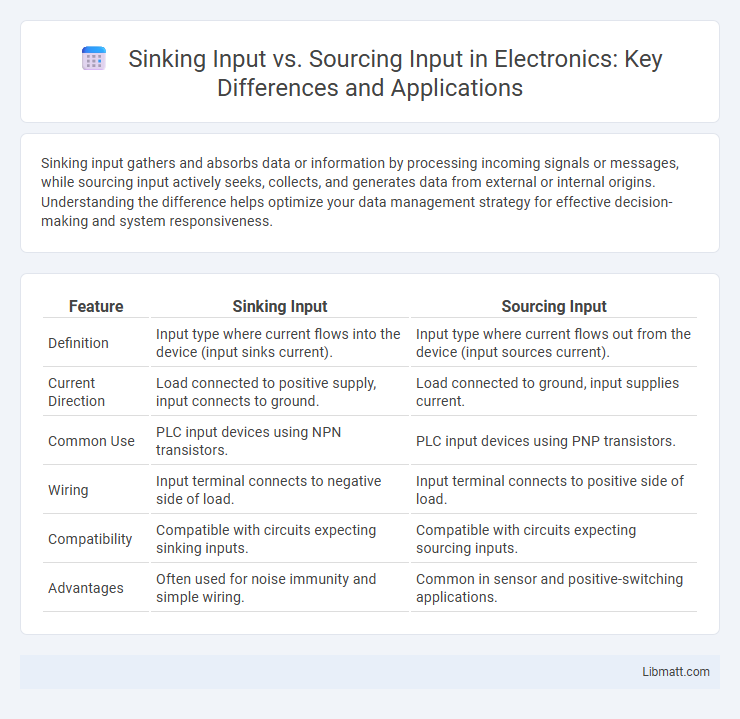

Sinking input gathers and absorbs data or information by processing incoming signals or messages, while sourcing input actively seeks, collects, and generates data from external or internal origins. Understanding the difference helps optimize your data management strategy for effective decision-making and system responsiveness.

Table of Comparison

| Feature | Sinking Input | Sourcing Input |

|---|---|---|

| Definition | Input type where current flows into the device (input sinks current). | Input type where current flows out from the device (input sources current). |

| Current Direction | Load connected to positive supply, input connects to ground. | Load connected to ground, input supplies current. |

| Common Use | PLC input devices using NPN transistors. | PLC input devices using PNP transistors. |

| Wiring | Input terminal connects to negative side of load. | Input terminal connects to positive side of load. |

| Compatibility | Compatible with circuits expecting sinking inputs. | Compatible with circuits expecting sourcing inputs. |

| Advantages | Often used for noise immunity and simple wiring. | Common in sensor and positive-switching applications. |

Understanding Sinking Input and Sourcing Input

Sinking input refers to a device configuration where the input receives current by connecting to a positive voltage source, allowing current to flow from the load through the input device to ground. Sourcing input, on the other hand, occurs when the input provides current to the load by connecting directly to the ground, enabling current flow from the input to the load connected to the positive voltage. Understanding sinking and sourcing inputs helps you select compatible sensors and devices, ensuring proper current flow and preventing circuit malfunctions.

Key Differences Between Sinking Input and Sourcing Input

Sinking input in digital circuits involves a device drawing current from the circuit, effectively acting as a current sink, while sourcing input means the device provides or supplies current to the circuit, functioning as a current source. The key differences lie in current direction; sinking inputs pull current through the input terminal to ground, whereas sourcing inputs push current out from the power supply through the input terminal. These distinctions impact circuit design considerations such as voltage levels, interface compatibility, and power consumption, emphasizing the importance of matching sinking or sourcing inputs with corresponding outputs.

How Sinking Input Works in Electrical Circuits

Sinking input in electrical circuits refers to a configuration where the input device provides a path to ground, allowing current to flow into the circuit from the input source. This setup is common in digital and industrial control systems where the input device "sinks" current when activated, typically connecting the load to a low voltage or ground reference. The sinking input effectively completes the circuit by drawing current through the input device to ground, enabling the controller or input card to detect the signal.

Role of Sourcing Input in Automation Systems

Sourcing input provides a positive voltage to the load, ensuring a reliable and noise-immune signal in automation systems. It is essential for enabling precise control in PLCs and sensors, where consistent voltage sourcing prevents false triggers and enhances system stability. The choice of sourcing input is critical for achieving efficient and accurate operation in industrial automation environments.

Advantages of Using Sinking Input

Sinking input offers precise control over signal voltage levels by allowing devices to complete the circuit to ground, which reduces noise and enhances reliability in industrial automation systems. This approach simplifies wiring, improves interoperability with a wide range of sensors, and often results in lower power consumption compared to sourcing input configurations. Using sinking input can enhance your system's overall performance by providing clear, stable signal detection in complex environments.

Benefits of Sourcing Input in Industrial Applications

Sourcing input provides a reliable method to control devices by supplying current to the load, enhancing safety and reducing wiring complexity in industrial applications. This approach ensures stable circuit operation with less susceptibility to noise and voltage drops, improving overall system efficiency and equipment lifespan. Your industrial setup benefits from precise control and easier troubleshooting, making sourcing input ideal for automation and control systems.

Common Misconceptions About Sinking and Sourcing Inputs

Common misconceptions about sinking and sourcing inputs include confusing their roles in current flow direction, where sinking inputs absorb current (NPN) and sourcing inputs provide current (PNP). Many believe both input types are interchangeable without considering compatibility with the control system's voltage and wiring requirements. Understanding your device's input configuration ensures proper connection and avoids potential circuit malfunctions or damage.

Choosing Between Sinking and Sourcing Inputs

Choosing between sinking and sourcing inputs depends on the logic and voltage requirements of the control system. Sinking input configurations connect the load to the positive voltage through the input device, suitable for systems designed with NPN transistor outputs. Sourcing inputs, on the other hand, supply current to the load from the positive voltage, aligning with PNP transistor outputs and providing higher noise immunity in industrial environments.

Safety Considerations for Sinking vs Sourcing Input

Safety considerations for sinking vs sourcing input focus on ensuring proper current flow to prevent electrical hazards and equipment damage. Sinking input devices connect the load to the negative side of the power supply, reducing the risk of short circuits and providing better isolation from noise, while sourcing inputs connect to the positive side, which can increase the chance of accidental shorts if wiring errors occur. Your control system's safety is enhanced by selecting the appropriate input type based on the voltage level, grounding scheme, and load requirements to minimize electrical faults and ensure reliable operation.

Practical Applications: Sinking Input vs Sourcing Input

Sinking input and sourcing input are essential concepts in industrial automation, each serving distinct practical applications in control systems. Sinking input refers to devices that provide a path to ground, commonly used for sensors or switches sourcing a positive voltage, while sourcing input devices supply voltage to the control system, ideal for applications requiring current flow into the input module. Understanding whether your setup requires sinking or sourcing input ensures compatibility and efficient operation of PLCs and control circuits in manufacturing, process control, and safety monitoring systems.

Sinking Input vs Sourcing Input Infographic

libmatt.com

libmatt.com