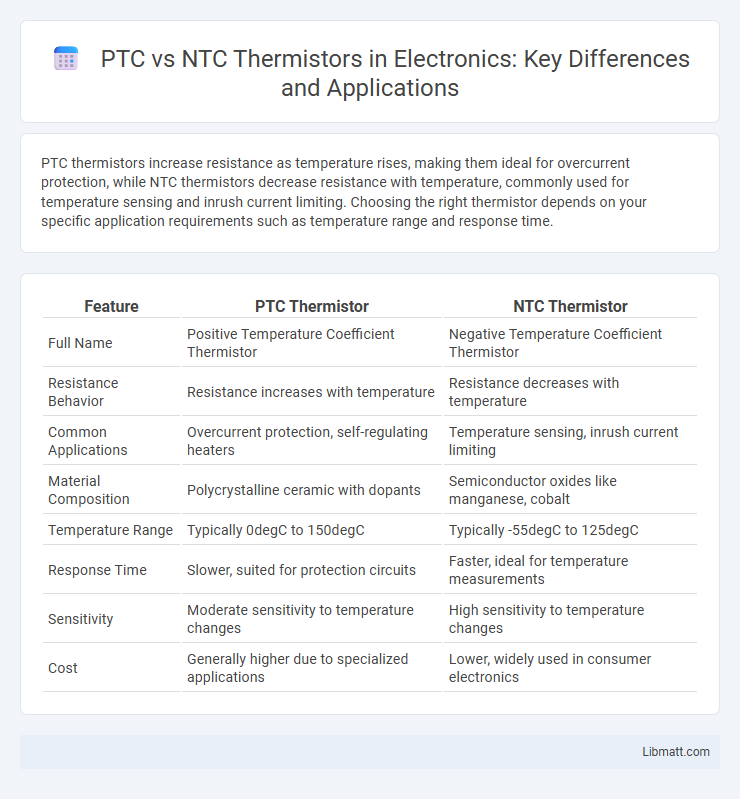

PTC thermistors increase resistance as temperature rises, making them ideal for overcurrent protection, while NTC thermistors decrease resistance with temperature, commonly used for temperature sensing and inrush current limiting. Choosing the right thermistor depends on your specific application requirements such as temperature range and response time.

Table of Comparison

| Feature | PTC Thermistor | NTC Thermistor |

|---|---|---|

| Full Name | Positive Temperature Coefficient Thermistor | Negative Temperature Coefficient Thermistor |

| Resistance Behavior | Resistance increases with temperature | Resistance decreases with temperature |

| Common Applications | Overcurrent protection, self-regulating heaters | Temperature sensing, inrush current limiting |

| Material Composition | Polycrystalline ceramic with dopants | Semiconductor oxides like manganese, cobalt |

| Temperature Range | Typically 0degC to 150degC | Typically -55degC to 125degC |

| Response Time | Slower, suited for protection circuits | Faster, ideal for temperature measurements |

| Sensitivity | Moderate sensitivity to temperature changes | High sensitivity to temperature changes |

| Cost | Generally higher due to specialized applications | Lower, widely used in consumer electronics |

Introduction to Thermistors

Thermistors are temperature-sensitive resistors commonly used for precise temperature measurement and control, classified mainly into PTC (Positive Temperature Coefficient) and NTC (Negative Temperature Coefficient) types. PTC thermistors increase resistance with rising temperature, making them ideal for overcurrent protection and self-regulating heating elements. NTC thermistors decrease resistance as temperature rises, providing high sensitivity and accuracy in temperature sensing applications such as temperature measurement, circuit protection, and temperature compensation.

What is a PTC Thermistor?

A PTC thermistor (Positive Temperature Coefficient) is a type of resistor whose resistance increases significantly as the temperature rises, commonly used for overcurrent protection and self-regulating heating elements. It operates by exhibiting a sharp increase in resistance at a specific temperature threshold, which makes it ideal for applications like resettable fuses and temperature sensing. PTC thermistors are often selected in circuits requiring reliable thermal protection due to their predictable response and durability.

What is an NTC Thermistor?

An NTC thermistor is a temperature-sensitive resistor whose resistance decreases as temperature rises, making it ideal for precise temperature measurement and control. Unlike a PTC thermistor, which increases resistance with temperature, the NTC thermistor provides fast response times and high accuracy in monitoring thermal changes. Understanding the behavior of NTC thermistors can help you select the right component for applications such as temperature sensing, circuit protection, and temperature compensation.

Key Differences Between PTC and NTC Thermistors

PTC thermistors exhibit a positive temperature coefficient, meaning their resistance increases with rising temperature, making them ideal for overcurrent protection and self-regulating heaters. NTC thermistors have a negative temperature coefficient, where resistance decreases as temperature rises, commonly used for temperature sensing and inrush current limiting. Understanding the contrasting resistance-temperature characteristics of PTC and NTC thermistors helps you select the appropriate component for precise temperature measurement or circuit protection applications.

Construction and Materials

PTC thermistors typically use polymer or ceramic materials with a positive temperature coefficient, causing resistance to increase as temperature rises, while NTC thermistors are made from metal oxides with a negative temperature coefficient that decreases resistance with heat. PTC devices often feature a crystalline ceramic composition with dopants, offering self-regulating thermal protection, whereas NTC types are crafted from sintered semiconductor materials optimized for precise temperature sensing. The choice of materials in both thermistor types directly influences their electrical characteristics, stability, and application suitability in temperature measurement and control systems.

Working Principle of PTC Thermistors

PTC thermistors operate based on a positive temperature coefficient, meaning their resistance increases with rising temperature due to reduced charge carrier mobility in the thermistor material. This unique property allows PTC thermistors to function as self-regulating heating elements and overcurrent protection devices by limiting current flow as they heat up. Your applications benefit from the predictable resistance change that provides reliable temperature sensing and circuit protection.

Working Principle of NTC Thermistors

NTC thermistors operate based on the negative temperature coefficient principle, where their resistance decreases as temperature increases, enabling precise temperature measurement and control. Constructed from semiconductor materials, NTC thermistors provide rapid response to temperature changes due to their intrinsic resistive properties. This characteristic makes them ideal for circuit protection, temperature sensing, and thermal management applications.

Applications of PTC Thermistors

PTC thermistors are widely used in applications such as overcurrent protection, temperature sensing, and self-regulating heaters due to their positive temperature coefficient properties. These devices provide reliable circuit protection by increasing resistance sharply when temperatures rise beyond a threshold, effectively limiting current flow. Your electronic systems can benefit from PTC thermistors in motor protection, resettable fuses, and temperature control in appliances.

Applications of NTC Thermistors

NTC thermistors are widely used in temperature sensing and inrush current limiting applications due to their predictable decrease in resistance as temperature rises. They are essential components in electronic devices such as rechargeable battery packs, automotive temperature sensors, HVAC systems, and household appliances for accurate thermal management. The high sensitivity of NTC thermistors allows precise temperature monitoring and control, making them crucial in medical instruments and environmental monitoring equipment.

Choosing the Right Thermistor for Your Application

Selecting the appropriate thermistor depends on the specific requirements of your application, with PTC thermistors offering self-regulating properties ideal for overcurrent protection, while NTC thermistors provide precise temperature measurement and control through their negative temperature coefficient. PTC thermistors increase resistance as temperature rises, making them suitable for resettable fuses and thermal switches, whereas NTC thermistors decrease resistance with temperature, allowing accurate thermal sensing and compensation. Understanding the operational environment, temperature range, and response time is crucial in choosing between PTC and NTC thermistors to ensure optimal performance and reliability.

PTC vs NTC Thermistor Infographic

libmatt.com

libmatt.com