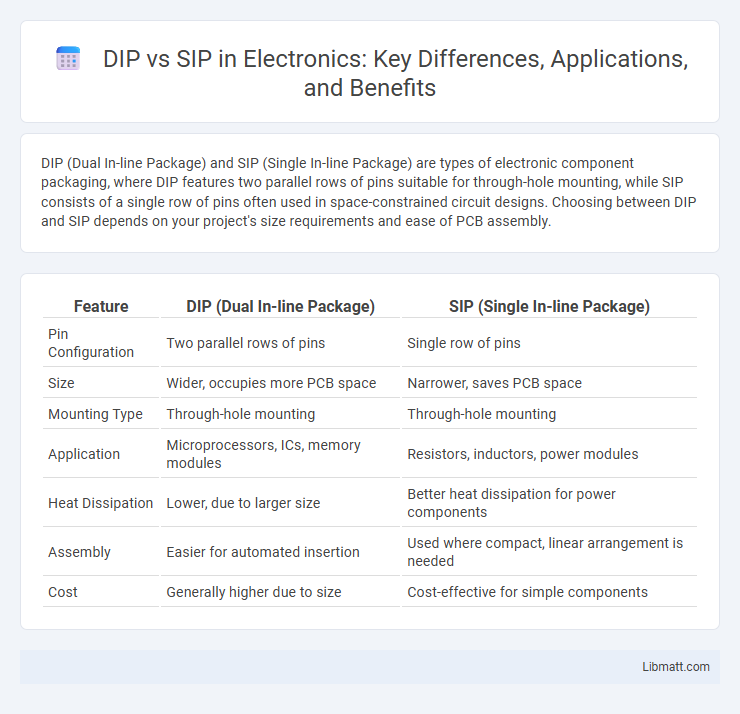

DIP (Dual In-line Package) and SIP (Single In-line Package) are types of electronic component packaging, where DIP features two parallel rows of pins suitable for through-hole mounting, while SIP consists of a single row of pins often used in space-constrained circuit designs. Choosing between DIP and SIP depends on your project's size requirements and ease of PCB assembly.

Table of Comparison

| Feature | DIP (Dual In-line Package) | SIP (Single In-line Package) |

|---|---|---|

| Pin Configuration | Two parallel rows of pins | Single row of pins |

| Size | Wider, occupies more PCB space | Narrower, saves PCB space |

| Mounting Type | Through-hole mounting | Through-hole mounting |

| Application | Microprocessors, ICs, memory modules | Resistors, inductors, power modules |

| Heat Dissipation | Lower, due to larger size | Better heat dissipation for power components |

| Assembly | Easier for automated insertion | Used where compact, linear arrangement is needed |

| Cost | Generally higher due to size | Cost-effective for simple components |

Introduction to DIP and SIP

Dual In-line Package (DIP) and Single In-line Package (SIP) are two common types of integrated circuit packaging used in electronics. DIP features two parallel rows of pins that extend perpendicularly from the package body, allowing easy mounting on printed circuit boards (PCBs) or through-hole sockets. SIP has a single row of pins, which provides a more compact design suited for specific applications requiring linear pin arrangement.

Defining DIP (Direct Inward Dialing Protocol)

Direct Inward Dialing Protocol (DIP) allows multiple phone numbers to ring through to a single physical phone line without requiring an operator or a complex PBX system. DIP efficiently routes calls directly to a specific internal extension, enhancing accessibility and reducing call handling time. Understanding DIP helps you optimize telecommunication systems by enabling seamless direct connections within your organization.

Understanding SIP (Session Initiation Protocol)

Session Initiation Protocol (SIP) is a signaling protocol widely used for initiating, maintaining, and terminating real-time multimedia communication sessions such as voice and video calls over IP networks. SIP establishes, modifies, and terminates multimedia sessions by exchanging signaling messages between endpoints, enabling seamless communication across devices and platforms. Its flexible, text-based architecture supports interoperability and scalability in Voice over IP (VoIP) and unified communications systems.

Key Differences Between DIP and SIP

The key differences between DIP (Dual In-line Package) and SIP (Single In-line Package) lie in their pin configuration and physical layout; DIP components have two parallel rows of pins, enabling more stable mounting and efficient heat dissipation, while SIP components feature a single row of pins, facilitating more compact circuit designs. DIP packages are commonly used in through-hole technology for integrated circuits and microcontrollers, whereas SIP packages are often employed for resistors, capacitors, and connectors where space-saving is essential. The choice between DIP and SIP impacts circuit board design, assembly complexity, and application suitability due to variations in size, pin count, and electrical characteristics.

Architecture Overview: DIP vs SIP

The architecture of Dual In-line Package (DIP) features two parallel rows of pins extending perpendicularly from a rectangular housing, allowing easy insertion into through-hole PCB sockets. In contrast, Single In-line Package (SIP) contains a single row of pins aligned linearly, optimizing space for applications needing fewer connections and simpler layouts. Understanding these structural differences helps you select the appropriate package type for your circuit design and assembly needs.

Use Cases and Applications of DIP

DIP (Dual In-line Package) is widely used in applications requiring easy manual assembly and prototyping, such as microcontrollers, memory chips, and discrete logic circuits in embedded systems. Its through-hole design makes it ideal for educational kits, development boards, and industrial control devices where durability and heat dissipation are critical. SIP (Single In-line Package), in contrast, is preferred in space-constrained devices like telecommunications equipment and compact memory modules due to its linear pin configuration optimizing PCB real estate.

Use Cases and Applications of SIP

SIP (System in Package) technology is widely used in compact devices like smartphones, wearables, and IoT gadgets due to its ability to integrate multiple components into a single module, reducing size and improving performance. It suits applications requiring high-density integration and enhanced signal integrity, such as wireless communication systems, medical devices, and automotive electronics. Your choice of SIP can optimize space and power efficiency in complex, multifunctional electronics compared to traditional DIP (Dual In-line Package) components used mainly in simpler or through-hole applications.

Security Considerations in DIP and SIP

Security considerations in Dual In-line Package (DIP) and Single In-line Package (SIP) integrated circuits vary due to their form factors and applications. DIP components are easier to inspect and replace, offering better physical security against tampering in prototype and low-volume environments, while SIP modules, often used in compact or embedded systems, may require additional protective measures such as conformal coatings or secure enclosures to mitigate risks of physical damage and unauthorized access. Electromagnetic interference (EMI) shielding and secure soldering practices are critical in both DIP and SIP to ensure signal integrity and prevent data leakage in sensitive electronic circuits.

Pros and Cons: DIP vs SIP

DIP (Dual In-line Package) offers easy manual soldering and straightforward prototyping, making it ideal for beginners and small-scale projects, but it consumes more PCB space and is less suited for high-density designs. SIP (Single In-line Package) provides a more compact footprint and simplifies automated assembly processes, though it can be challenging to replace or repair components once soldered. Understanding Your project's requirements for space, assembly, and repair will help determine whether DIP or SIP is the better choice.

Choosing the Right Protocol for Your Business

When choosing between DIP (Device Interface Protocol) and SIP (Session Initiation Protocol) for your business, consider the specific communication needs and network infrastructure. SIP excels in managing multimedia sessions such as voice and video calls, offering flexibility and scalability for VoIP systems and unified communications. DIP, on the other hand, is suited for device-level interactions and embedded systems where low-level control and real-time responsiveness are critical.

DIP vs SIP Infographic

libmatt.com

libmatt.com