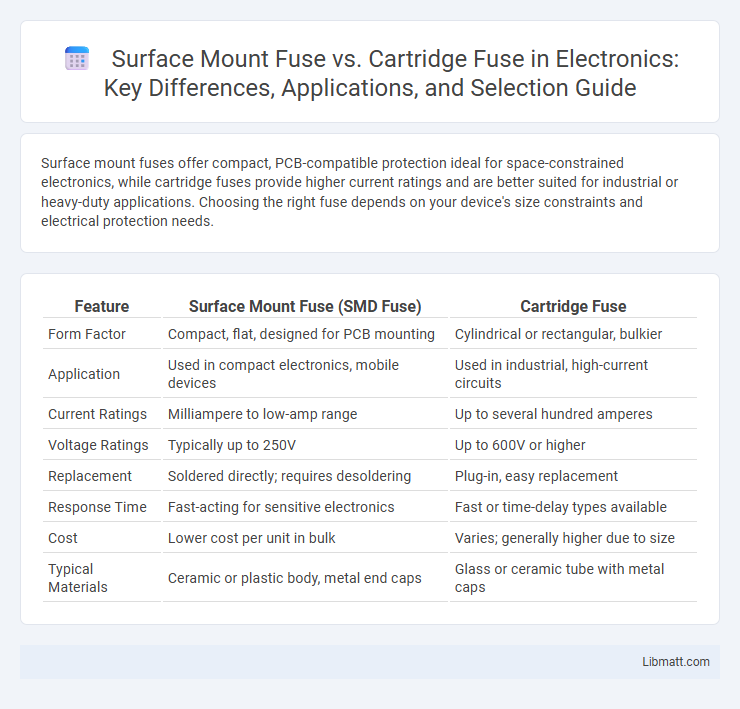

Surface mount fuses offer compact, PCB-compatible protection ideal for space-constrained electronics, while cartridge fuses provide higher current ratings and are better suited for industrial or heavy-duty applications. Choosing the right fuse depends on your device's size constraints and electrical protection needs.

Table of Comparison

| Feature | Surface Mount Fuse (SMD Fuse) | Cartridge Fuse |

|---|---|---|

| Form Factor | Compact, flat, designed for PCB mounting | Cylindrical or rectangular, bulkier |

| Application | Used in compact electronics, mobile devices | Used in industrial, high-current circuits |

| Current Ratings | Milliampere to low-amp range | Up to several hundred amperes |

| Voltage Ratings | Typically up to 250V | Up to 600V or higher |

| Replacement | Soldered directly; requires desoldering | Plug-in, easy replacement |

| Response Time | Fast-acting for sensitive electronics | Fast or time-delay types available |

| Cost | Lower cost per unit in bulk | Varies; generally higher due to size |

| Typical Materials | Ceramic or plastic body, metal end caps | Glass or ceramic tube with metal caps |

Introduction to Surface Mount and Cartridge Fuses

Surface mount fuses are compact, designed for direct soldering onto printed circuit boards, offering excellent space efficiency and fast response to overcurrent conditions. Cartridge fuses consist of a cylindrical ceramic or glass body with metal end caps, typically used in higher current applications and easily replaceable in fuse holders. Both fuse types provide crucial circuit protection but differ in form factor, mounting, and typical use cases in electronic and electrical systems.

What is a Surface Mount Fuse?

A surface mount fuse is a compact protective device designed for circuit boards, soldered directly onto the PCB to safeguard electronic components from overcurrent damage. Unlike cartridge fuses, which are cylindrical and replaceable, surface mount fuses are integrated into the circuitry for space-saving and automated assembly benefits. These fuses offer precise current ratings and fast response times, making them ideal for modern electronic devices requiring reliable circuit protection.

What is a Cartridge Fuse?

A cartridge fuse is a cylindrical electrical safety device designed to protect circuits from overcurrent by breaking the circuit when excessive current flows through it. It consists of a metal wire or strip enclosed in a non-combustible tube, typically made of ceramic or glass, providing reliable and fast response to prevent damage to electrical components. Cartridge fuses are widely used in industrial applications and electrical panels due to their high interrupting capacity and ease of replacement.

Key Differences Between Surface Mount and Cartridge Fuses

Surface mount fuses are designed for compact, automated PCB assembly and provide fast response times in low-current applications, while cartridge fuses handle higher currents with robust, replaceable designs suitable for industrial and electrical distribution systems. Surface mount fuses typically feature smaller sizes and standardized packaging for seamless integration in modern electronics, whereas cartridge fuses offer greater power dissipation and are often housed in protective casings for manual replacement. Understanding these key differences helps you select the appropriate fuse type based on circuit requirements, size constraints, and protection needs.

Application Areas: Surface Mount vs Cartridge Fuses

Surface mount fuses are primarily used in compact, high-density electronic devices such as smartphones, laptops, and circuit boards where space-saving and automated assembly are critical. Cartridge fuses are commonly employed in industrial machinery, electrical panels, and automotive systems that require higher current ratings and robust protection against overloads and short circuits. The choice between surface mount and cartridge fuses depends on the specific application's size constraints, current requirements, and environmental conditions.

Advantages of Surface Mount Fuses

Surface mount fuses offer precise current protection in compact electronic circuits, enabling seamless integration on printed circuit boards (PCBs) for space-saving designs. These fuses provide faster response times and lower resistance compared to cartridge fuses, improving overall circuit reliability and performance. Their automated assembly compatibility enhances manufacturing efficiency and reduces labor costs in high-volume production environments.

Advantages of Cartridge Fuses

Cartridge fuses offer superior current interruption capacity and higher fault tolerance compared to surface mount fuses, making them ideal for protecting high-power electrical circuits. Their robust construction allows for easy replacement and customization to specific voltage and current ratings, enhancing system reliability. Additionally, cartridge fuses provide better thermal performance and longer lifespan under heavy load conditions.

Limitations of Surface Mount and Cartridge Fuses

Surface mount fuses have size constraints that limit their current and voltage ratings, making them less suitable for high-power applications compared to cartridge fuses, which can handle higher fault currents and offer greater interrupting capacity. Cartridge fuses, while robust, tend to be bulkier and require more space on your circuit board, potentially complicating design in compact electronics. Surface mount fuses also have limited thermal dissipation capabilities, which can affect reliability under heavy load conditions.

How to Choose Between Surface Mount and Cartridge Fuses

Selecting between surface mount and cartridge fuses depends primarily on your device's size, current rating, and environmental conditions. Surface mount fuses are ideal for compact electronics requiring automated assembly and low-profile protection, while cartridge fuses suit higher current applications with easier replacement needs and robust durability. Assess your circuit's space constraints, electrical load, and ease of maintenance to determine the best fuse type for your protection requirements.

Future Trends in Fuse Technology

Surface mount fuses and cartridge fuses are evolving with advancements in materials and miniaturization, enabling higher current ratings and faster response times in compact designs. Emerging trends in fuse technology emphasize smart fuses with integrated sensors for real-time monitoring and predictive maintenance, enhancing reliability and safety in electronic circuits. Your choice of fuse will increasingly benefit from these innovations, ensuring robust protection while supporting IoT and automation demands.

Surface Mount Fuse vs Cartridge Fuse Infographic

libmatt.com

libmatt.com