Star vs Delta connection refers to two common methods of wiring three-phase motors or transformers, where the star (Y) configuration connects each winding to a common neutral point, resulting in lower voltage and higher current per phase, while the delta (D) connection forms a closed loop, delivering higher voltage and lower current per phase. Choosing the appropriate connection impacts your equipment's starting torque, efficiency, and compatibility with the power supply system.

Table of Comparison

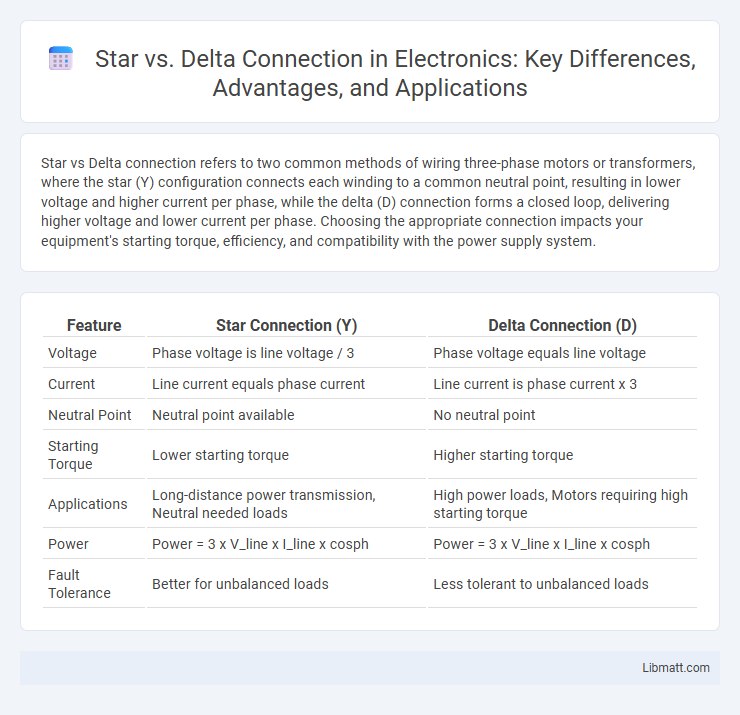

| Feature | Star Connection (Y) | Delta Connection (D) |

|---|---|---|

| Voltage | Phase voltage is line voltage / 3 | Phase voltage equals line voltage |

| Current | Line current equals phase current | Line current is phase current x 3 |

| Neutral Point | Neutral point available | No neutral point |

| Starting Torque | Lower starting torque | Higher starting torque |

| Applications | Long-distance power transmission, Neutral needed loads | High power loads, Motors requiring high starting torque |

| Power | Power = 3 x V_line x I_line x cosph | Power = 3 x V_line x I_line x cosph |

| Fault Tolerance | Better for unbalanced loads | Less tolerant to unbalanced loads |

Introduction to Star and Delta Connections

Star and Delta connections are fundamental wiring configurations used in three-phase electrical systems to connect motor windings or transformers. The Star connection (also called Y-connection) links each coil end to a common neutral point, enabling a phase voltage that is lower than the line voltage and providing a neutral for grounding or return paths. In contrast, the Delta connection forms a closed loop with each coil connected end-to-end, resulting in line voltage equal to phase voltage and allowing higher starting torque in motors or increased power transfer in transformers.

Basic Principle of Star Connection

The basic principle of a star connection involves connecting each phase of a three-phase system to a common neutral point, forming a 'Y' shape. This configuration allows equal voltage distribution across phases, with the line voltage being 3 times the phase voltage, making it ideal for balanced load conditions. Your electrical system benefits from improved stability and easier fault detection with star-connected circuits.

Basic Principle of Delta Connection

The Delta connection in electrical engineering consists of three coils connected end-to-end, forming a closed loop resembling a triangle, which allows current to circulate continuously within the circuit. Each junction point between two coils provides a phase output, resulting in a three-phase system characterized by line voltage equal to phase voltage and line current being the square root of three times the phase current. This configuration is commonly used in power distribution for its ability to deliver high starting torque and handle unbalanced loads with greater efficiency.

Key Differences Between Star and Delta Connections

Star and delta connections differ primarily in their wiring configurations and phase relationships; the star connection features a common neutral point with phase voltage lower than line voltage, while the delta connection forms a closed loop with equal line and phase voltages. In a star connection, current flows through each phase to neutral, resulting in lower current per phase, whereas delta connections allow current to circulate in the loop, supporting higher current and power capacity. Your choice between star and delta impacts efficiency, voltage levels, and suitability for specific applications such as motor starting or heavy load operation.

Advantages of Star Connection

Star connection offers several advantages, including a neutral point that allows the use of both line-to-line and line-to-neutral loads, enhancing system flexibility. It provides lower insulation requirements due to reduced phase voltage compared to line voltage, improving safety and reducing equipment cost. The star connection also enables simpler protection and fault detection mechanisms, making it ideal for various industrial and commercial applications.

Advantages of Delta Connection

Delta connection in three-phase systems offers several advantages, including higher power output and better efficiency under heavy load conditions due to the ability to carry more current. It provides a continuous path for the current even if one phase is lost, enhancing system reliability and fault tolerance. Your electrical system can benefit from smoother operation and reduced voltage drops, making delta connection ideal for industrial motors and high-power applications.

Applications of Star Connection

Star connection is widely applied in electrical distribution systems due to its ability to provide a neutral point, enabling the supply of both single-phase and three-phase power. It is commonly used in transformer windings to facilitate voltage transformation with safer grounding and balanced load distribution. Industrial motors also utilize star connection to reduce starting current and protect against overload.

Applications of Delta Connection

Delta connection is widely used in industrial motors and heavy machinery for its ability to handle high starting torque and continuous heavy loads. It provides a balanced three-phase power supply, making it ideal for applications such as pumps, compressors, and conveyor systems where stable and efficient power delivery is crucial. Your equipment benefits from the delta connection's enhanced power capacity and reliability in demanding operational environments.

Star-Delta Conversion Techniques

Star-Delta conversion techniques involve transforming a three-phase electrical circuit from star (Y) configuration to delta (D) configuration or vice versa, crucial for analyzing complex resistor networks and simplifying circuit calculations. These methods enable the determination of equivalent resistance and facilitate the analysis of three-wire systems by using mathematical formulas to convert resistances between the two configurations. Understanding star-delta conversions helps optimize your electrical designs by ensuring accurate impedance matching and efficient power distribution.

Choosing the Right Connection for Your System

Selecting the appropriate Star or Delta connection depends on your system's voltage requirements, load characteristics, and starting torque needs. Star connections provide a neutral point for stable voltage and are ideal for higher voltage, lower current applications, while Delta connections deliver higher starting torque and are preferred for high power motors. Evaluating your motor's operational demands and power supply configuration ensures optimal performance and energy efficiency.

Star vs Delta Connection Infographic

libmatt.com

libmatt.com