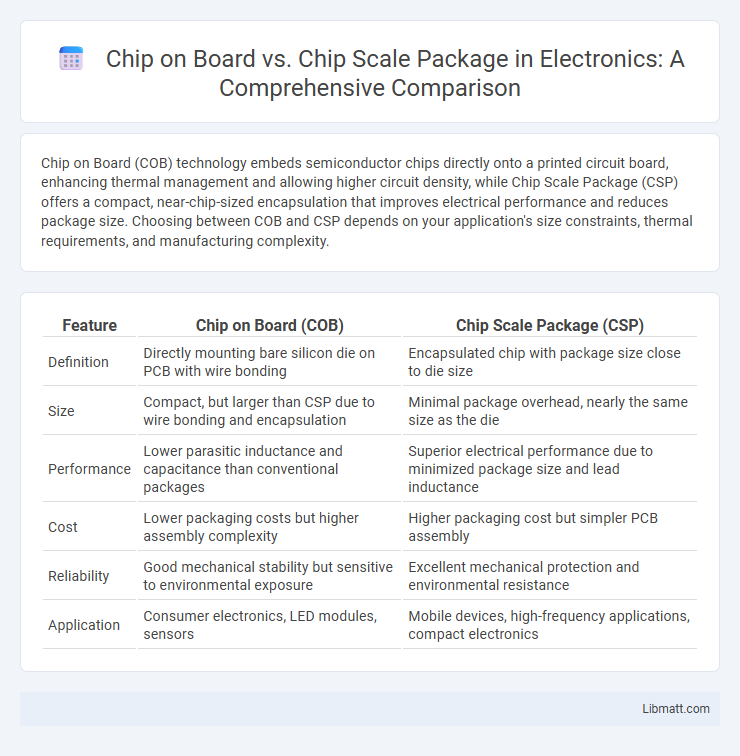

Chip on Board (COB) technology embeds semiconductor chips directly onto a printed circuit board, enhancing thermal management and allowing higher circuit density, while Chip Scale Package (CSP) offers a compact, near-chip-sized encapsulation that improves electrical performance and reduces package size. Choosing between COB and CSP depends on your application's size constraints, thermal requirements, and manufacturing complexity.

Table of Comparison

| Feature | Chip on Board (COB) | Chip Scale Package (CSP) |

|---|---|---|

| Definition | Directly mounting bare silicon die on PCB with wire bonding | Encapsulated chip with package size close to die size |

| Size | Compact, but larger than CSP due to wire bonding and encapsulation | Minimal package overhead, nearly the same size as the die |

| Performance | Lower parasitic inductance and capacitance than conventional packages | Superior electrical performance due to minimized package size and lead inductance |

| Cost | Lower packaging costs but higher assembly complexity | Higher packaging cost but simpler PCB assembly |

| Reliability | Good mechanical stability but sensitive to environmental exposure | Excellent mechanical protection and environmental resistance |

| Application | Consumer electronics, LED modules, sensors | Mobile devices, high-frequency applications, compact electronics |

Introduction to Chip on Board (COB) and Chip Scale Package (CSP)

Chip on Board (COB) technology involves directly mounting bare semiconductor chips onto a printed circuit board (PCB), enabling miniaturized device assembly and improved electrical performance. Chip Scale Package (CSP) refers to a compact packaging method where the package size closely matches the die size, providing enhanced electrical characteristics and efficient thermal management. Both COB and CSP technologies are essential in modern electronics for optimizing space, performance, and manufacturing costs in devices such as smartphones, medical equipment, and automotive electronics.

Defining Chip on Board (COB) Technology

Chip on Board (COB) technology involves directly mounting bare semiconductor chips onto a printed circuit board, allowing for compact, high-density packaging and enhanced electrical performance. Unlike Chip Scale Package (CSP) that encloses the chip in a miniature package, COB exposes the chip, which is wire-bonded and encapsulated with epoxy resin for protection. Your choice of COB technology can optimize space and thermal management in applications requiring miniaturization and reliability.

Understanding Chip Scale Package (CSP) Technology

Chip Scale Package (CSP) technology offers a compact and efficient solution by directly mounting the semiconductor die onto the package substrate, minimizing size and enhancing electrical performance. Unlike traditional Chip on Board (COB) methods, CSP provides superior mechanical protection and better thermal management through standardized packaging. Your design benefits from improved reliability and easier integration in high-density electronic applications with CSP technology.

Key Differences Between COB and CSP

Chip on Board (COB) integrates bare semiconductor dies directly onto a printed circuit board, providing excellent thermal management and compact design with wire bonding or flip-chip techniques. Chip Scale Package (CSP) encapsulates the die within a miniature package that closely matches the chip size, offering enhanced mechanical protection and ease of surface mounting comparable to traditional IC packages. Key differences include COB's direct die mounting versus CSP's encapsulated packaging, COB's superior heat dissipation, and CSP's standardized form factor for automated assembly processes.

Advantages of Chip on Board (COB)

Chip on Board (COB) offers superior thermal performance and enhanced electrical conductivity by directly mounting the semiconductor die on the substrate, reducing parasitic inductance and capacitance. COB enables higher component density and improved reliability due to fewer interconnections compared to Chip Scale Package (CSP), making it ideal for compact and high-performance applications. Your designs benefit from lower manufacturing costs and better heat dissipation, which lead to increased lifespan and consistent performance.

Benefits of Chip Scale Package (CSP)

Chip Scale Package (CSP) offers superior miniaturization compared to traditional Chip on Board (COB) technology, enabling higher component density on printed circuit boards. CSP enhances electrical performance through shorter interconnections, reducing parasitic inductance and capacitance, which improves signal integrity and speed. Additionally, CSP provides better mechanical reliability and thermal management, resulting in increased device lifespan and consistent performance in high-stress environments.

Common Applications of COB and CSP

Chip on Board (COB) technology is widely used in LED lighting, automotive electronics, and compact consumer devices due to its efficient thermal management and high-density mounting capabilities. Chip Scale Package (CSP) finds common applications in mobile phones, wearable technology, and high-performance computing where miniaturization and electrical performance are critical. Both COB and CSP enable advanced electronic designs but serve different market segments based on size constraints and power dissipation requirements.

Performance Comparison: COB vs CSP

Chip on Board (COB) technology offers superior thermal dissipation and enhanced electrical performance compared to Chip Scale Package (CSP) due to direct bonding of the silicon die onto the substrate. COB enables shorter interconnect paths, reducing parasitic inductance and capacitance, which improves signal integrity and overall device speed. Your choice between COB and CSP should consider COB's advantages in high-frequency and high-power applications where performance optimization is critical.

Cost Considerations: COB vs CSP

Chip on Board (COB) technology generally offers lower overall manufacturing costs compared to Chip Scale Package (CSP) due to simpler assembly processes and fewer packaging steps. COB reduces material expenses by directly bonding the bare die onto the substrate, eliminating the need for complex encapsulation found in CSP. However, CSP provides advantages in miniaturization and thermal performance, which may justify higher costs in applications requiring compact and efficient designs.

Future Trends in Semiconductor Packaging Technologies

Chip on Board (CoB) technology advances with finer pitch wiring and improved thermal management for enhanced device performance and miniaturization. Chip Scale Package (CSP) evolves through heterogeneous integration and embedded die solutions, enabling higher I/O density and reduced parasitic effects. Emerging trends emphasize 3D packaging, system-in-package (SiP) designs, and advanced materials to drive next-generation semiconductor device efficiency and scalability.

Chip on Board vs Chip Scale Package Infographic

libmatt.com

libmatt.com