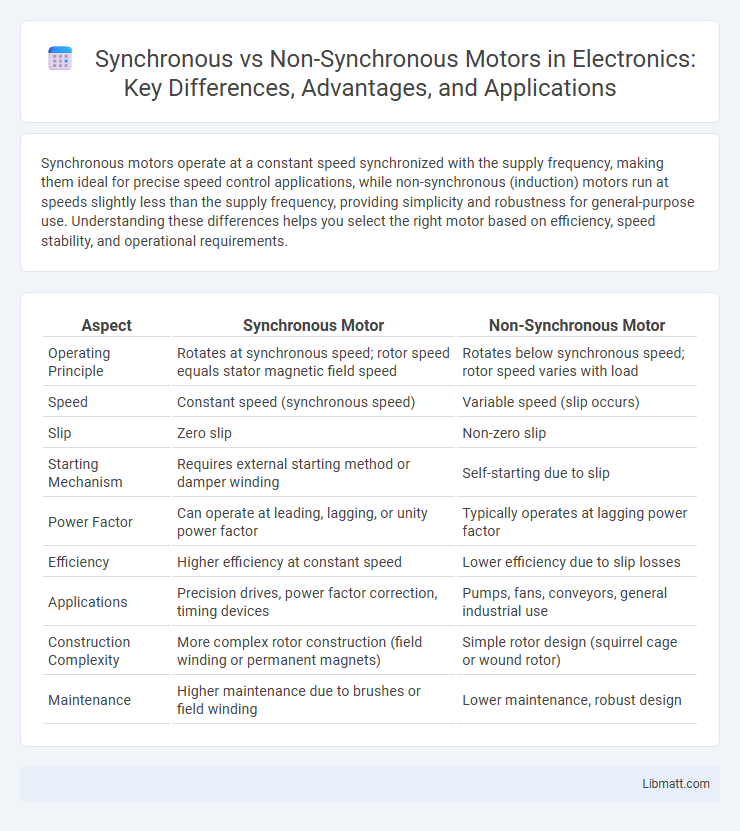

Synchronous motors operate at a constant speed synchronized with the supply frequency, making them ideal for precise speed control applications, while non-synchronous (induction) motors run at speeds slightly less than the supply frequency, providing simplicity and robustness for general-purpose use. Understanding these differences helps you select the right motor based on efficiency, speed stability, and operational requirements.

Table of Comparison

| Aspect | Synchronous Motor | Non-Synchronous Motor |

|---|---|---|

| Operating Principle | Rotates at synchronous speed; rotor speed equals stator magnetic field speed | Rotates below synchronous speed; rotor speed varies with load |

| Speed | Constant speed (synchronous speed) | Variable speed (slip occurs) |

| Slip | Zero slip | Non-zero slip |

| Starting Mechanism | Requires external starting method or damper winding | Self-starting due to slip |

| Power Factor | Can operate at leading, lagging, or unity power factor | Typically operates at lagging power factor |

| Efficiency | Higher efficiency at constant speed | Lower efficiency due to slip losses |

| Applications | Precision drives, power factor correction, timing devices | Pumps, fans, conveyors, general industrial use |

| Construction Complexity | More complex rotor construction (field winding or permanent magnets) | Simple rotor design (squirrel cage or wound rotor) |

| Maintenance | Higher maintenance due to brushes or field winding | Lower maintenance, robust design |

Introduction to Synchronous and Non-Synchronous Motors

Synchronous motors operate at a constant speed synchronized with the power supply frequency, making them ideal for applications requiring precise speed control. Non-synchronous motors, commonly known as induction motors, run at speeds slightly less than the supply frequency and are widely used due to their robust construction and cost-effectiveness. Understanding the differences between synchronous and non-synchronous motors helps you select the right motor for efficiency and performance in your specific application.

Basic Working Principles

Synchronous motors operate by rotating at a constant speed synchronized with the frequency of the supply current, using a rotor energized by a DC source to create a stable magnetic field. Non-synchronous motors, such as induction motors, run at speeds slightly less than the supply frequency, where the rotor current is induced by the stator's rotating magnetic field without requiring external excitation. The key difference lies in speed control: synchronous motors maintain constant speed under varying loads, while non-synchronous motors experience slip, causing variable rotor speed.

Construction Differences

Synchronous motors feature a rotor with permanent magnets or a salient pole winding that rotates at the same speed as the stator's rotating magnetic field, ensuring constant synchronous speed. Non-synchronous (induction) motors have a rotor made of laminated iron cores with conductors, such as squirrel cages, which rotate at a speed slightly less than the synchronous speed, creating slip for torque production. The construction of synchronous motors requires precise rotor windings or magnets for synchronization, while induction motors rely on induced current in the rotor without external excitation.

Operational Speed Characteristics

Synchronous motors operate at a constant speed directly proportional to the supply frequency, maintaining synchronous speed under varying loads without slip. Non-synchronous motors, such as induction motors, run at speeds slightly less than synchronous speed, with slip increasing as load increases to produce torque. This fundamental difference defines their suitability for applications requiring precise speed control versus those accommodating variable speeds.

Efficiency Comparison

Synchronous motors generally offer higher efficiency compared to non-synchronous (induction) motors due to their ability to operate at a constant speed with minimal rotor losses. Non-synchronous motors experience more slip, resulting in additional energy loss and lower overall efficiency, especially under variable load conditions. Your choice between the two should consider the efficiency benefits of synchronous motors for steady-speed applications and the simplicity of induction motors for variable-speed or cost-sensitive scenarios.

Applications in Industry

Synchronous motors are commonly used in industries requiring precise speed control and constant speed operation, such as robotics, conveyor systems, and manufacturing equipment. Non-synchronous motors, like induction motors, dominate applications needing variable speed and high starting torque, like pumps, fans, and compressors. Your choice between these motors depends on the specific industrial application demands, balancing efficiency, speed regulation, and load characteristics.

Advantages of Synchronous Motors

Synchronous motors offer precise speed control and high efficiency, making them ideal for applications requiring constant speed under varying loads. They provide excellent power factor correction, improving overall system efficiency and reducing energy costs. Your industrial processes can benefit from their ability to operate at synchronous speed without slip, ensuring consistent performance and reduced maintenance.

Advantages of Non-Synchronous Motors

Non-synchronous motors, including induction motors, offer advantages such as simpler construction, lower manufacturing costs, and higher reliability due to the absence of brushes and slip rings. They provide robust operation under varying load conditions with inherent overload protection and require less maintenance compared to synchronous motors. Their ability to self-start without external excitation makes them ideal for diverse industrial applications where ease of use and durability are critical.

Key Limitations of Both Types

Synchronous motors face limitations such as complexity in starting mechanisms and inability to self-start without auxiliary devices, leading to higher initial costs and maintenance challenges. Non-synchronous motors, primarily induction motors, suffer from slip energy losses and reduced efficiency at varying loads, which impact performance consistency. Both types have operational constraints influenced by factors like speed control precision and power factor variation under different load conditions.

Choosing the Right Motor for Specific Needs

Selecting between synchronous and non-synchronous motors depends on the application's precision and speed requirements. Synchronous motors provide constant speed and high efficiency, ideal for applications needing precise timing, such as robotics and conveyor systems. Non-synchronous (induction) motors offer robustness and simplicity, making them suitable for variable-speed tasks like pumps, fans, and compressors.

Synchronous vs Non-synchronous motor Infographic

libmatt.com

libmatt.com