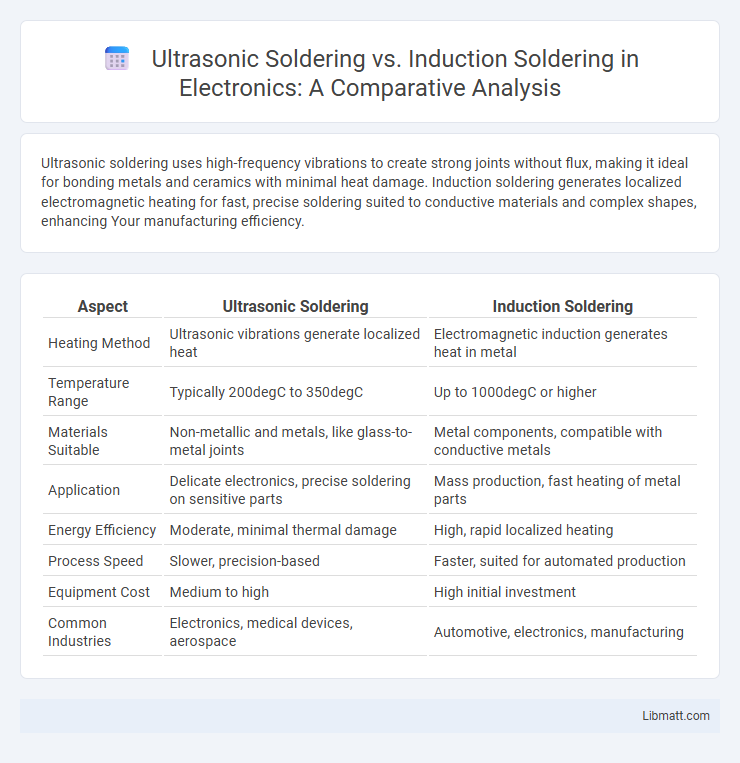

Ultrasonic soldering uses high-frequency vibrations to create strong joints without flux, making it ideal for bonding metals and ceramics with minimal heat damage. Induction soldering generates localized electromagnetic heating for fast, precise soldering suited to conductive materials and complex shapes, enhancing Your manufacturing efficiency.

Table of Comparison

| Aspect | Ultrasonic Soldering | Induction Soldering |

|---|---|---|

| Heating Method | Ultrasonic vibrations generate localized heat | Electromagnetic induction generates heat in metal |

| Temperature Range | Typically 200degC to 350degC | Up to 1000degC or higher |

| Materials Suitable | Non-metallic and metals, like glass-to-metal joints | Metal components, compatible with conductive metals |

| Application | Delicate electronics, precise soldering on sensitive parts | Mass production, fast heating of metal parts |

| Energy Efficiency | Moderate, minimal thermal damage | High, rapid localized heating |

| Process Speed | Slower, precision-based | Faster, suited for automated production |

| Equipment Cost | Medium to high | High initial investment |

| Common Industries | Electronics, medical devices, aerospace | Automotive, electronics, manufacturing |

Introduction to Soldering Technologies

Ultrasonic soldering employs high-frequency ultrasonic vibrations to create strong, flux-free bonds on difficult-to-solder materials like ceramics and glass, ensuring precision in electronics manufacturing. Induction soldering uses electromagnetic induction to rapidly heat metallic components, providing controlled, localized soldering ideal for mass production and industrial applications. Choosing the right technology depends on Your material compatibility, production volume, and the required joint quality.

Overview of Ultrasonic Soldering

Ultrasonic soldering uses high-frequency vibrations to clean and activate metal surfaces without flux, enabling strong bonds with difficult-to-solder materials like ceramics and glass. This technique generates localized ultrasonic energy that breaks down oxide layers, improving wettability and joint reliability. Your production benefits from reduced contamination and enhanced solder joint quality compared to traditional soldering methods.

Fundamentals of Induction Soldering

Induction soldering uses electromagnetic fields to generate localized heat within conductive materials, enabling precise and efficient melting of solder without direct contact. The process relies on induction coils to create high-frequency currents, which induce resistance heating in the workpiece, making it ideal for rapid and clean solder joints in repetitive manufacturing environments. Understanding these fundamentals of induction soldering allows you to optimize thermal control and improve the reliability of your electronic assemblies.

Key Differences Between Ultrasonic and Induction Soldering

Ultrasonic soldering uses high-frequency vibrations to clean and activate metal surfaces without flux, enabling strong bonds on materials like glass, ceramics, and plastics, while induction soldering relies on electromagnetic fields to heat and melt solder through conductive materials quickly and efficiently. Ultrasonic soldering excels in joining dissimilar or non-metallic substrates with minimal thermal stress, whereas induction soldering is preferred for high-volume, precise heating of metal assemblies with controlled temperature zones. The main difference lies in the heating mechanism--mechanical vibrations versus electromagnetic induction--and their applications in materials compatibility, process speed, and thermal management.

Advantages of Ultrasonic Soldering

Ultrasonic soldering offers precise temperature control and the ability to solder materials with poor thermal conductivity or without flux, ensuring strong, clean joints on metals, ceramics, and glass. It minimizes thermal damage and oxidation by using high-frequency vibrations, which improve wettability and solder flow, enhancing the reliability and durability of your electronic assemblies. Compared to induction soldering, ultrasonic soldering is more versatile for delicate components and complex geometries, reducing rework and improving overall production efficiency.

Benefits of Induction Soldering

Induction soldering offers precise, rapid heating with minimal thermal stress, enhancing joint reliability and reducing cycle times in manufacturing. Its contactless nature ensures consistent temperature control and uniform heating, which improves the quality of soldered connections on delicate or complex components. You benefit from energy efficiency and automation compatibility, making induction soldering ideal for high-volume production environments requiring repeatable and clean solder joints.

Applications of Ultrasonic Soldering

Ultrasonic soldering is ideal for joining dissimilar metals, ceramics, and glass components where traditional flux-based methods fail, making it essential in electronics, aerospace, and medical device manufacturing. Its ability to create strong, clean bonds without flux or extensive surface preparation enhances reliability in precision assemblies like sensors and circuit boards. Your choice of ultrasonic soldering can improve joint durability and performance in applications requiring contamination-free, high-strength connections.

Applications of Induction Soldering

Induction soldering is widely used in the automotive, aerospace, and electronics industries for precise, rapid, and clean joining of components, especially in mass production environments. Its applications include soldering gears, connectors, circuit boards, and metallic tubes, where localized heating minimizes thermal stress on sensitive parts. Your manufacturing process benefits from induction soldering's ability to deliver consistent, repeatable solder joints with high energy efficiency and minimal oxidation.

Factors to Consider When Choosing a Soldering Method

Choosing between ultrasonic soldering and induction soldering depends on material compatibility, joint precision, and thermal sensitivity. Ultrasonic soldering excels with difficult metals and provides strong bonds without flux, ideal for delicate electronics or glass-to-metal joints. Induction soldering offers high-speed, localized heating suited for mass production and metals with good electrical conductivity.

Conclusion: Selecting the Optimal Soldering Technique

Ultrasonic soldering excels in bonding difficult metals and delicate components by using high-frequency vibrations to remove oxides without flux, ideal for electronics and precision applications. Induction soldering offers rapid, localized heating through electromagnetic fields, making it suitable for high-volume manufacturing and metals with high thermal conductivity. Choosing between these methods depends on material compatibility, production scale, and the specific thermal requirements of the soldering task.

Ultrasonic Soldering vs Induction Soldering Infographic

libmatt.com

libmatt.com