Frequency Applications

Multilayer ceramic capacitors (MLCCs) exhibit superior performance in high-frequency applications due to their low equivalent series resistance (ESR) and low inductance, enabling faster response times and minimal signal loss. Electrolytic capacitors typically have higher ESR and inductance, leading to increased impedance and reduced efficiency at frequencies above 100 kHz. The dielectric properties of MLCCs make them ideal for RF circuits, filtering, and decoupling tasks where stable capacitance and low noise are critical.

Temperature Stability and Reliability

Multilayer Ceramic Capacitors (MLCCs) exhibit superior temperature stability due to their ceramic dielectric, maintaining consistent capacitance across a wide temperature range, typically from -55degC to +125degC. Electrolytic capacitors, however, experience significant capacitance variance and higher Equivalent Series Resistance (ESR) at elevated temperatures, limiting their reliability under thermal stress. Choosing MLCCs enhances your circuit's performance stability and long-term reliability in temperature-sensitive applications.

Lifespan and Failure Modes

Multilayer ceramic capacitors (MLCCs) typically offer longer lifespans, often exceeding 10,000 hours under rated conditions, due to their solid ceramic dielectric, which resists degradation over time, while electrolytic capacitors usually have shorter lifespans around 1,000 to 5,000 hours because their liquid electrolyte can evaporate or leak. MLCCs predominantly fail through dielectric cracking or electrode degradation caused by mechanical stress or thermal cycling, leading to reduced capacitance or open circuits, whereas electrolytic capacitors frequently fail due to electrolyte drying, internal short circuits, or swelling from voltage stress and temperature effects. Understanding these distinct failure mechanisms and lifespan characteristics is crucial for selecting the appropriate capacitor type in high-reliability electronic applications.

Typical Applications in Electronic Circuits

Multilayer Ceramic Capacitors (MLCCs) are commonly used in high-frequency applications such as decoupling, filtering, and timing circuits due to their low equivalent series resistance (ESR) and high stability. Electrolytic capacitors are preferred in power supply circuits, audio equipment, and bulk energy storage where high capacitance values and voltage handling are critical despite their larger size and higher ESR. Both capacitor types play essential roles in smoothing voltage fluctuations, but MLCCs excel in compact, high-frequency environments while electrolytics dominate in applications needing large capacitance in lower-frequency or high-current scenarios.

Choosing the Right Capacitor for Your Project

Multilayer Ceramic Capacitors (MLCCs) offer low Equivalent Series Resistance (ESR), high frequency performance, and compact size, making them ideal for high-speed circuits and surface-mount applications. Electrolytic Capacitors provide higher capacitance values and better energy storage, suitable for power supply filtering and audio applications requiring bulk capacitance. Your choice depends on circuit requirements such as capacitance, voltage rating, size constraints, and frequency response to ensure optimal performance and reliability.

Multilayer Ceramic Capacitor vs Electrolytic Capacitor Infographic

libmatt.com

libmatt.com