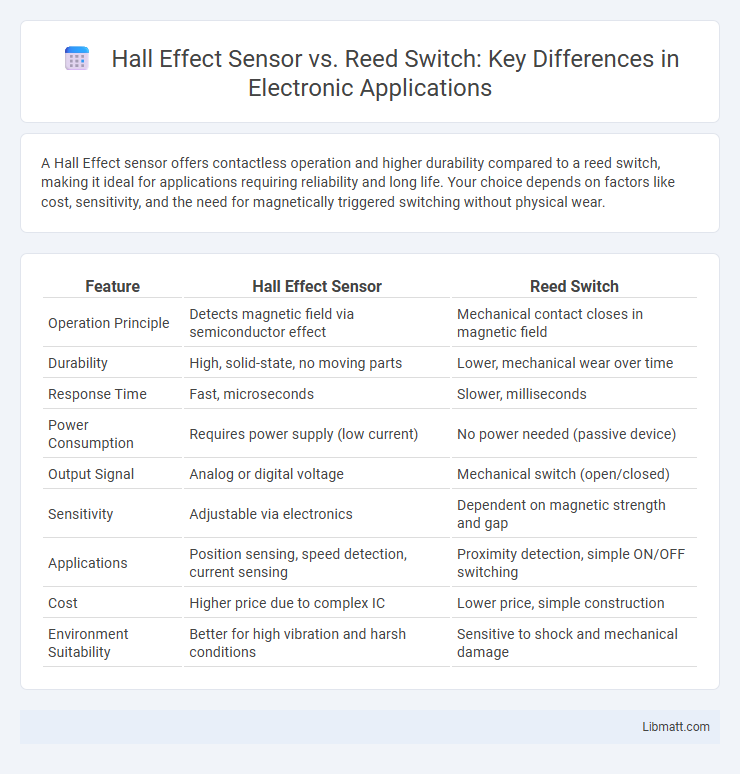

A Hall Effect sensor offers contactless operation and higher durability compared to a reed switch, making it ideal for applications requiring reliability and long life. Your choice depends on factors like cost, sensitivity, and the need for magnetically triggered switching without physical wear.

Table of Comparison

| Feature | Hall Effect Sensor | Reed Switch |

|---|---|---|

| Operation Principle | Detects magnetic field via semiconductor effect | Mechanical contact closes in magnetic field |

| Durability | High, solid-state, no moving parts | Lower, mechanical wear over time |

| Response Time | Fast, microseconds | Slower, milliseconds |

| Power Consumption | Requires power supply (low current) | No power needed (passive device) |

| Output Signal | Analog or digital voltage | Mechanical switch (open/closed) |

| Sensitivity | Adjustable via electronics | Dependent on magnetic strength and gap |

| Applications | Position sensing, speed detection, current sensing | Proximity detection, simple ON/OFF switching |

| Cost | Higher price due to complex IC | Lower price, simple construction |

| Environment Suitability | Better for high vibration and harsh conditions | Sensitive to shock and mechanical damage |

Introduction to Magnetic Sensors

Magnetic sensors detect magnetic fields and convert them into electrical signals for various applications, with the Hall Effect sensor and Reed switch being two common types. Hall Effect sensors utilize the Hall voltage generated by a conductor in a magnetic field, providing precise, contactless measurements ideal for speed and position sensing. Reed switches operate with magnetic field-induced mechanical movement of ferromagnetic reeds, offering simple, reliable switching for proximity and security systems.

What is a Hall Effect Sensor?

A Hall Effect sensor is a semiconductor device that detects magnetic fields and converts their presence into an electrical signal, enabling precise position, speed, and current sensing in various applications. It operates by measuring the voltage difference generated perpendicular to the direction of current flow in a conductor affected by a magnetic field. Unlike mechanical reed switches, Hall Effect sensors offer higher durability, faster response time, and greater reliability in harsh environments.

What is a Reed Switch?

A Reed Switch is an electrical switch operated by an applied magnetic field, consisting of two ferromagnetic reeds enclosed in a glass tube that close or open the circuit when exposed to magnetism. Unlike Hall Effect Sensors, Reed Switches are mechanical and rely on physical contact, which can result in wear over time but also provide a simple and reliable method for detecting magnetic fields. You benefit from their low power consumption and robustness in various applications such as proximity sensing and security systems.

Working Principles: Hall Effect vs Reed Switch

Hall Effect sensors operate by detecting changes in magnetic fields through the generation of a voltage difference across an electrical conductor, utilizing the Lorentz force on charge carriers. Reed switches function by physically closing or opening electrical contacts when exposed to a magnetic field, employing ferromagnetic reeds sealed in a glass envelope. The Hall Effect sensor offers contactless operation with high reliability, whereas the reed switch relies on mechanical movement and physical contact for signal switching.

Key Differences in Design and Construction

Hall Effect Sensors use semiconductor materials to detect magnetic fields through changes in voltage, offering solid-state construction with no moving parts, while Reed Switches consist of two ferromagnetic blades sealed in a glass tube that physically close when exposed to a magnetic field. Hall Effect Sensors provide higher reliability and longer lifespan due to their durable, non-mechanical design, whereas Reed Switches are simpler and more cost-effective but prone to mechanical wear. Understanding these construction differences helps you choose the right sensor based on your application's durability and precision requirements.

Sensitivity and Response Time Comparison

Hall effect sensors offer higher sensitivity and faster response times compared to reed switches, detecting magnetic fields as low as a few gauss with response times in microseconds. Reed switches typically require stronger magnetic fields to activate, around 10 to 50 gauss, and exhibit slower response times in the milliseconds range due to mechanical movement. Your choice between these sensors depends on the precision and speed needed for applications such as proximity sensing or speed detection.

Durability and Reliability Aspects

Hall effect sensors offer superior durability compared to reed switches due to their solid-state design, which eliminates mechanical wear and tear. Reed switches, relying on physical contacts, are more prone to failure from repeated mechanical stress and environmental factors such as vibration and humidity. Choosing a Hall effect sensor enhances your system's reliability by providing consistent performance in harsh conditions without degradation over time.

Common Applications of Hall Effect Sensors and Reed Switches

Hall effect sensors are widely used in automotive ignition systems, brushless DC motor control, and position sensing due to their high sensitivity and durability in harsh environments. Reed switches find common applications in security systems, such as door and window alarms, and in proximity sensing for appliances because of their simple, reliable contact-based operation. Your choice between the two depends on the need for contactless sensing with fast response or a mechanical switch for cost-effective, low-power detection.

Pros and Cons: Hall Effect Sensors vs Reed Switches

Hall Effect sensors offer high durability and precise magnetic field detection without physical contact, making them ideal for applications requiring long lifespan and reliability, but they generally require a power source and can be more expensive. Reed switches are simple, low-cost, and operate with minimal power consumption, making them suitable for basic on/off magnetic sensing tasks; however, they have mechanical parts that can wear out over time and are less precise than Hall Effect sensors. Choosing between these depends on your specific needs for accuracy, durability, power availability, and budget constraints.

Choosing the Right Sensor for Your Application

Hall Effect Sensors offer precise, contactless detection ideal for high-speed and harsh environmental conditions, while Reed Switches provide a cost-effective, simple solution for low-frequency, mechanical applications. Your choice depends on factors like response time, durability, power consumption, and environmental exposure. Opt for Hall Effect Sensors when accuracy and longevity matter, and select Reed Switches for straightforward, budget-friendly implementations.

Hall Effect Sensor vs Reed Switch Infographic

libmatt.com

libmatt.com