Wet tantalum capacitors offer higher capacitance and better volumetric efficiency with improved performance under surge currents compared to solid tantalum capacitors, making them ideal for applications needing higher reliability and capacitance stability. Your choice depends on the specific requirements for leakage current, size, and operating conditions, as solid tantalum capacitors are typically preferred for their lower ESR and better frequency response.

Table of Comparison

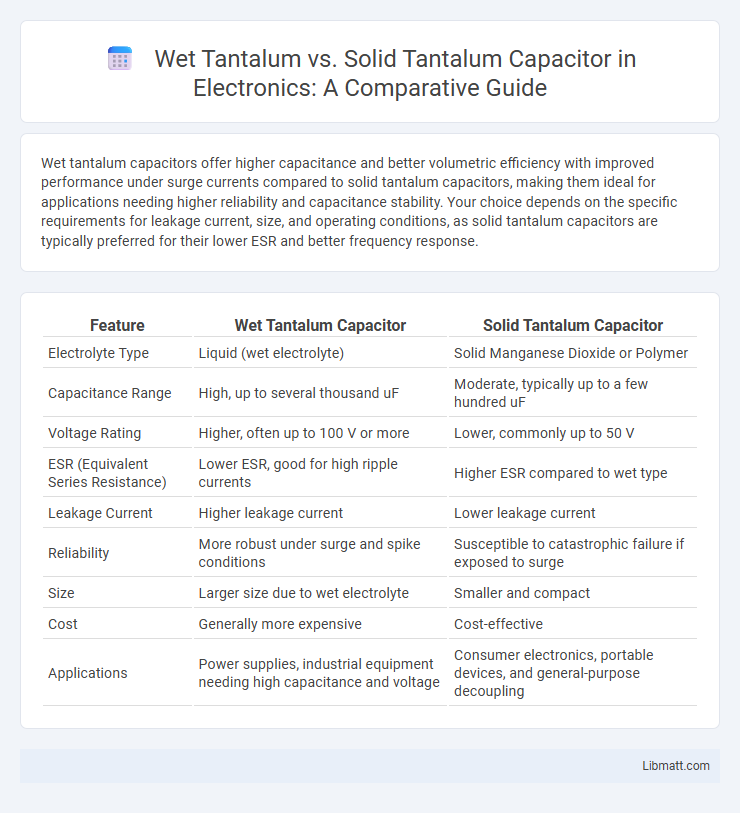

| Feature | Wet Tantalum Capacitor | Solid Tantalum Capacitor |

|---|---|---|

| Electrolyte Type | Liquid (wet electrolyte) | Solid Manganese Dioxide or Polymer |

| Capacitance Range | High, up to several thousand uF | Moderate, typically up to a few hundred uF |

| Voltage Rating | Higher, often up to 100 V or more | Lower, commonly up to 50 V |

| ESR (Equivalent Series Resistance) | Lower ESR, good for high ripple currents | Higher ESR compared to wet type |

| Leakage Current | Higher leakage current | Lower leakage current |

| Reliability | More robust under surge and spike conditions | Susceptible to catastrophic failure if exposed to surge |

| Size | Larger size due to wet electrolyte | Smaller and compact |

| Cost | Generally more expensive | Cost-effective |

| Applications | Power supplies, industrial equipment needing high capacitance and voltage | Consumer electronics, portable devices, and general-purpose decoupling |

Introduction to Tantalum Capacitors

Tantalum capacitors, including wet tantalum and solid tantalum types, are known for their high capacitance-to-volume ratio and stability in electronic circuits. Wet tantalum capacitors use a liquid electrolyte, offering higher voltage ratings and better performance in harsh environments, while solid tantalum capacitors utilize a solid manganese dioxide or polymer electrolyte, providing lower ESR and improved reliability for compact applications. Understanding the differences in construction and electrical characteristics can help you select the optimal tantalum capacitor for your specific electronic design needs.

What are Wet Tantalum Capacitors?

Wet tantalum capacitors contain a liquid electrolyte that significantly enhances their capacitance and voltage ratings compared to solid tantalum capacitors. These capacitors exhibit lower equivalent series resistance (ESR) and improved performance in high ripple current applications, making them suitable for power supply filtering and industrial electronics. Their construction involves a tantalum anode, dielectric layer, and a sealed body filled with a conductive electrolyte to maintain stability under varying operating conditions.

What are Solid Tantalum Capacitors?

Solid tantalum capacitors use a manganese dioxide or conductive polymer as the cathode material, offering superior stability, reliability, and smaller size compared to wet tantalum capacitors. These capacitors feature a solid electrolyte, which eliminates issues related to leakage and evaporation commonly found in wet tantalum capacitors. Solid tantalum capacitors are widely employed in applications requiring high capacitance per volume, low ESR, and excellent performance under varying temperatures and frequencies.

Key Differences Between Wet and Solid Tantalum Capacitors

Wet tantalum capacitors use a liquid electrolyte, offering higher voltage ratings and better high-frequency performance compared to solid tantalum capacitors, which use a manganese dioxide or conductive polymer electrolyte. Solid tantalum capacitors typically provide lower Equivalent Series Resistance (ESR) and greater reliability in smaller sizes, making them ideal for compact electronic devices. The key differences lie in their electrolyte state, voltage ratings, ESR values, and suitability for different applications such as power supply filtering or signal processing.

Performance Characteristics Comparison

Wet tantalum capacitors exhibit superior voltage handling and higher capacitance stability under extreme conditions compared to solid tantalum capacitors, which are known for their lower equivalent series resistance (ESR) and fast response times. Your application may benefit from wet tantalum's enhanced surge current tolerance and robust temperature performance, while solid tantalum capacitors excel in compact, low-noise circuits requiring quick charge-discharge cycles. Careful evaluation of operating voltage, ripple current, and failure mode is essential to optimize capacitor selection based on these distinct performance characteristics.

Applications of Wet Tantalum Capacitors

Wet tantalum capacitors are widely used in high-reliability applications such as aerospace, military, and medical devices due to their superior performance in high-voltage and high-temperature environments. These capacitors offer excellent capacitance stability and longer life under harsh conditions, making them ideal for power supply filtering and energy storage in mission-critical systems. Your designs benefit from enhanced durability and reliability when incorporating wet tantalum capacitors in extreme operating conditions.

Applications of Solid Tantalum Capacitors

Solid tantalum capacitors are widely used in portable electronics, automotive systems, and aerospace equipment due to their high capacitance per volume and excellent reliability. These capacitors perform well in low-voltage applications, such as power supply filtering, decoupling, and timing circuits, where stable capacitance and low Equivalent Series Resistance (ESR) are critical. Their solid electrolyte construction offers superior mechanical robustness and longer life compared to wet tantalum capacitors, making them ideal for harsh environmental conditions.

Advantages and Disadvantages

Wet tantalum capacitors offer higher capacitance and superior performance at elevated temperatures compared to solid tantalum capacitors, making them ideal for high-reliability applications such as aerospace and military electronics. However, they are bulkier, more expensive, and less resistant to mechanical shock, which limits their use in compact consumer devices. Solid tantalum capacitors provide better volumetric efficiency and lower equivalent series resistance (ESR), enabling stable operation in space-constrained circuits, but they are more prone to catastrophic failure under surge currents or voltage spikes.

Reliability and Lifespan Considerations

Wet tantalum capacitors offer enhanced reliability in high-voltage and high-temperature applications due to their liquid electrolyte, which provides better self-healing properties and longer operational lifespan compared to solid tantalum capacitors. Solid tantalum capacitors, while smaller and more stable under normal conditions, are more susceptible to catastrophic failure if subjected to voltage spikes or surge currents, limiting their lifespan in harsh environments. The choice between wet and solid tantalum capacitors significantly impacts device durability, with wet tantalum capacitors preferred for critical, long-life applications requiring robust performance.

Choosing the Right Tantalum Capacitor for Your Design

Wet tantalum capacitors offer higher capacitance and improved voltage stability for demanding applications, while solid tantalum capacitors provide lower equivalent series resistance (ESR) and better performance in high-frequency circuits. Selecting the right tantalum capacitor depends on factors such as operating temperature, voltage requirements, and size constraints, with wet types favoring high-energy storage and solid types excelling in compact, reliable designs. Careful consideration of ripple current capability and environmental conditions ensures optimal performance and longer lifespan in your electronic design.

Wet tantalum vs Solid tantalum capacitor Infographic

libmatt.com

libmatt.com