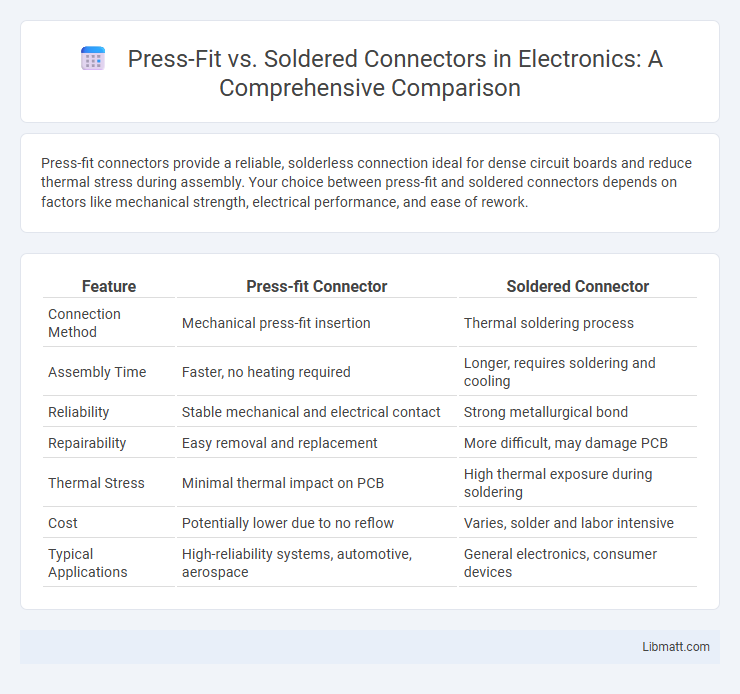

Press-fit connectors provide a reliable, solderless connection ideal for dense circuit boards and reduce thermal stress during assembly. Your choice between press-fit and soldered connectors depends on factors like mechanical strength, electrical performance, and ease of rework.

Table of Comparison

| Feature | Press-fit Connector | Soldered Connector |

|---|---|---|

| Connection Method | Mechanical press-fit insertion | Thermal soldering process |

| Assembly Time | Faster, no heating required | Longer, requires soldering and cooling |

| Reliability | Stable mechanical and electrical contact | Strong metallurgical bond |

| Repairability | Easy removal and replacement | More difficult, may damage PCB |

| Thermal Stress | Minimal thermal impact on PCB | High thermal exposure during soldering |

| Cost | Potentially lower due to no reflow | Varies, solder and labor intensive |

| Typical Applications | High-reliability systems, automotive, aerospace | General electronics, consumer devices |

Introduction to Connector Technologies

Press-fit connectors utilize a mechanical interference fit to establish reliable electrical contacts without solder, enabling easy rework and reducing thermal stress on PCBs. Soldered connectors depend on molten solder to form permanent, electrically conductive joints that provide strong mechanical stability and excellent electrical conductivity. Both technologies serve critical roles in electronic assemblies, with press-fit favoring high-density, lead-free manufacturing and soldered connectors offering proven durability in diverse applications.

Overview of Press-fit Connectors

Press-fit connectors provide a reliable, solderless method for establishing electrical connections on printed circuit boards by mechanically deforming the connector pins into plated through-holes, ensuring gas-tight and durable contacts. These connectors offer advantages such as reduced thermal stress on components, increased manufacturing efficiency, and the ability to accommodate high-density PCB layouts. Widely used in automotive, telecommunications, and industrial applications, press-fit technology supports high vibration resistance and long-term electrical integrity compared to traditional soldered connections.

Overview of Soldered Connectors

Soldered connectors provide a reliable, permanent electrical connection by melting solder to join the connector pins to the PCB pads, ensuring low resistance and strong mechanical stability. These connectors are favored in applications requiring high durability and consistent signal integrity, such as in aerospace, automotive, and industrial electronics. Your devices benefit from soldered connectors by maintaining robust performance under vibration and thermal cycling conditions.

Key Differences Between Press-fit and Soldered Connectors

Press-fit connectors create reliable electrical and mechanical connections through a friction fit, eliminating the need for solder and enabling faster, more environmentally friendly assembly processes. Soldered connectors rely on molten solder to form a permanent bond, offering high conductivity and mechanical strength but requiring heat and more time during manufacturing. Press-fit technology reduces thermal stress on components and is ideal for automated assembly in high-volume PCB production, whereas soldered connections provide proven durability in demanding electrical applications.

Electrical Performance Comparison

Press-fit connectors provide reliable electrical performance with consistent contact resistance due to their gas-tight connections, minimizing signal loss and interference. Soldered connectors typically offer lower electrical resistance and superior conductivity, ensuring stable signal integrity under high-frequency applications. Your choice depends on balancing ease of assembly with the need for optimal electrical performance in demanding electronic environments.

Mechanical Reliability and Durability

Press-fit connectors offer superior mechanical reliability due to their gas-tight, pressure-based contact, which eliminates solder joint fatigue and cracks caused by thermal cycling. These connectors provide enhanced durability in high-vibration environments, maintaining electrical integrity without degradation over time. In contrast, soldered connectors are prone to joint failure under mechanical stress and repeated thermal expansion, reducing long-term reliability and increasing maintenance requirements.

Assembly and Manufacturing Considerations

Press-fit connectors enable quick, solderless assembly by relying on compliant pins that create reliable mechanical and electrical connections, reducing manufacturing time and heat exposure to components. Soldered connectors require precise soldering processes, which can extend assembly time and introduce thermal stress, but offer excellent mechanical strength and long-term connection stability. Your choice impacts production efficiency, with press-fit favored for ease and speed, while soldered connectors suit applications demanding robust, vibration-resistant joints.

Cost Analysis: Press-fit vs Soldered

Press-fit connectors generally reduce assembly costs by eliminating the need for wave or reflow soldering equipment and processes, which lowers labor and energy expenses. Soldered connectors, while typically offering more reliable mechanical and electrical bonds, incur higher manufacturing costs due to solder materials, additional process steps, and longer cycle times. Choosing press-fit technology can significantly decrease expenses in high-volume production but may require design considerations to ensure long-term performance and durability.

Typical Applications for Each Connector Type

Press-fit connectors are commonly used in high-reliability applications such as automotive electronics and industrial machinery, where vibration resistance and ease of assembly are critical. Soldered connectors are preferred in consumer electronics and telecommunications equipment due to their strong mechanical bonds and excellent electrical conductivity. Both connector types serve distinct purposes based on production volume, environmental conditions, and maintenance requirements.

Choosing the Right Connector: Factors to Consider

Selecting between press-fit and soldered connectors depends on factors such as assembly speed, mechanical reliability, and rework requirements. Press-fit connectors offer quick installation and strong mechanical stability without heat, ideal for sensitive components, while soldered connectors provide robust electrical conductivity and long-term durability in harsh environments. Evaluating your board design, production volume, and maintenance needs ensures you choose the connector that optimizes performance and cost-efficiency.

Press-fit vs Soldered connector Infographic

libmatt.com

libmatt.com