Air core inductors offer higher frequency performance and minimal core losses, making them ideal for RF applications, while iron core inductors provide greater inductance and energy storage capacity, suitable for low-frequency and power applications. Choosing between the two depends on Your circuit requirements, balancing factors like frequency range, efficiency, and size.

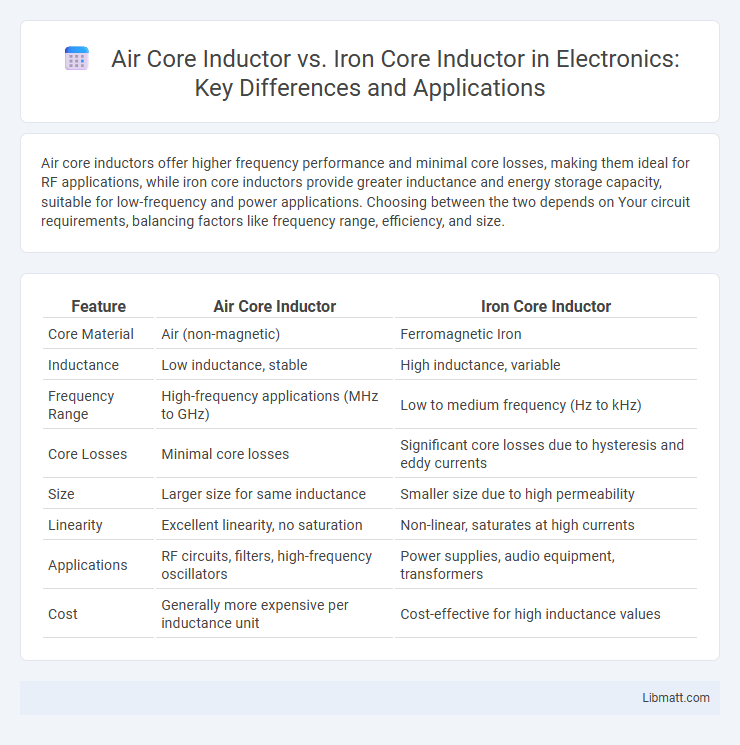

Table of Comparison

| Feature | Air Core Inductor | Iron Core Inductor |

|---|---|---|

| Core Material | Air (non-magnetic) | Ferromagnetic Iron |

| Inductance | Low inductance, stable | High inductance, variable |

| Frequency Range | High-frequency applications (MHz to GHz) | Low to medium frequency (Hz to kHz) |

| Core Losses | Minimal core losses | Significant core losses due to hysteresis and eddy currents |

| Size | Larger size for same inductance | Smaller size due to high permeability |

| Linearity | Excellent linearity, no saturation | Non-linear, saturates at high currents |

| Applications | RF circuits, filters, high-frequency oscillators | Power supplies, audio equipment, transformers |

| Cost | Generally more expensive per inductance unit | Cost-effective for high inductance values |

Introduction to Air Core and Iron Core Inductors

Air core inductors utilize non-magnetic materials like plastic or air as the core, resulting in low inductance values and minimal core losses at high frequencies. Iron core inductors employ a ferromagnetic core, significantly increasing inductance due to the higher magnetic permeability of iron, making them suitable for low-frequency applications requiring higher energy storage. The choice between air core and iron core inductors depends on factors such as operating frequency, inductance requirements, and efficiency considerations.

Construction and Design Differences

Air core inductors feature a coil wound around a non-magnetic, hollow form, eliminating the need for a magnetic core, which results in low inductance values and minimal core losses. Iron core inductors incorporate a ferromagnetic core material such as laminated iron or ferrite, enhancing magnetic permeability and inductance, but adding core losses and potential saturation issues. The construction of air core inductors prioritizes frequency response and stability, while iron core inductors focus on maximizing inductance and energy storage within a compact design.

Magnetic Core Materials: Air vs Iron

Air core inductors utilize non-magnetic materials such as air or plastic as their core, resulting in low inductance values and virtually no core losses, making them ideal for high-frequency applications. Iron core inductors contain ferromagnetic materials like laminated silicon steel or ferrite, which provide high magnetic permeability and greater inductance but suffer from core losses and potential saturation at high currents. The choice between air and iron core materials directly impacts inductance stability, efficiency, frequency response, and saturation characteristics in inductive components.

Inductance Value Comparison

Air core inductors typically exhibit lower inductance values compared to iron core inductors due to the absence of a ferromagnetic material that enhances magnetic permeability. Iron core inductors achieve higher inductance by concentrating the magnetic flux within the iron core, which significantly increases flux linkage and energy storage capacity. Consequently, for applications requiring high inductance and compact size, iron core inductors are preferred, while air core inductors are chosen for high-frequency or low-inductance scenarios due to their lower core losses and linearity.

Frequency Response and Performance

Air core inductors exhibit superior high-frequency response due to the absence of core losses and magnetic saturation, making them ideal for RF and high-frequency applications. Iron core inductors, however, provide higher inductance values and better energy storage at lower frequencies but suffer from core losses and reduced efficiency at high frequencies. Performance-wise, air core inductors offer lower inductance but greater linearity and stability, while iron core inductors excel in power handling and low-frequency signal filtering.

Efficiency and Energy Loss

Air core inductors offer higher efficiency in high-frequency applications due to their negligible core losses, as they lack a magnetic core that generates eddy currents and hysteresis losses. Iron core inductors, while providing greater inductance and magnetic flux concentration, often experience increased energy losses caused by core saturation and hysteresis, reducing their efficiency especially at higher frequencies. To optimize your circuit's performance, choosing an air core inductor minimizes energy loss where efficiency is critical, whereas iron core inductors suit low-frequency applications demanding stronger magnetic fields.

Applications in Electronics

Air core inductors are primarily used in high-frequency applications such as radio transmitters, RF circuits, and signal processing due to their low core losses and minimal magnetic interference. Iron core inductors excel in power electronics and audio devices where higher inductance and stronger magnetic fields are required, including transformers, power supplies, and inductive load filters. The choice between air core and iron core inductors depends on the frequency, power handling, and efficiency demands of the specific electronic application.

Size, Weight, and Cost Factors

Air core inductors are typically smaller and lighter than iron core inductors due to the absence of heavy magnetic materials. Iron core inductors offer higher inductance values but come with increased size and weight, impacting portability and integration in compact designs. Cost-wise, air core inductors are generally more expensive to manufacture because of precision winding requirements, whereas iron core inductors benefit from lower material costs despite their bulk.

Advantages and Disadvantages

Air core inductors offer advantages such as minimal core losses and high linearity, making them ideal for high-frequency applications, while their disadvantages include lower inductance values and larger physical size compared to iron core inductors. Iron core inductors provide higher inductance and compact size due to the high permeability of the iron core, but they suffer from core losses, hysteresis, and saturation issues, limiting their performance at high frequencies. Choosing the right inductor depends on your application's frequency range, size constraints, and inductance requirements.

Choosing the Right Inductor for Your Project

Air core inductors offer low core losses and high-frequency performance, making them ideal for high-frequency circuits and RF applications. Iron core inductors provide higher inductance and better energy storage due to their magnetic core, suited for power supply and audio equipment. Understanding your project's frequency requirements and inductance values will help you select the right inductor for optimal performance and efficiency.

Air Core Inductor vs Iron Core Inductor Infographic

libmatt.com

libmatt.com