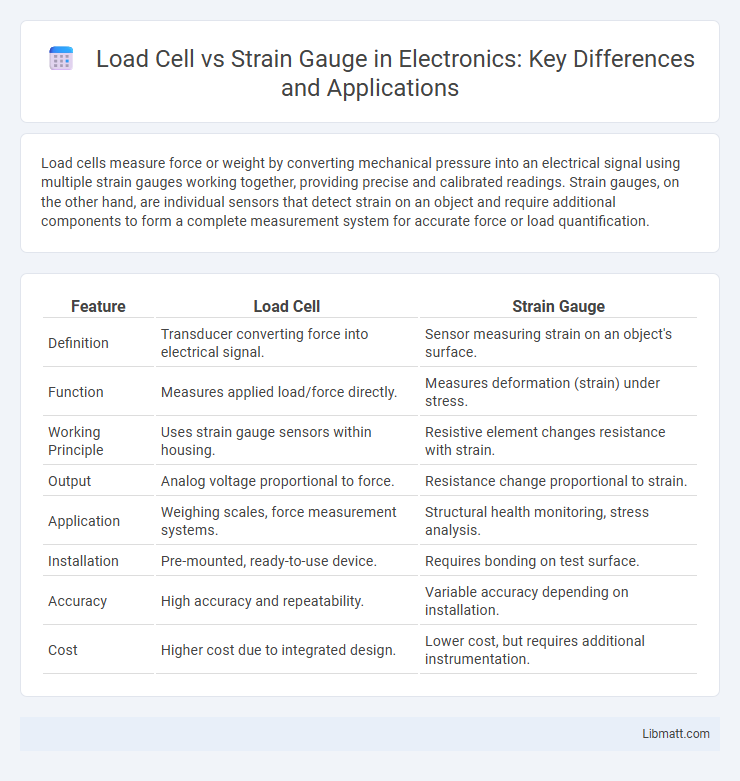

Load cells measure force or weight by converting mechanical pressure into an electrical signal using multiple strain gauges working together, providing precise and calibrated readings. Strain gauges, on the other hand, are individual sensors that detect strain on an object and require additional components to form a complete measurement system for accurate force or load quantification.

Table of Comparison

| Feature | Load Cell | Strain Gauge |

|---|---|---|

| Definition | Transducer converting force into electrical signal. | Sensor measuring strain on an object's surface. |

| Function | Measures applied load/force directly. | Measures deformation (strain) under stress. |

| Working Principle | Uses strain gauge sensors within housing. | Resistive element changes resistance with strain. |

| Output | Analog voltage proportional to force. | Resistance change proportional to strain. |

| Application | Weighing scales, force measurement systems. | Structural health monitoring, stress analysis. |

| Installation | Pre-mounted, ready-to-use device. | Requires bonding on test surface. |

| Accuracy | High accuracy and repeatability. | Variable accuracy depending on installation. |

| Cost | Higher cost due to integrated design. | Lower cost, but requires additional instrumentation. |

Introduction to Load Cells and Strain Gauges

Load cells are precision sensors designed to measure force or weight by converting mechanical pressure into an electrical signal, commonly used in industrial weighing systems. Strain gauges serve as the fundamental sensing elements within load cells, detecting minute deformations in materials by measuring changes in electrical resistance. Understanding the relationship between load cells and strain gauges is crucial for accurately interpreting force measurements in various engineering applications.

Basic Principles of Load Cells

Load cells operate by converting force into an electrical signal using strain gauges bonded to a deformable structure, which changes resistance when subjected to stress. The strain gauge measures minute strain variations caused by the applied load, resulting in a proportional electrical output that accurately reflects the force magnitude. Understanding this core principle helps you select the right load cell for precise weight or force measurement applications.

Fundamental Concepts of Strain Gauges

Strain gauges are sensors that measure strain by converting mechanical deformation into a change in electrical resistance, utilizing the principle that resistance varies with length and cross-sectional area. They consist of a thin metal foil pattern bonded to a backing material, which deforms with the surface it is attached to, allowing precise measurement of strain. Load cells often incorporate strain gauges to convert force or load into an electrical signal, enabling accurate measurement of weight, force, or pressure.

Key Differences Between Load Cells and Strain Gauges

Load cells are complete measurement systems that convert force into an electrical signal, while strain gauges are sensors that measure strain on an object's surface. Load cells typically incorporate multiple strain gauges configured in a Wheatstone bridge to provide accurate force readings and compensate for temperature and motion effects. Your choice depends on whether you need a full force measurement device (load cell) or a component to measure deformation (strain gauge) for custom applications.

Types of Load Cells and Their Applications

Load cells primarily include strain gauge, hydraulic, pneumatic, and capacitive types, with strain gauge load cells being the most widely used for their precision and durability in industrial weighing and force measurement applications. Strain gauge load cells operate by measuring the deformation of a bonded strain gauge under load, making them ideal for applications ranging from aerospace testing to manufacturing process control. Hydraulic load cells suit environments requiring explosion-proof equipment, while pneumatic load cells excel in cleanroom settings where contamination-free measurements are critical.

Varieties of Strain Gauges and Their Uses

Strain gauges come in various types including foil, wire, semiconductor, and fiber optic strain gauges, each designed for specific applications such as foil gauges for structural testing, wire gauges for dynamic measurements, semiconductor gauges for high sensitivity needs, and fiber optic gauges for environments with electromagnetic interference. These varieties enable precise measurement of strain under different conditions, influencing the accuracy of load cells that often incorporate strain gauges as their sensing elements. Your choice of strain gauge affects the performance and suitability of a load cell in applications ranging from industrial weighing to aerospace stress analysis.

Accuracy and Sensitivity: Which Is Better?

Load cells generally offer higher accuracy compared to strain gauges due to their integrated design, which minimizes external interference and ensures consistent measurements. Strain gauges provide superior sensitivity as they directly measure strain variations at a microscopic level, capturing minute changes in deformation. For applications demanding precise load measurement, load cells are preferred, while strain gauges excel in detecting subtle strain differences in materials testing.

Installation and Calibration Comparison

Load cells offer straightforward installation with plug-and-play compatibility and factory calibration, ensuring consistent accuracy out of the box. Strain gauges require meticulous application involving surface preparation, adhesive bonding, and precise wiring, often demanding in-field calibration to achieve reliable measurements. Your choice depends on whether you prioritize ease of setup with pre-calibrated units or custom sensor adaptability with manual calibration processes.

Cost and Maintenance Factors

Load cells generally have higher initial costs due to their integrated design and calibration, while strain gauges are more cost-effective but require additional equipment for installation and signal processing. Maintenance for load cells is minimal since they come pre-assembled and sealed, reducing exposure to environmental damage, whereas strain gauges demand more frequent inspections and careful handling to prevent sensor degradation and signal drift. Economically, load cells offer greater long-term reliability and lower maintenance expenses, making them suitable for industrial applications with stringent accuracy requirements.

Choosing the Right Sensor for Your Application

Choosing the right sensor for your application depends on factors such as accuracy, range, and environmental conditions. Load cells provide precise force measurement and are ideal for higher load capacities, while strain gauges offer flexibility for custom applications and smaller force detection. Consider your specific requirements to ensure optimal performance and reliability from the selected sensor.

Load cell vs Strain gauge Infographic

libmatt.com

libmatt.com